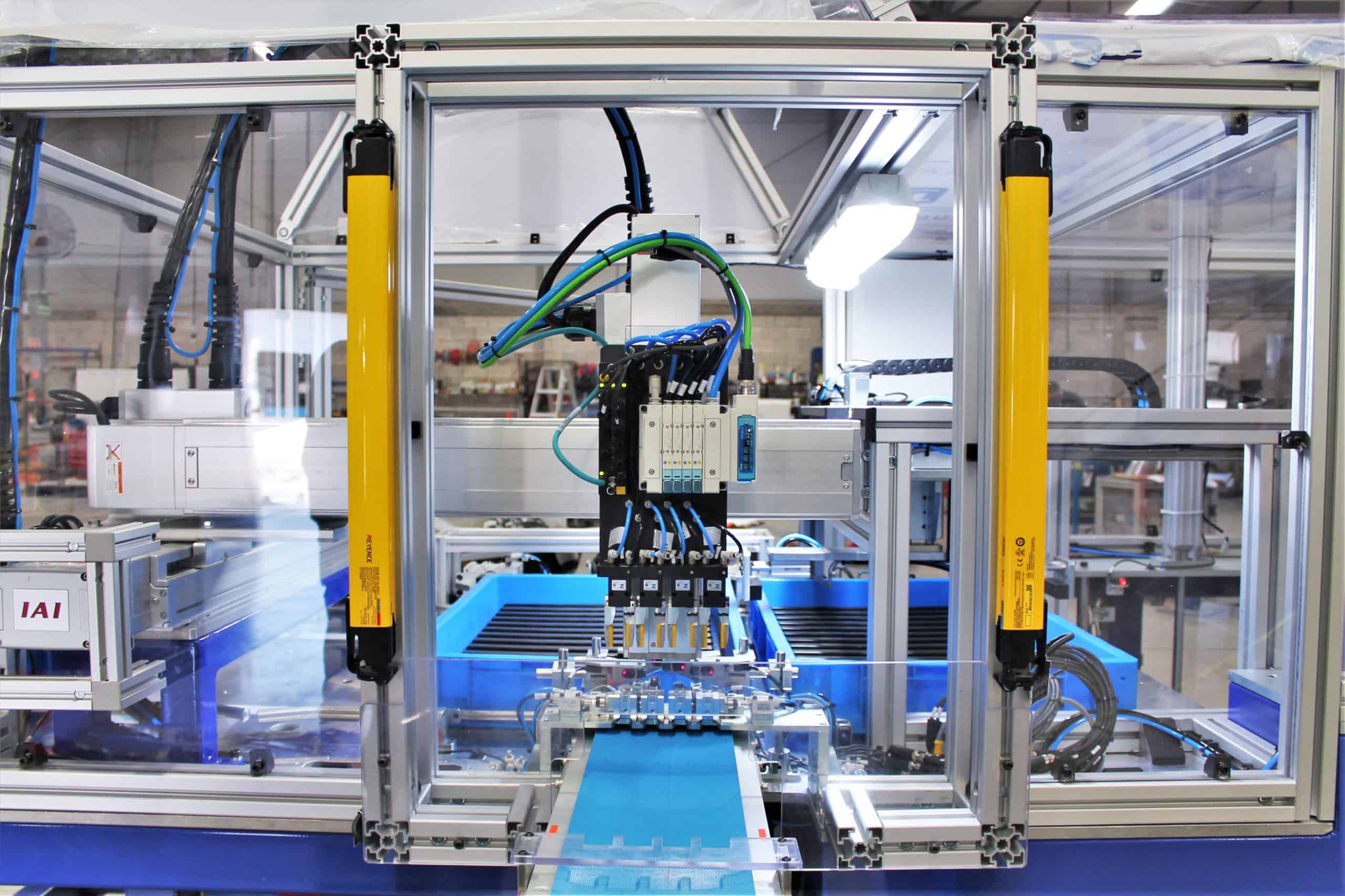

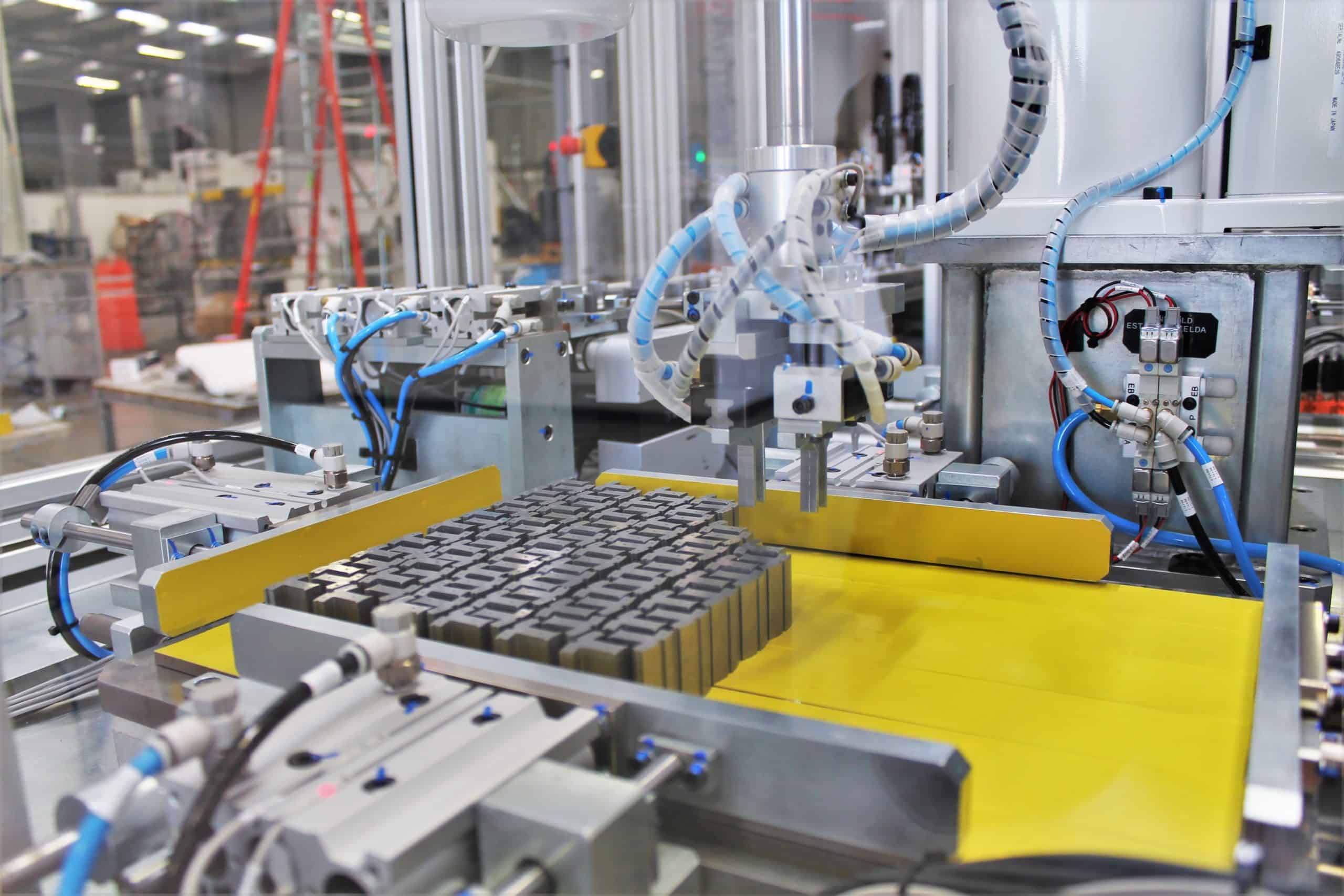

