Continuous increases in the consumer demand for household appliances have driven appliance manufacturers to look for ways to boost their supply without compromising product quality or raising production costs. As a solution, original equipment manufacturers (OEMs) have incorporated industrial automation equipment in their operations. Automation technology has improved productivity and flexibility while lowering labor costs because there is little human involvement. Automation equipment can perform stamping, painting, machining, assembling, and testing functions. Manufacturers use automation to produce small appliances such as toasters, blenders, irons, vacuums, fans, and humidifiers/dehumidifiers as well as larger appliances like washers, stoves, and refrigerators. AMD uses bending or assembly manufacturing processes to generate parts for such applications.

Even on manual assembly stations where making the process automatic is not a viable solution because of economic constraints, technology can be used to verify and validate every step in the assembly process to guarantee the compliance with the quality specifications of the final product.

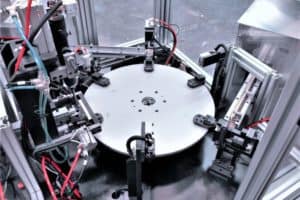

Components for household appliances are often injection-molded, which is an ideal opportunity to incorporate robotic technology. In a workcell for plastic injection molding, robots can effectively grasp a sprue and runner assembly to take a finished component out of a mold. Robots are ideal for this rather than dumping parts from a mold because those components can be very delicate. Automated robotic workcells can handle the production of a wide range of appliance components, including fluid pumps, electrical power systems, electronic control modules, lighting, and tubing systems.