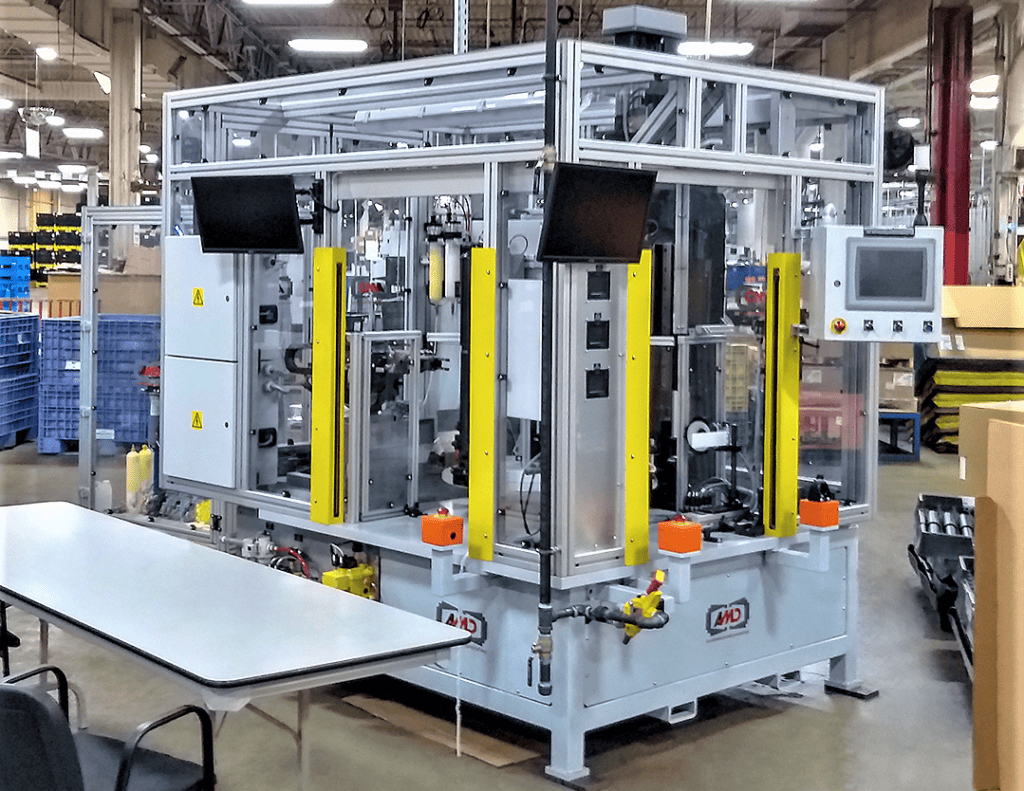

At AMD, we design and build custom machinery to facilitate testing and quality assurance across many industry sectors. Each test system is tailored to the exact requirements and standards established by the customer, ensuring that the equipment will fit perfectly into existing production or testing lines. Our testing framework includes:

- Inspection

- Electrical testing

- Functional testing

- Leak detection

- Measurement

Implementing advanced testing technology guarantees the highest possible quality standards for your production. The number of out-of-spec parts can be dramatically reduced by implementing in-line testing during ongoing production, as well as end-of-line inspections. In-line tests offer earlier identification of defective components. Parts that fail partial examinations and meet a set of defined criteria can be disposed of or repaired.

What are Automated Test Systems?

Comprehensive quality testing is incorporated into most manufacturing operations. While quality assurance can be conducted manually, the process is slow, less accurate and consistent, and subject to the risk of human error.

Automated testing systems perform all necessary tests on a device or product without the need for operator intervention or handling. Automated testing technology quickly and accurately performs measurements and evaluates the test results against predetermined criteria to ensure it was fabricated within acceptable standards and tolerances.

Types of Test Systems Performed by AMD

Here at AMD, our team has developed testing equipment for applications spanning a broad spectrum of industries. Here are some examples of testing technologies we have designed and implemented:

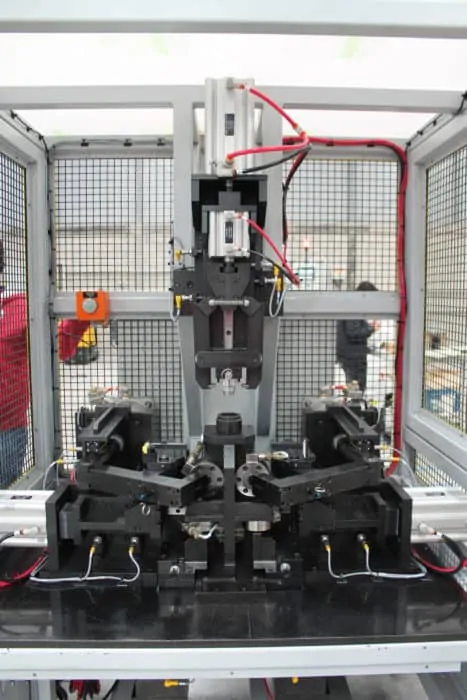

Controlled Force Welding Test

Welds must be tested for penetration and quality after the welding process is complete. A controlled force welding test ensures that the penetration of the weld is acceptable. This type of testing is performed during the assembly process, where components that fail the test are segregated into a red box to set them apart from parts that pass the test.