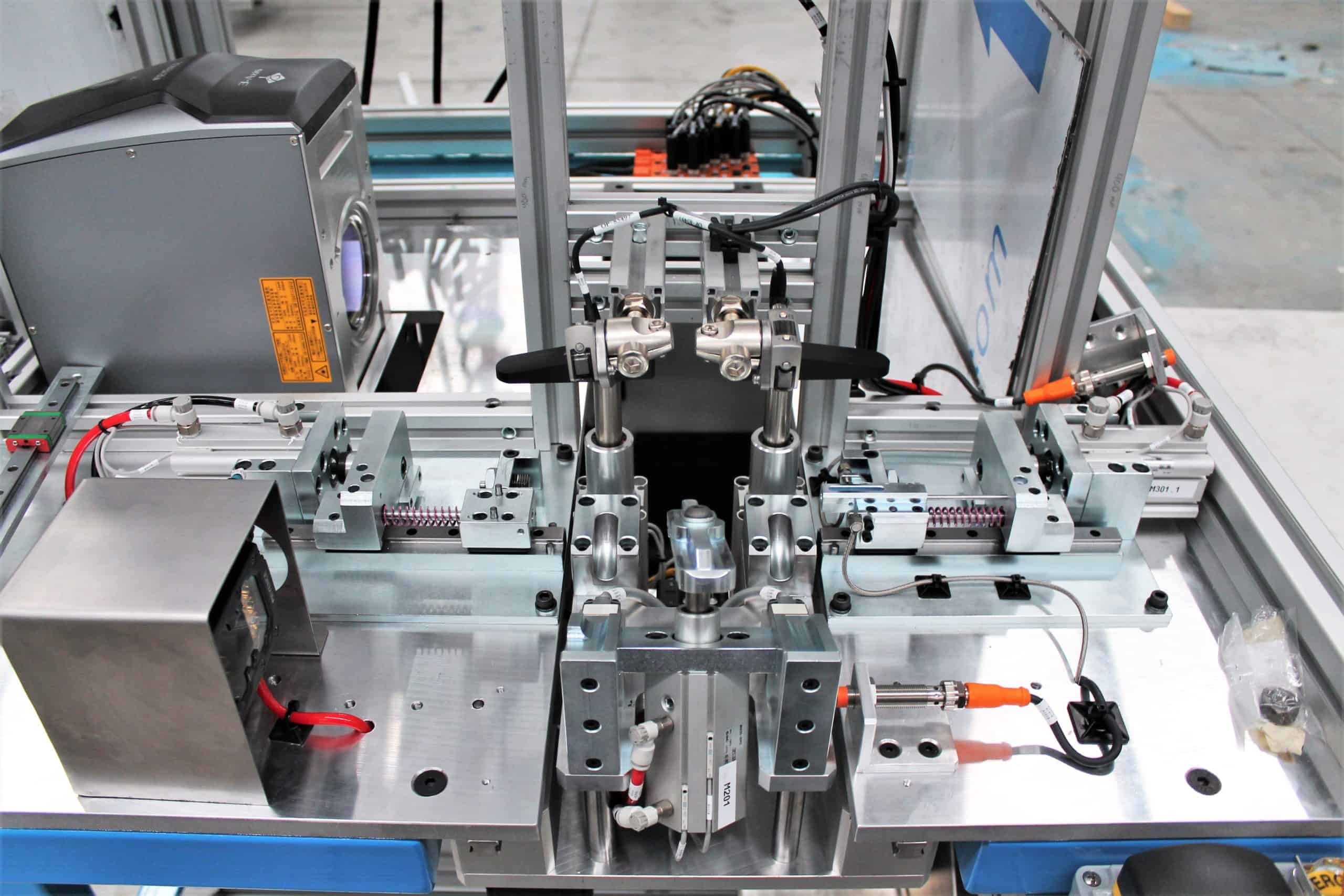

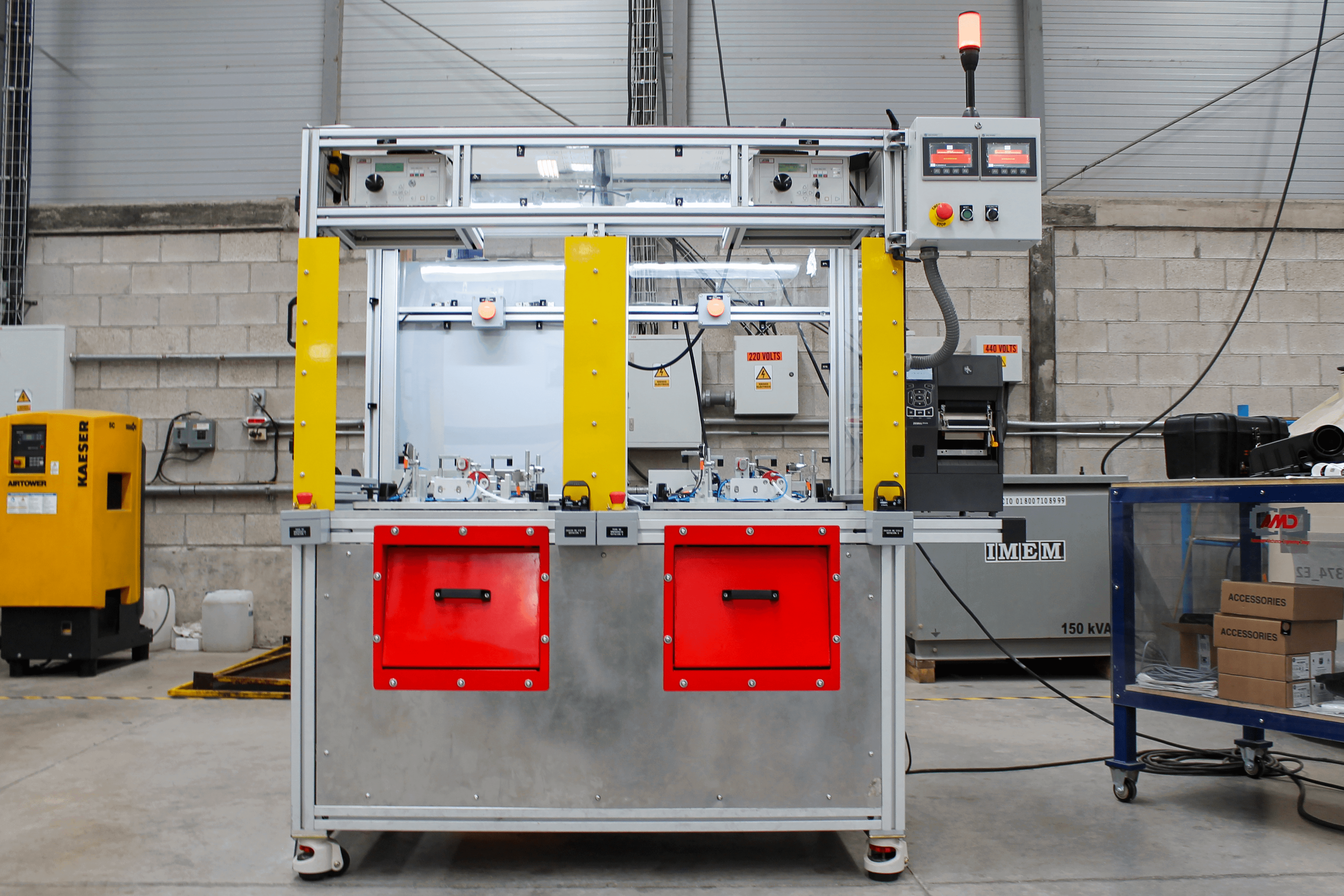

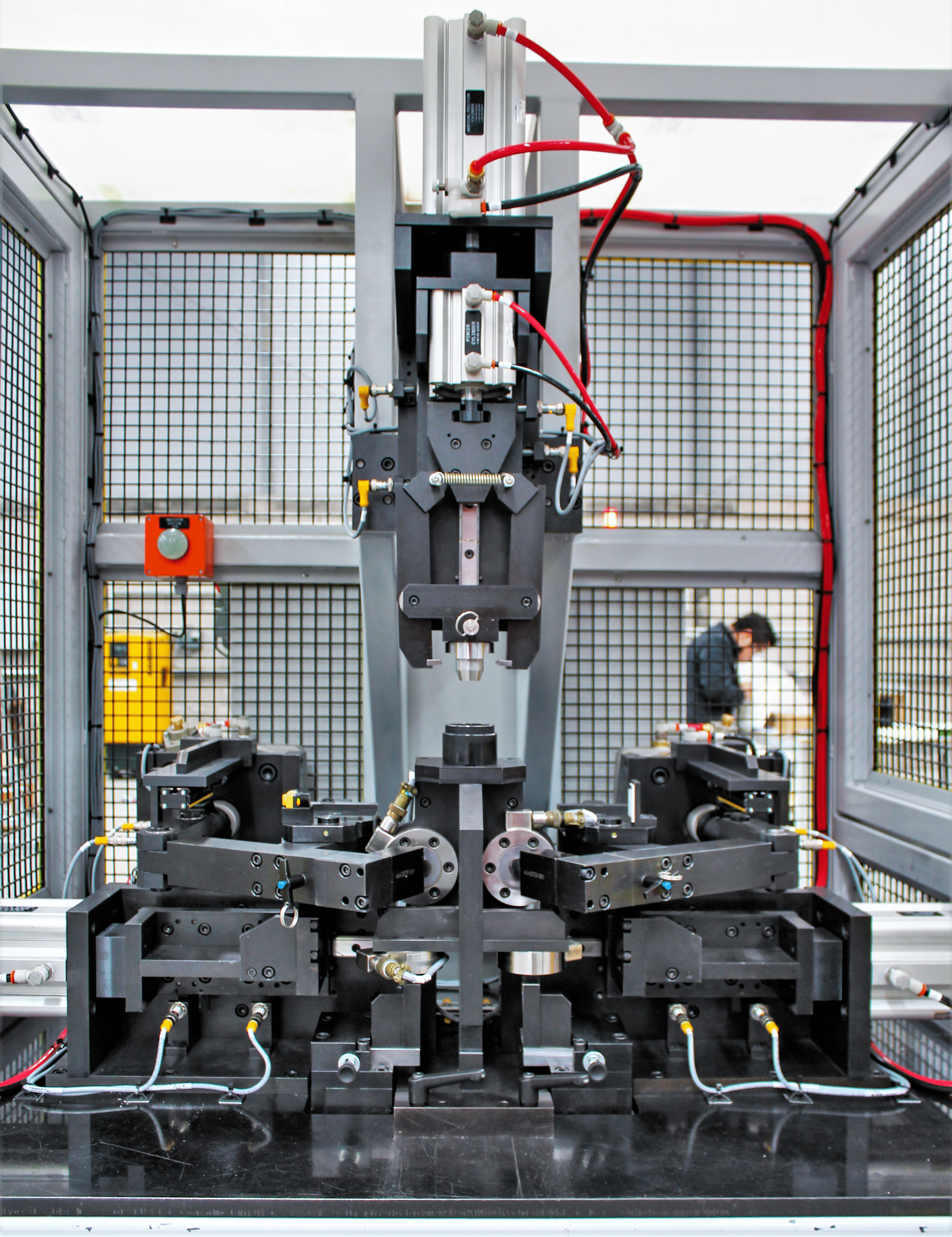

