How to Choose the Right Leak Testing Equipment for Your Application

Leave a CommentLeak testing processes ensure the high-quality, consistent performance of products that need to provide a reliable seal at a set pressure level. However, there are many different types of leak tests, such as helium leak tests, mass extraction tests, and more. At AMD, we provide automation and manufacturing solutions for a wide variety of components […]

ROIC Considerations of Industrial Automation Equipment for Manufacturing

Leave a CommentAutomation equipment can deliver significant value to manufacturing companies if done right. Automation projects should always be justified from a financial standpoint, so it’s important to select a solution that fulfills production needs while being able to minimize costs over the long term. At Advanced Manufacturing Development (AMD), our team has more than 25 years […]

The Ins and Outs of Helium Leak Testing Equipment

2 CommentsLeak testing is critical to manufacturing quality assurance practices and functionality testing for a broad range of pressurized equipment. While there are many leak detection methods, helium vacuum tests offer superior sensitivity and accuracy for identifying common leaks and micro-leaks. Why Use Helium Leak Testing Equipment? Helium leak testing equipment offers a means to detect […]

Tags: Helium Accumulation, Helium Hard Vacuum, Helium Leak Testing, Helium Leak Testing Equipment, Helium Sniffing

Automated Assembly Machines: A Selection Guide

Leave a CommentAssembly line automation allows companies to meet high production demands by performing assembly processes without the intervention of a human operator and moving parts along automated process sequences. Due to the large variety of products that need to be assembled and the different processes each assembly involves, automated assembly machines are almost always custom designed, […]

Automation and the Future of Appliance Manufacturing

Leave a CommentAssembly machines and robotic technology contribute significantly to the appliance manufacturing industry. They’re highly effective in smaller assembly applications, putting together household appliances like toasters, irons, or vacuum cleaners. However, for companies that manufacture high volumes of large white goods like clothes washers or refrigerators, in many cases, robots currently handle only those tasks that […]

Understanding and Reducing Automation Lead Times

Leave a CommentWhat are lead times? The lead time in manufacturing is the length of the production process, from start to finish. This time frame accounts for various phases, starting with a product order and following it from processing and production to shipping and delivery. As for how to calculate lead time, three main factors affect lead […]

Tags: Lead Times

Choosing the Right Automation Equipment

Leave a CommentIn the past, adding workers to resolve operational problems was a viable solution for many businesses, but this isn’t the case today. Instead, automation is the solution to lengthening shifts and recent struggles to find employees. With automation, companies can increase efficiency and productivity without increasing labor expenses. When choosing the right industrial automation equipment […]

How Industrial Automation Equipment is Helping to Bring Back Manufacturing to America

Leave a CommentIndustrial Automation is Powering and Innovating American Manufacturing Advances in automation technology improve manufacturing techniques and power product innovation by enhancing how components are produced. Due to technology such as adaptive robotics, machine learning, and others, manufacturing processes are currently more refined and inexpensive than in the past. Investing in these technologies has enabled smaller […]

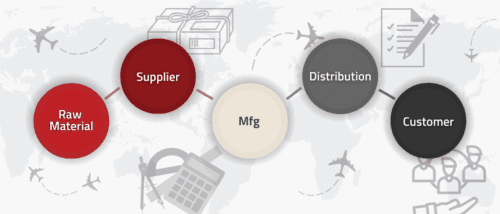

What Is Supply Chain Resilience?

1 CommentThe COVID-19 pandemic was an eye-opener for many businesses, revealing their supply chains’ limits and vulnerabilities. Supply chain resilience is the capacity of a supply chain to adapt to unforeseen events. Companies with resilient supply chains not only have the capability to adjust rapidly and continue operations in the face of supply chain challenges, but […]

Why Robotic Cells Are the Future of Manufacturing

1 CommentA robotic cell, also known as a robotized cell, is a group of machines set within an automatic work cell. The primary purpose of robotic cells is to maximize, accelerate, and simplify the production process so that it attains a high level of repeatability and quality. Unlike human workers or traditional machines, robotic cells are […]