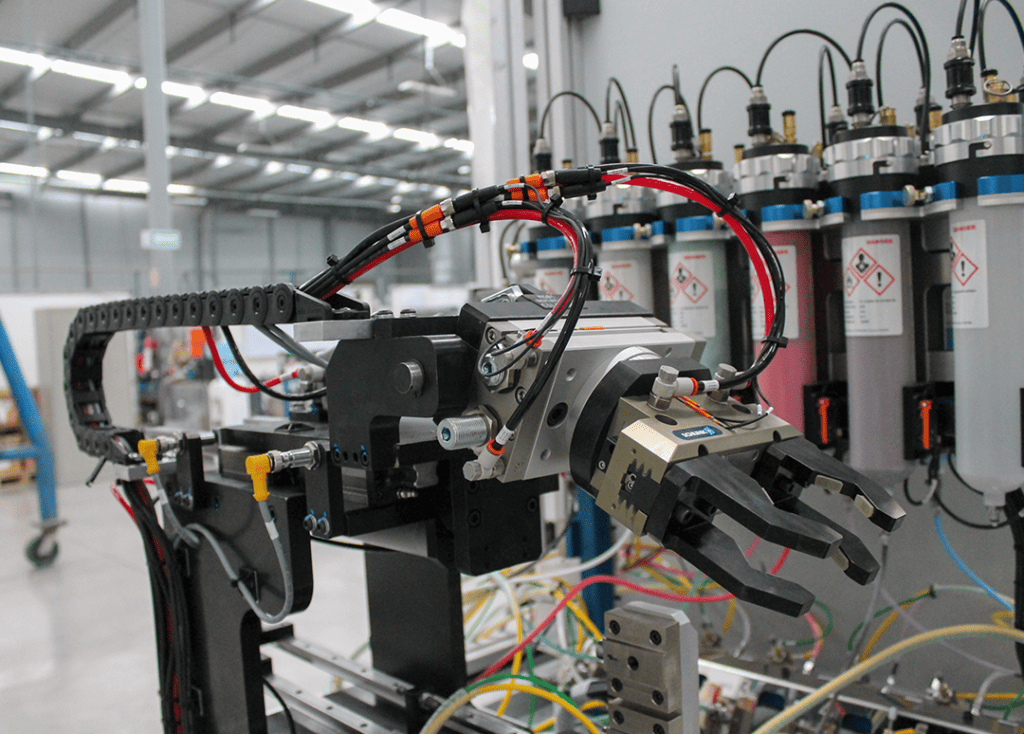

Vision Systems

Process testing or end-of-line testing is a critical step in mass-produced products, such as automotive parts, electronics, or consumer goods. The AMD team can design and implement state-of-the-art vision measurement systems to ensure production line quality. Our advanced testing technology utilizes precision sensors and cameras that inspect every quality aspect of a part. We have created automated test systems and testing stations that detect each component’s presence, verify the right order of all assembly steps, and inspect part dimensions with extremely high accuracy.

Auto Part Noise

A global luxury car company asked us to develop specialized equipment to test their assembled auto parts for noise. The projects involved the detection of tiny noises that are impossible for a human ear to identify reliably in an assembly line environment. Our team developed automated test systems that utilized a variety of testing technologies, including noise-damped chambers, to eliminate ambient noise. Another technique to eliminate ambient air is to detect noise transmitted directly through the metal using high precision accelerometers.

Functional Tests

We developed testing systems to ensure that automatic doors inside the central console opened at precisely the exact same time and distance, or the total stroke and speed for an electric head rest to advance to the extreme positions.

Automatic Weighing Systems

Each phase of fabrication may impact different elements of a product, such as its weight. We have developed automated test systems that recognize the smallest differences in a product during each stage of production to ensure consistent product quality. We incorporate automatic weighing systems along the assembly line that verify that the right amount of each ingredient has been introduced into the assembly or to confirm that the part produced is within acceptable weight limits (this applies for processes like blow molding where the wall thickness can have variations).

Automated Quality Assurance and Production Testing From AMD

At Advanced Manufacturing Development, we design and build turnkey custom-tailored machines for automated assembly lines, fully customizing each system to the needs of the individual customer. Our testing technology guarantees the highest possible quality standards for your production. We offer standalone solutions and integrated test systems that are individually configurable.

To request a quote for your project or learn more about the automated test systems we offer, contact us today.