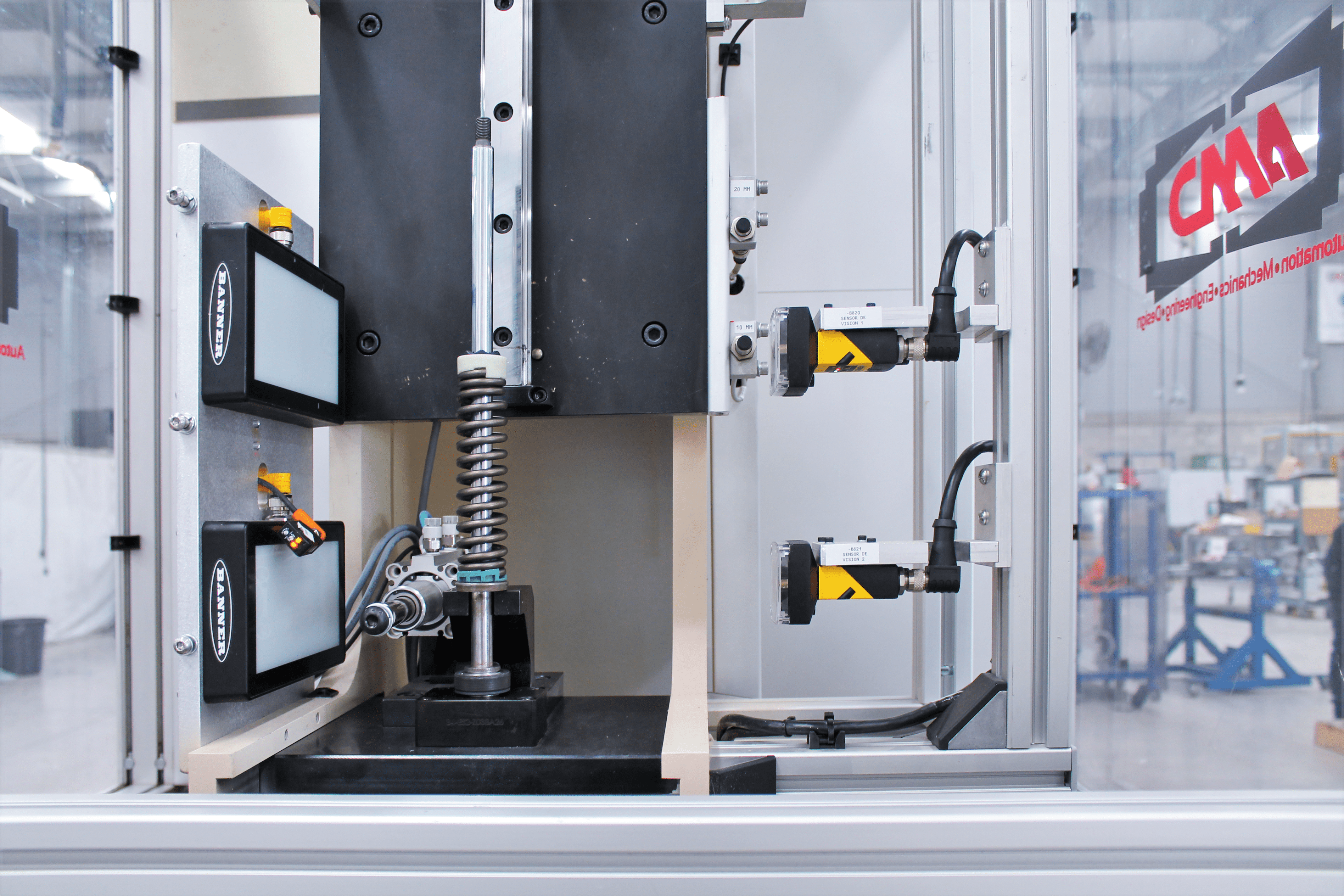

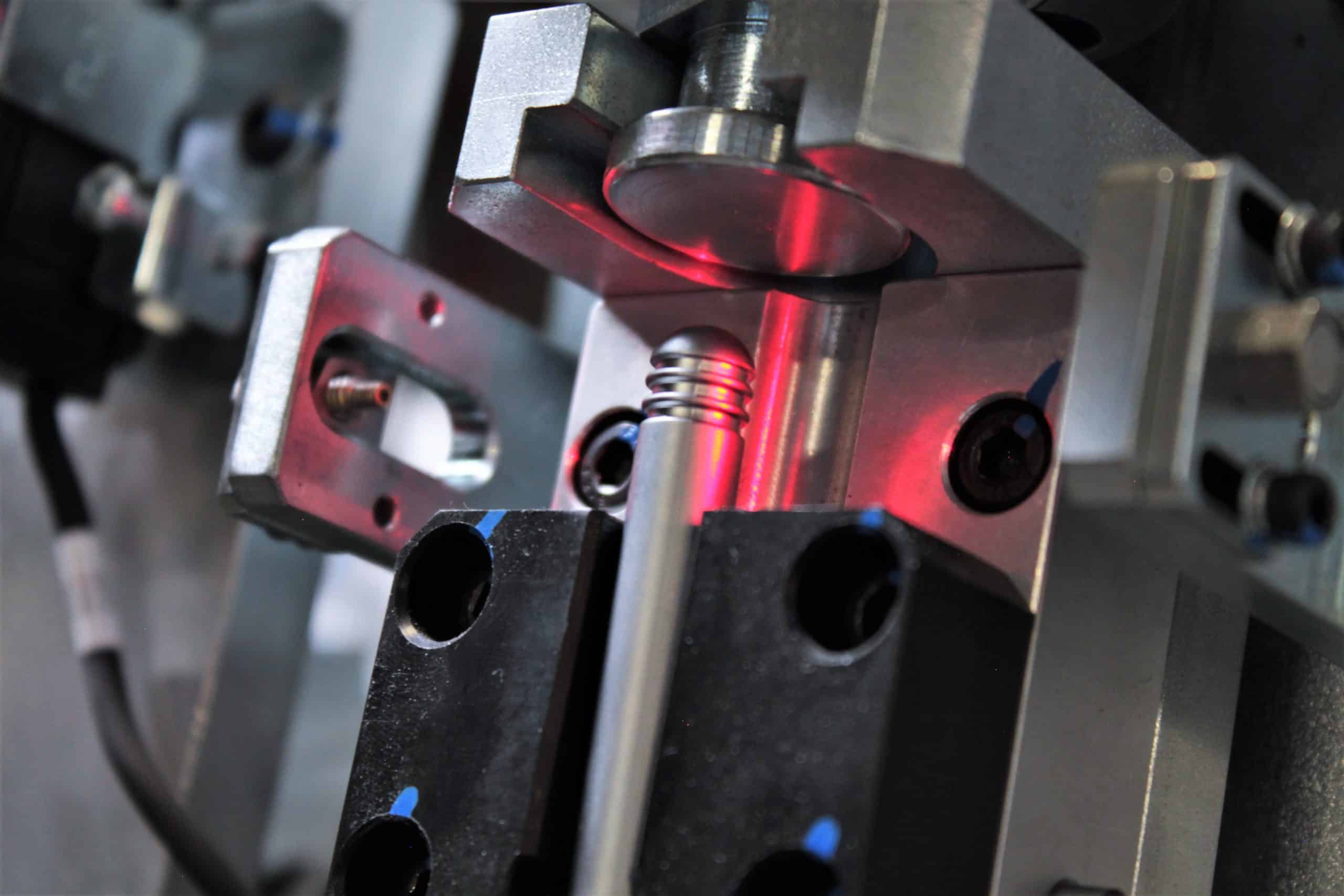

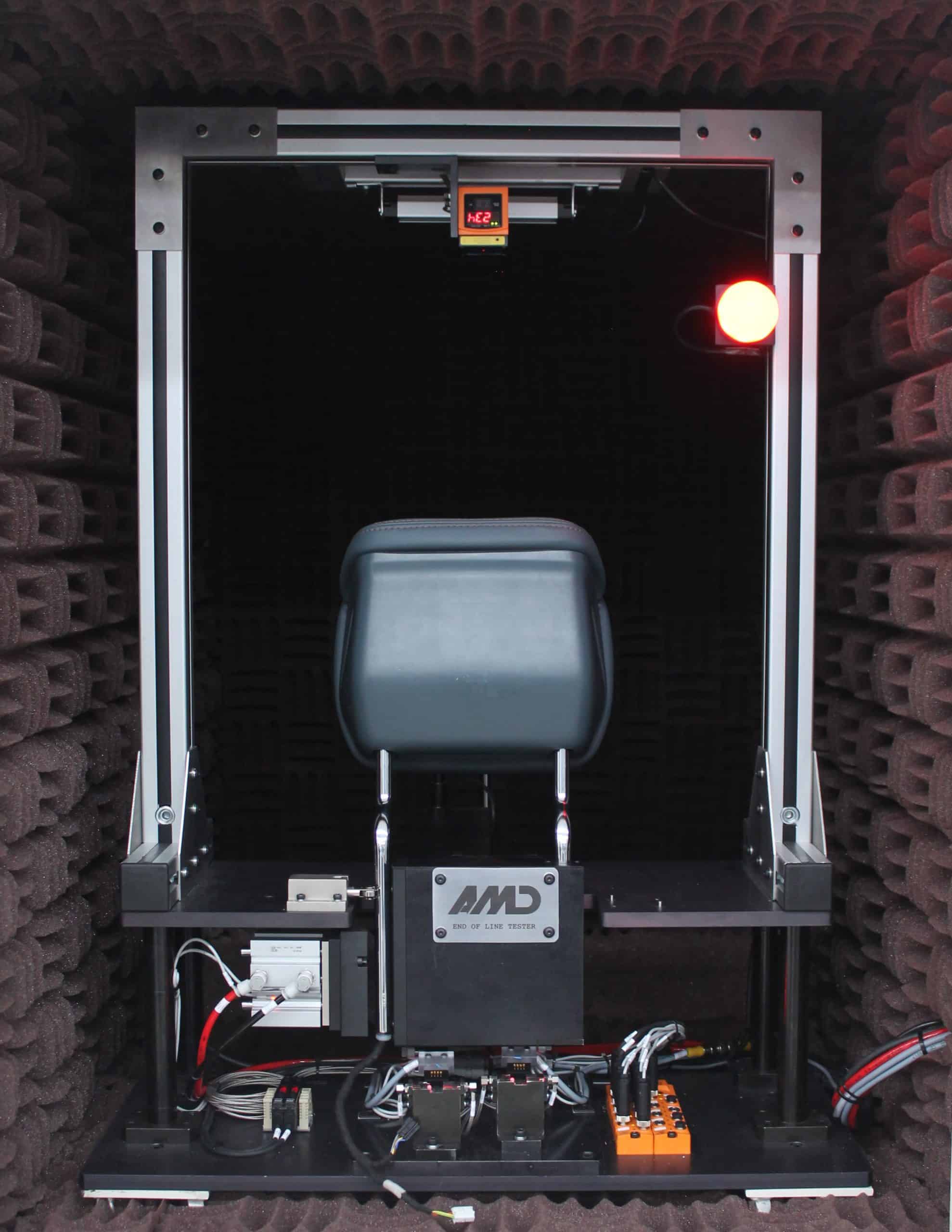

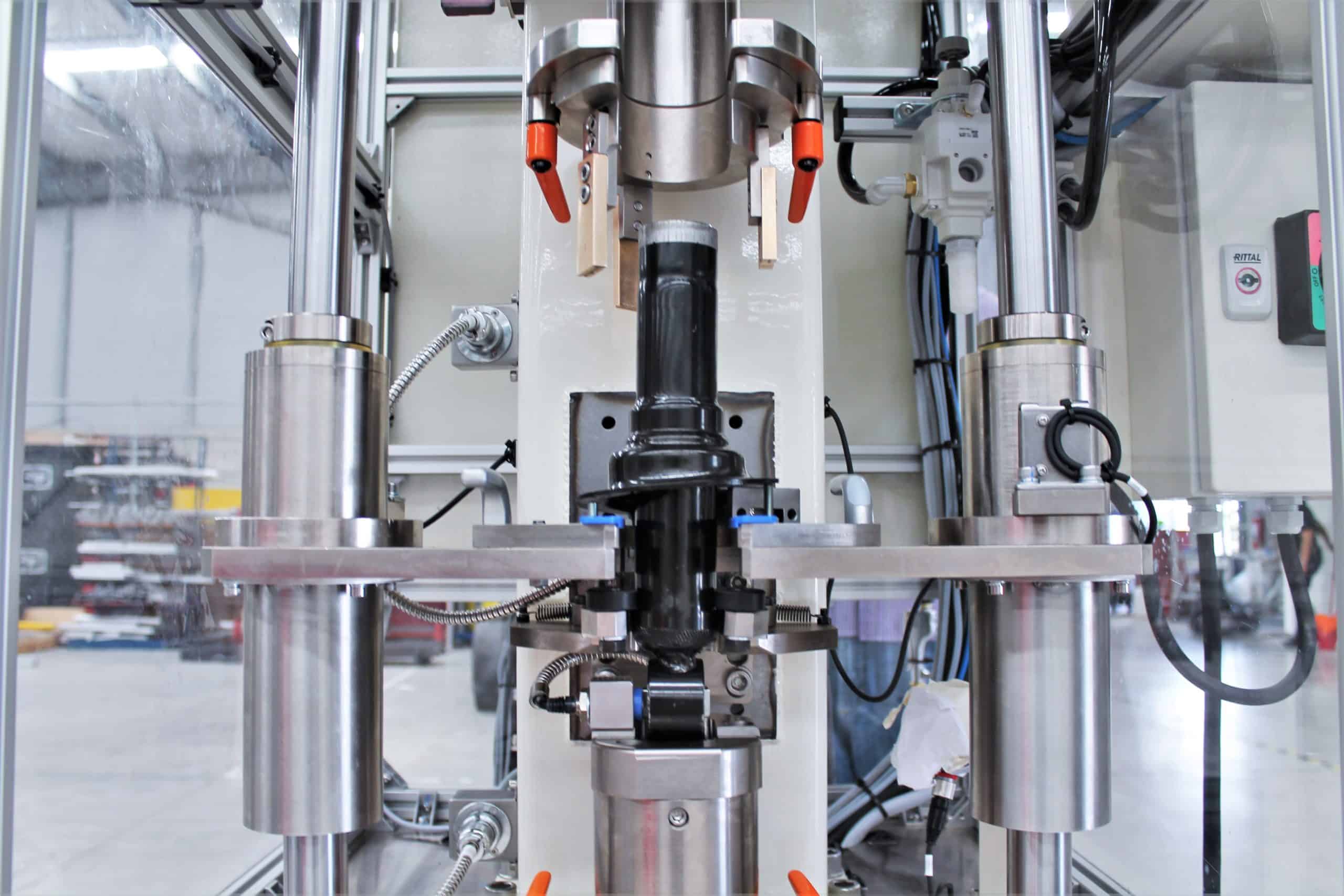

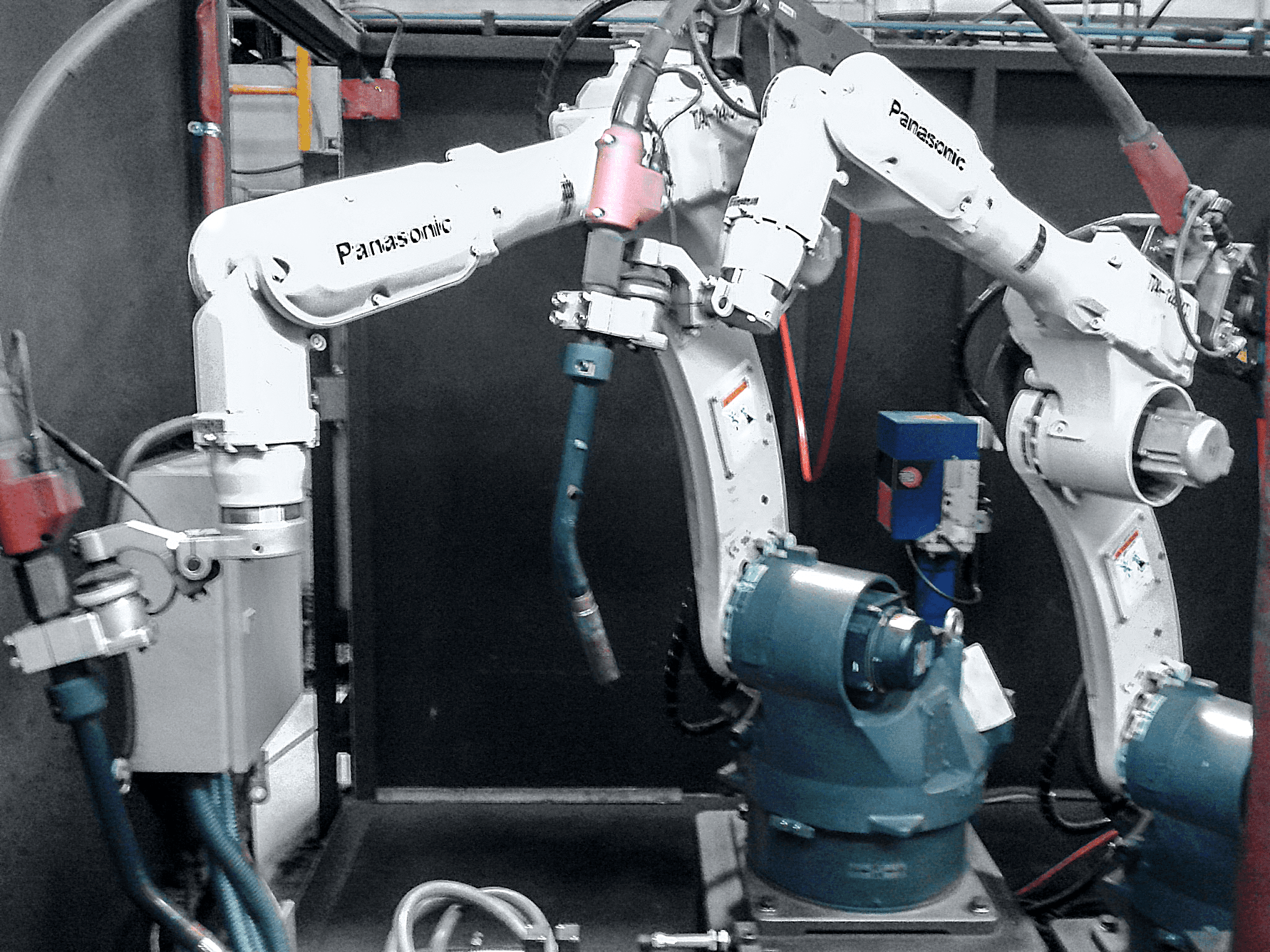

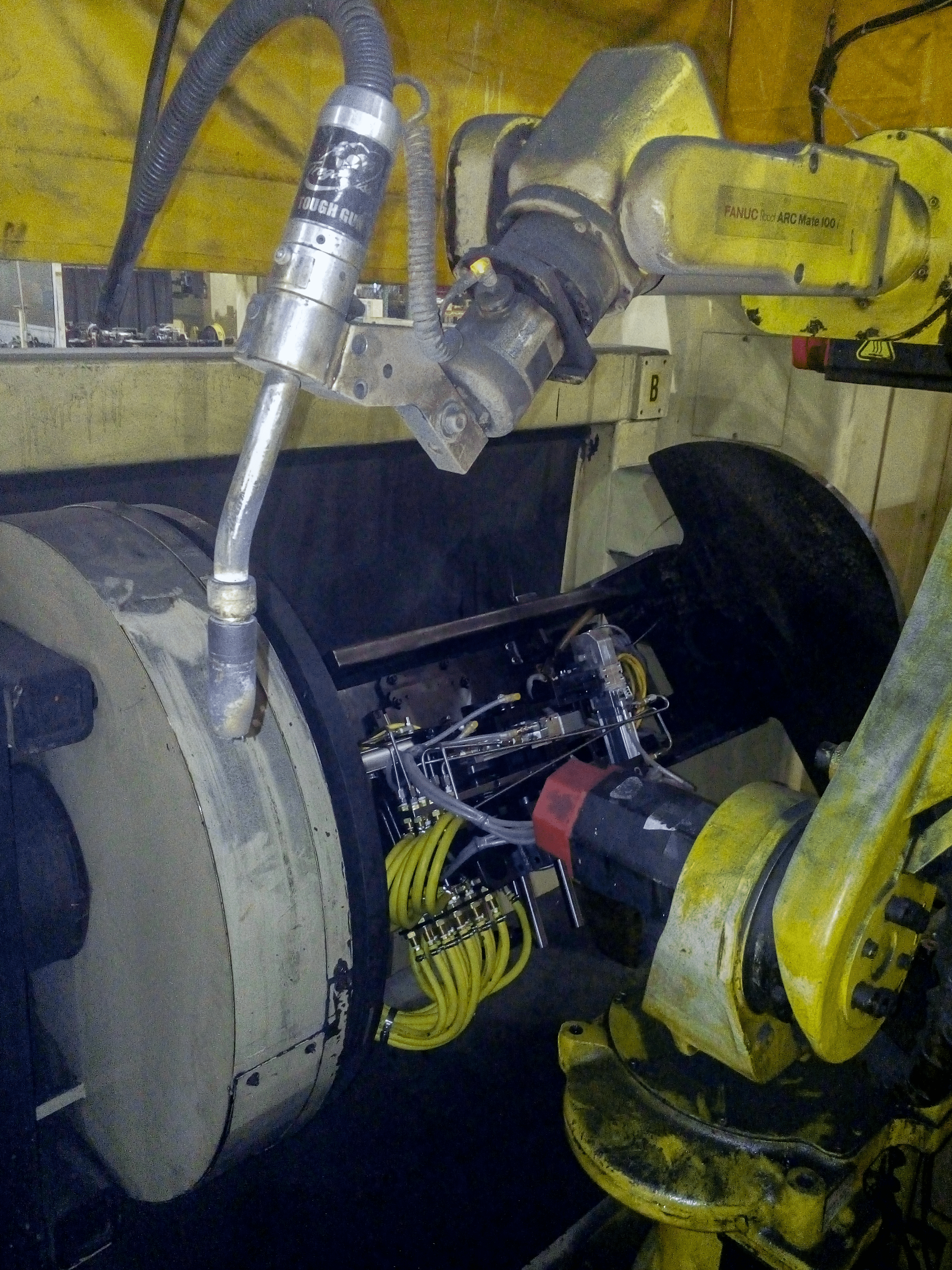

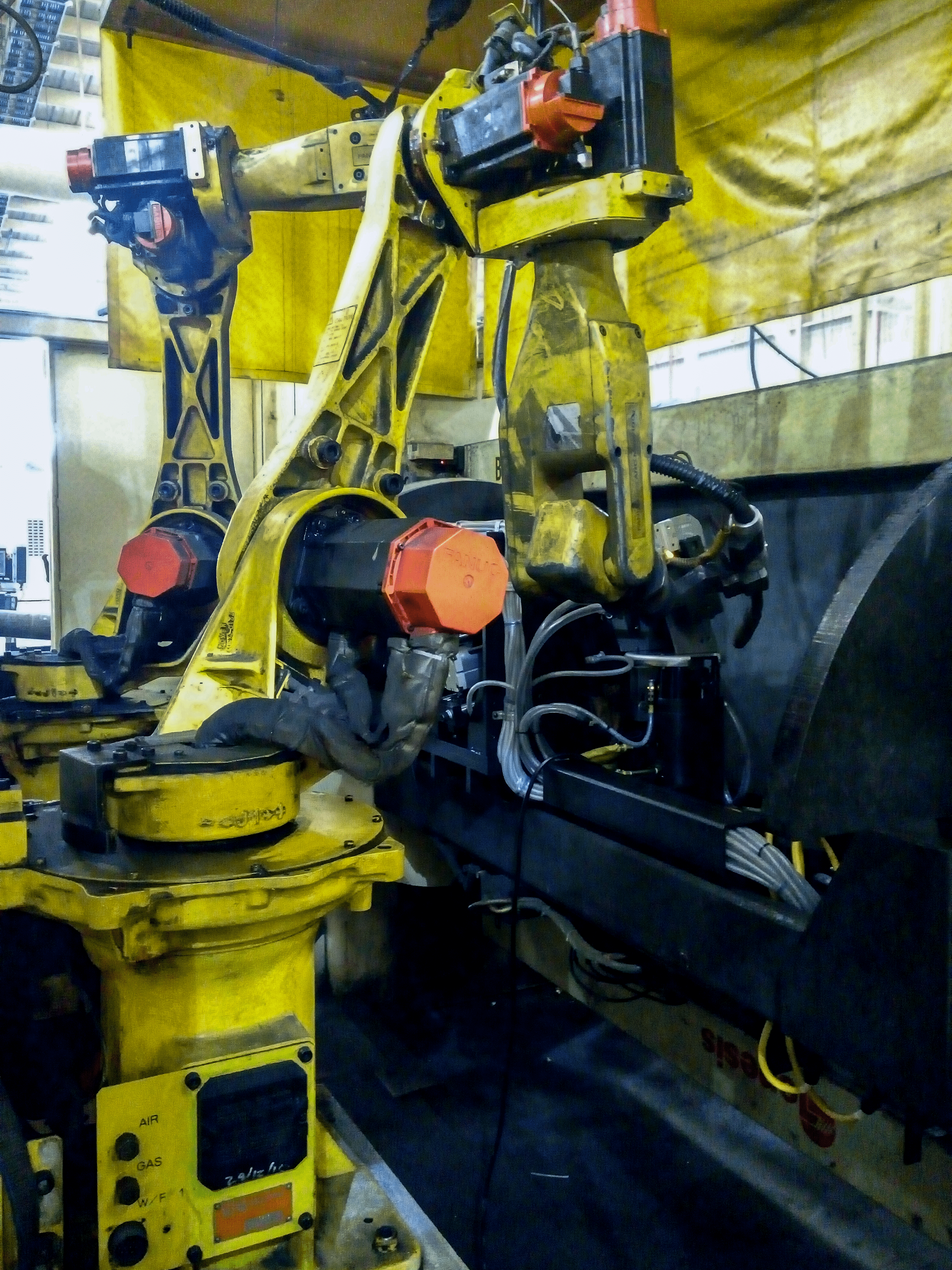

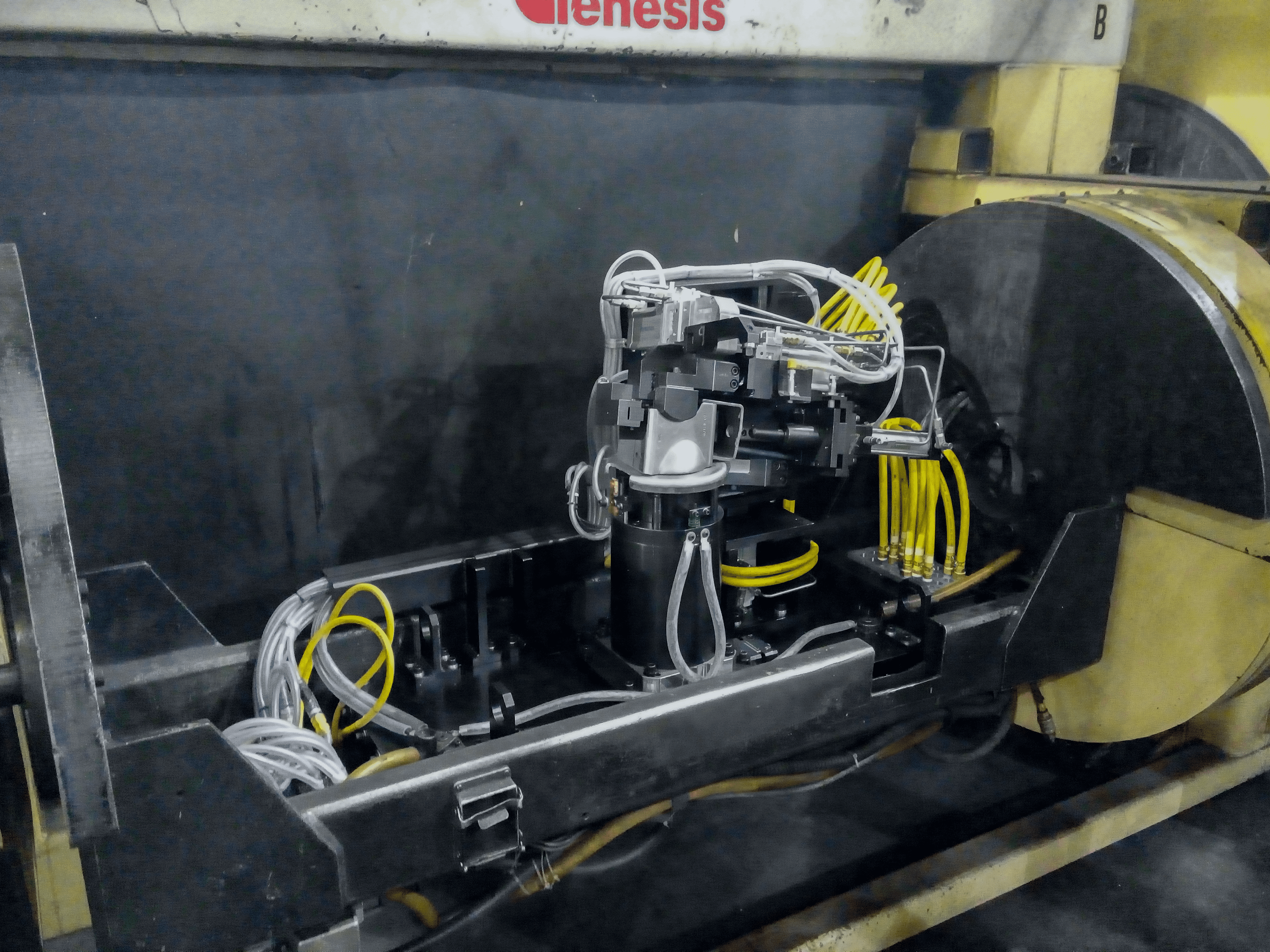

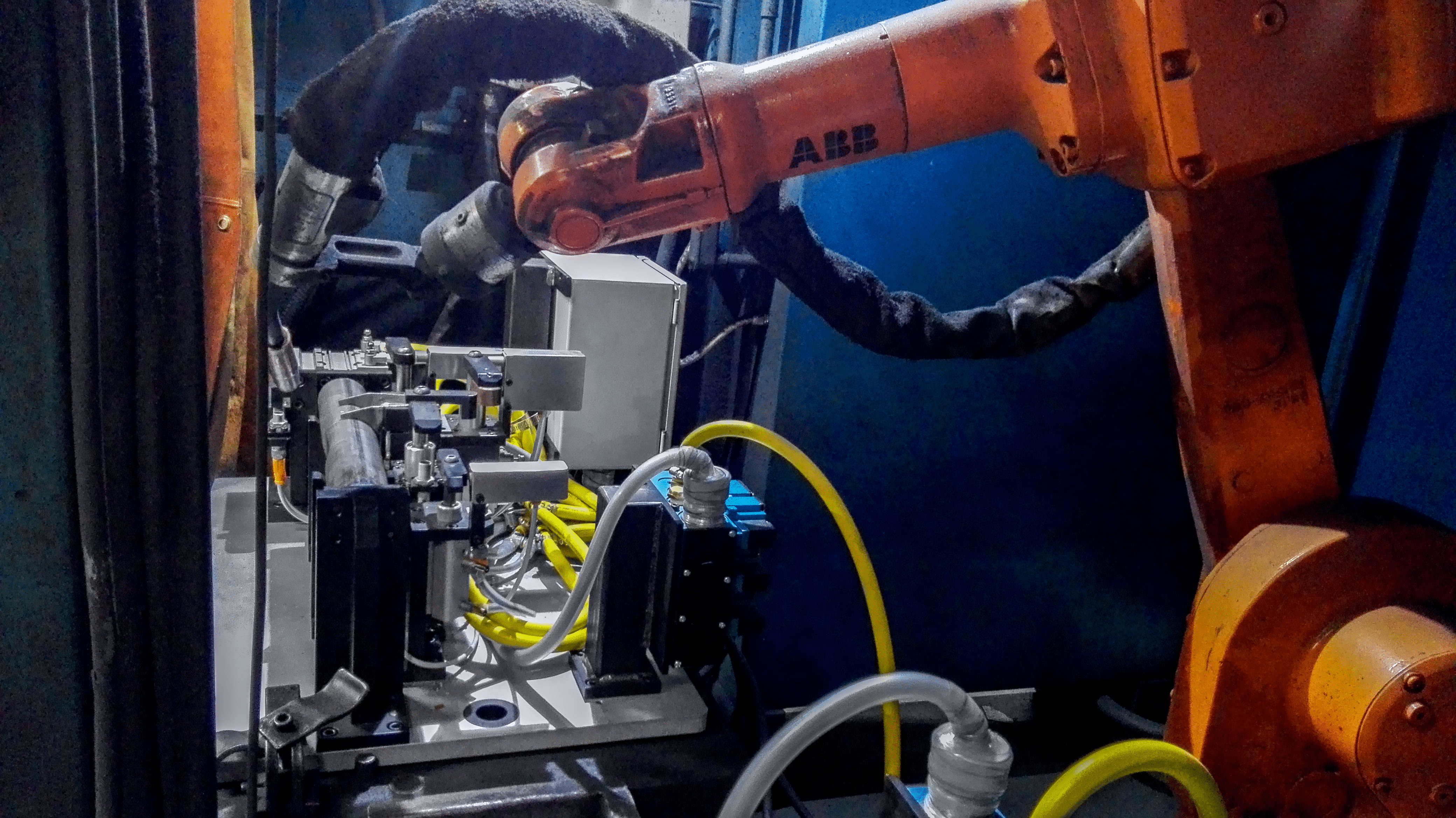

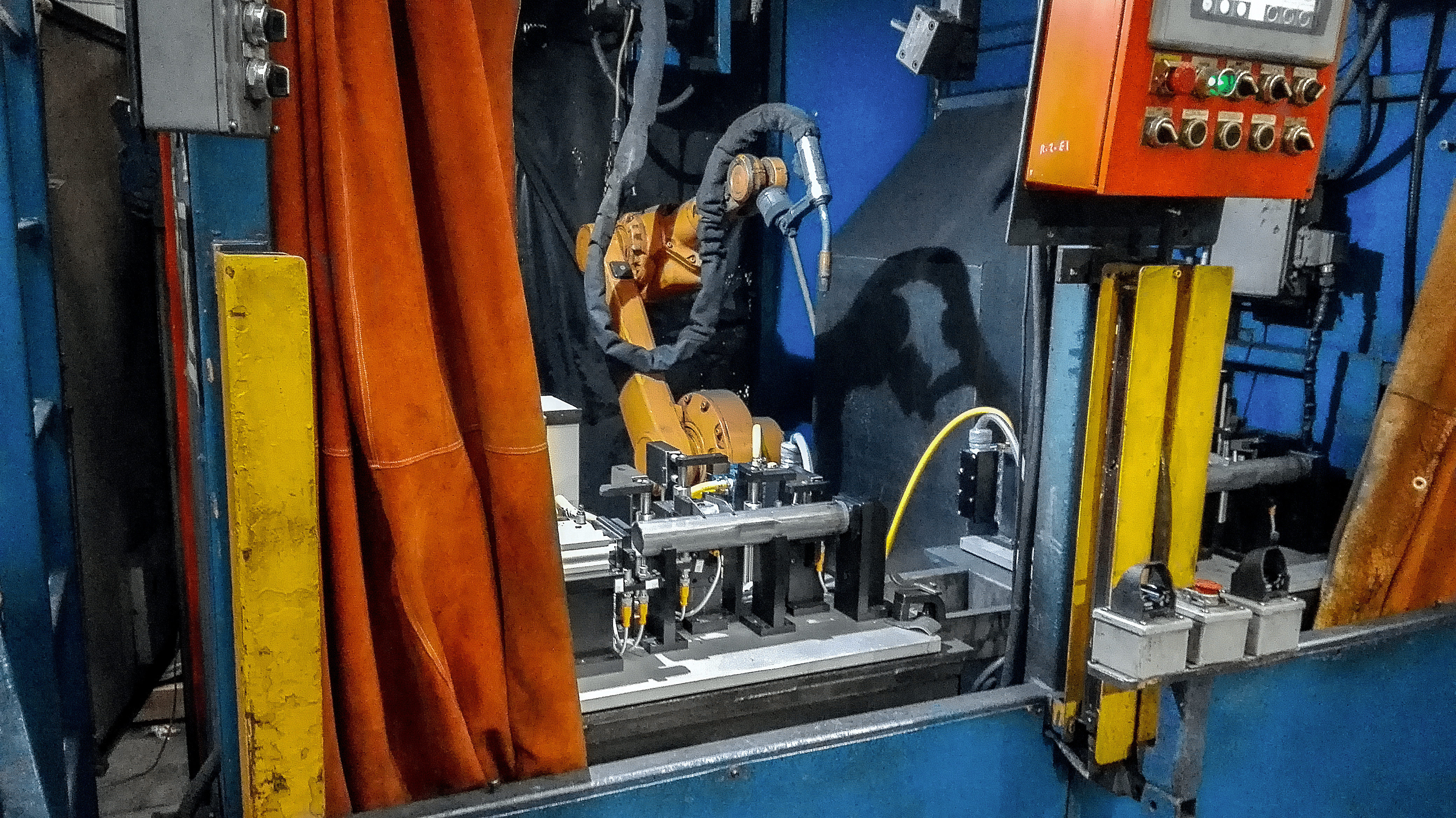

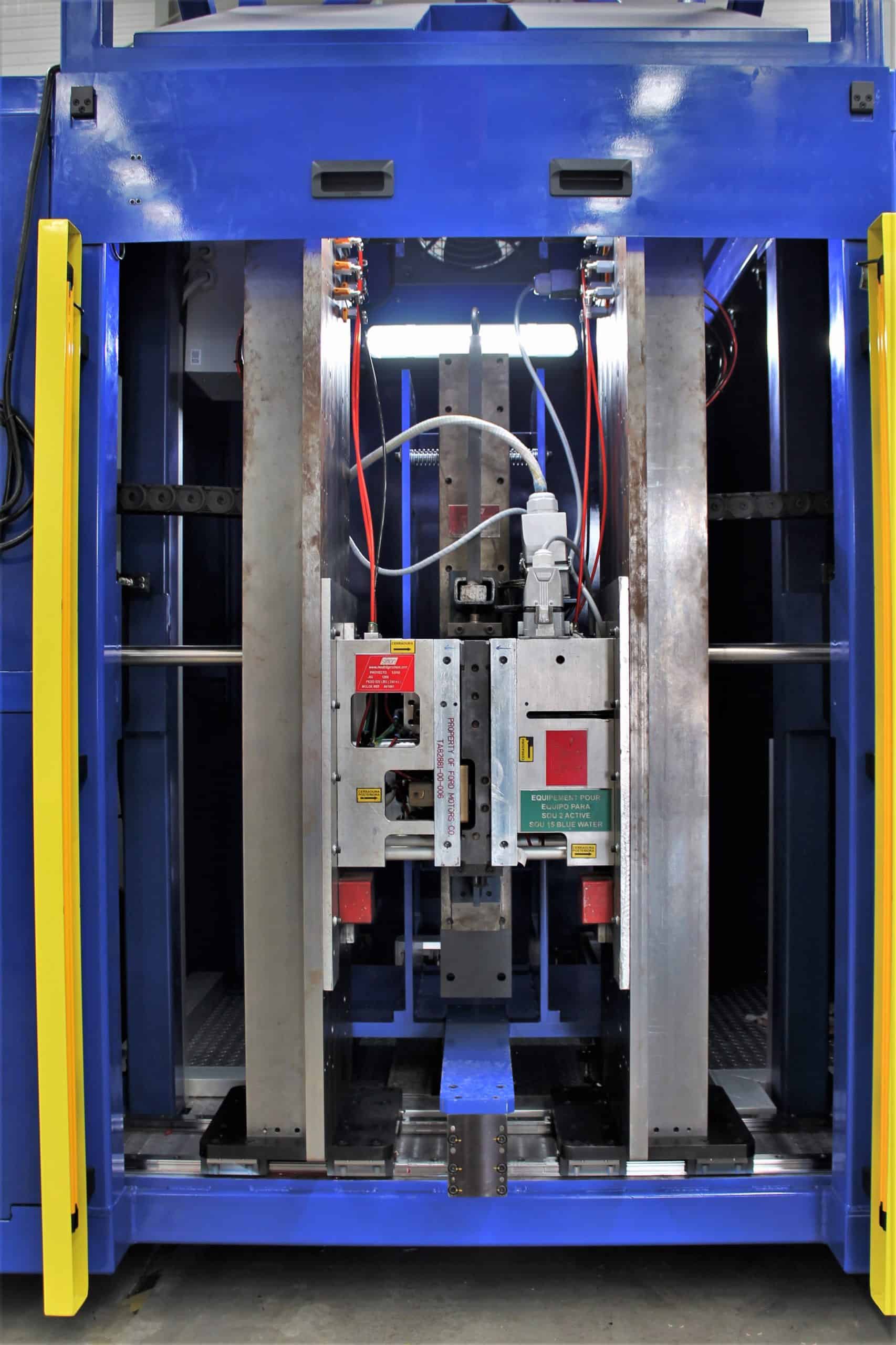

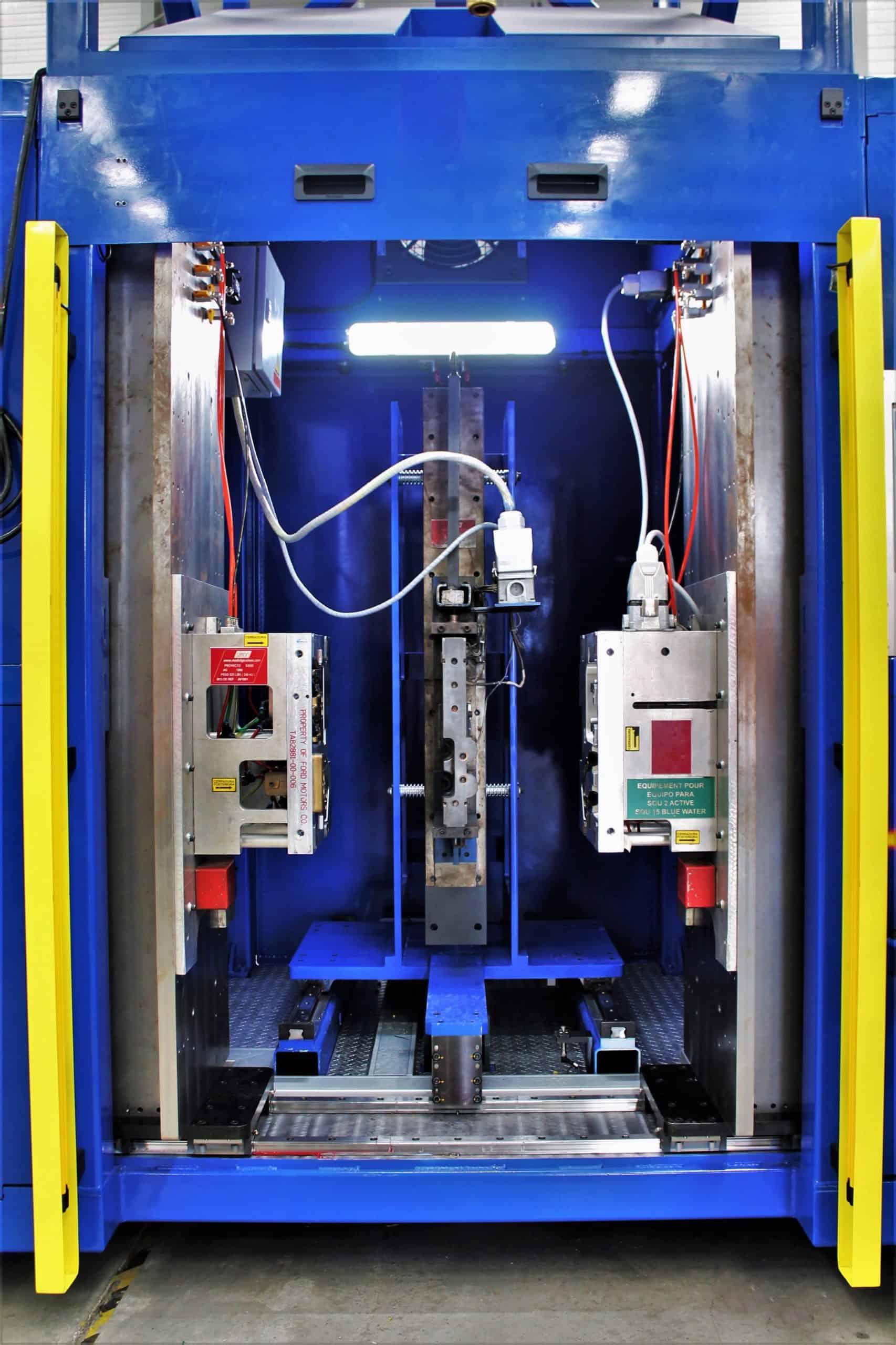

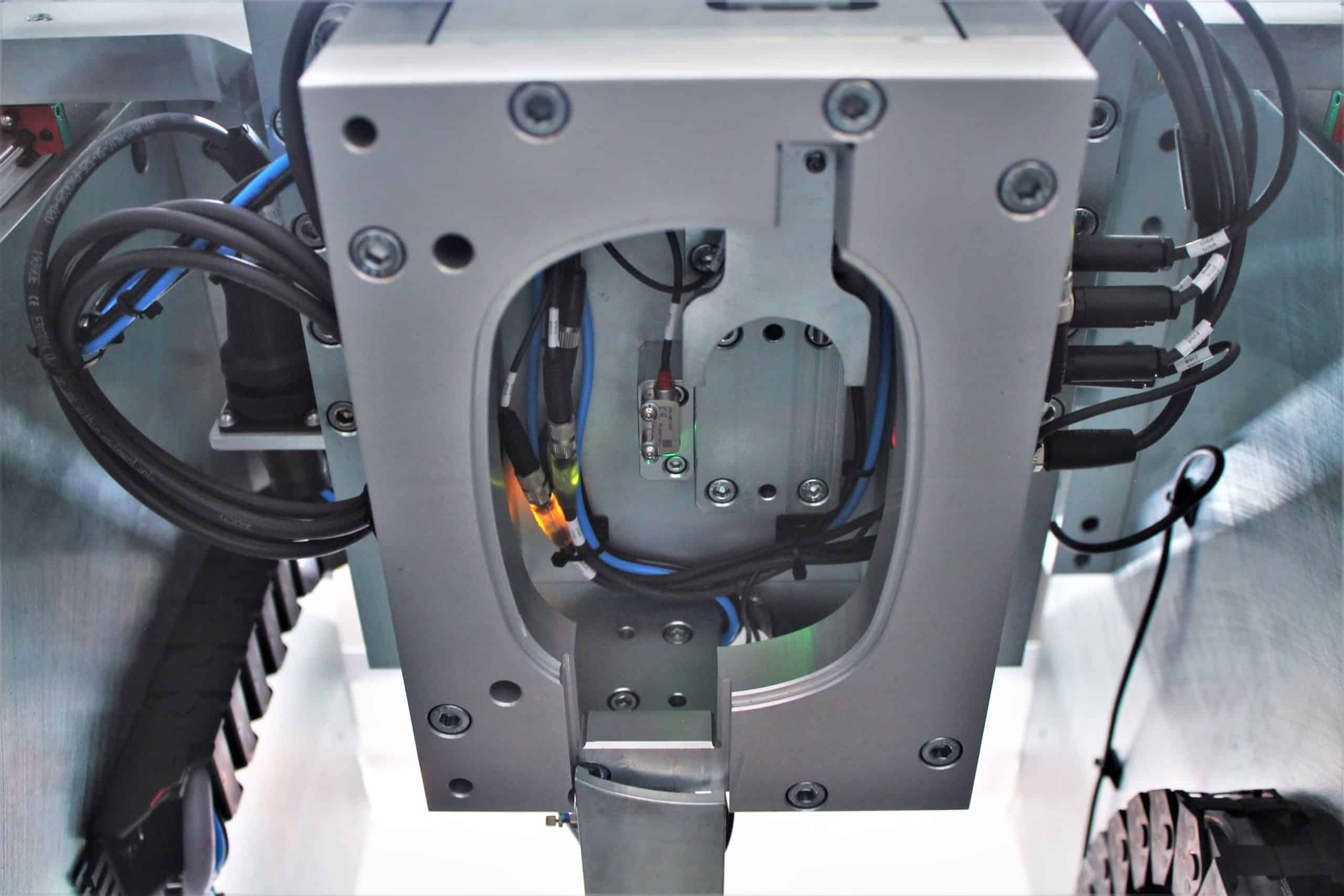

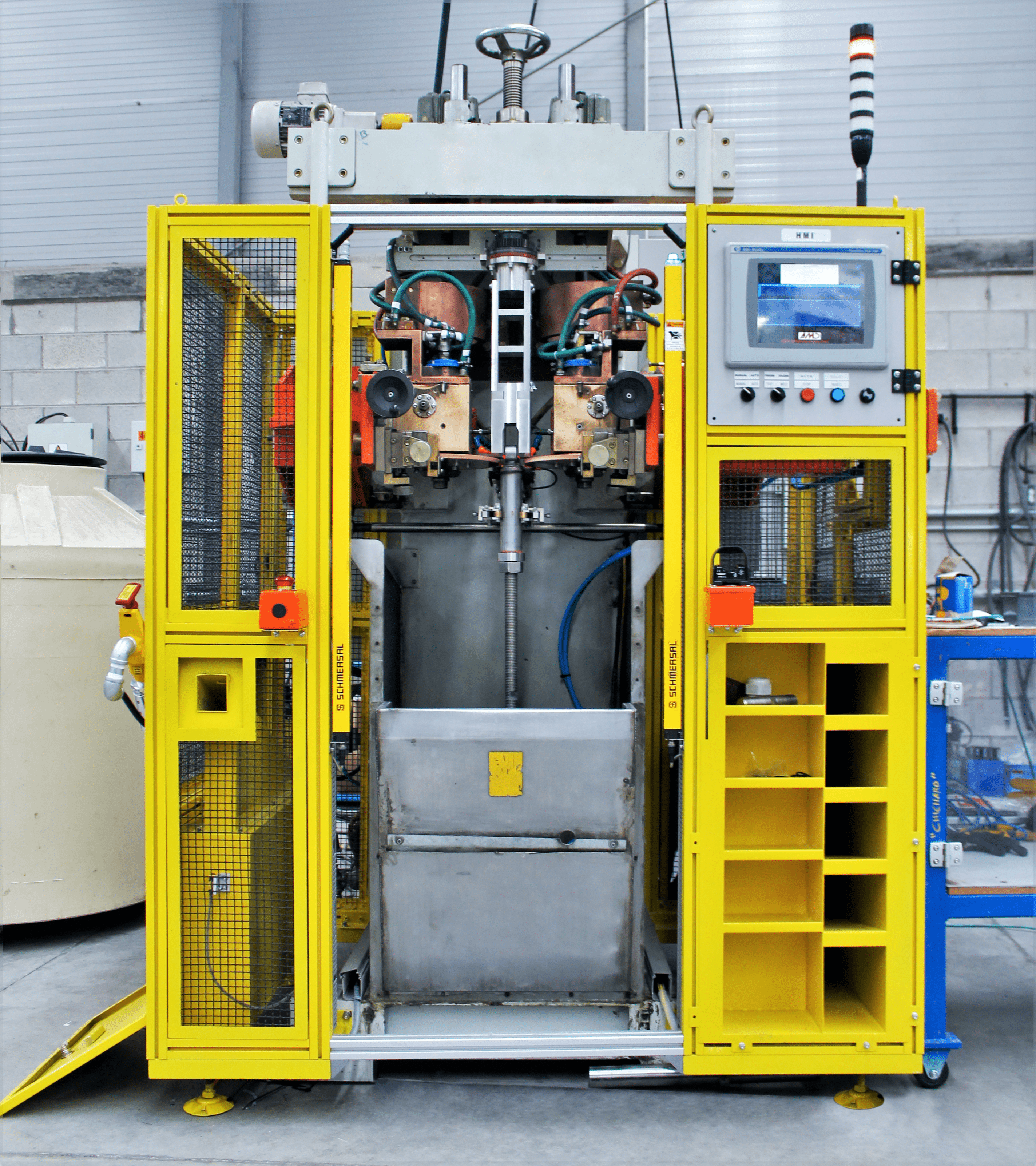

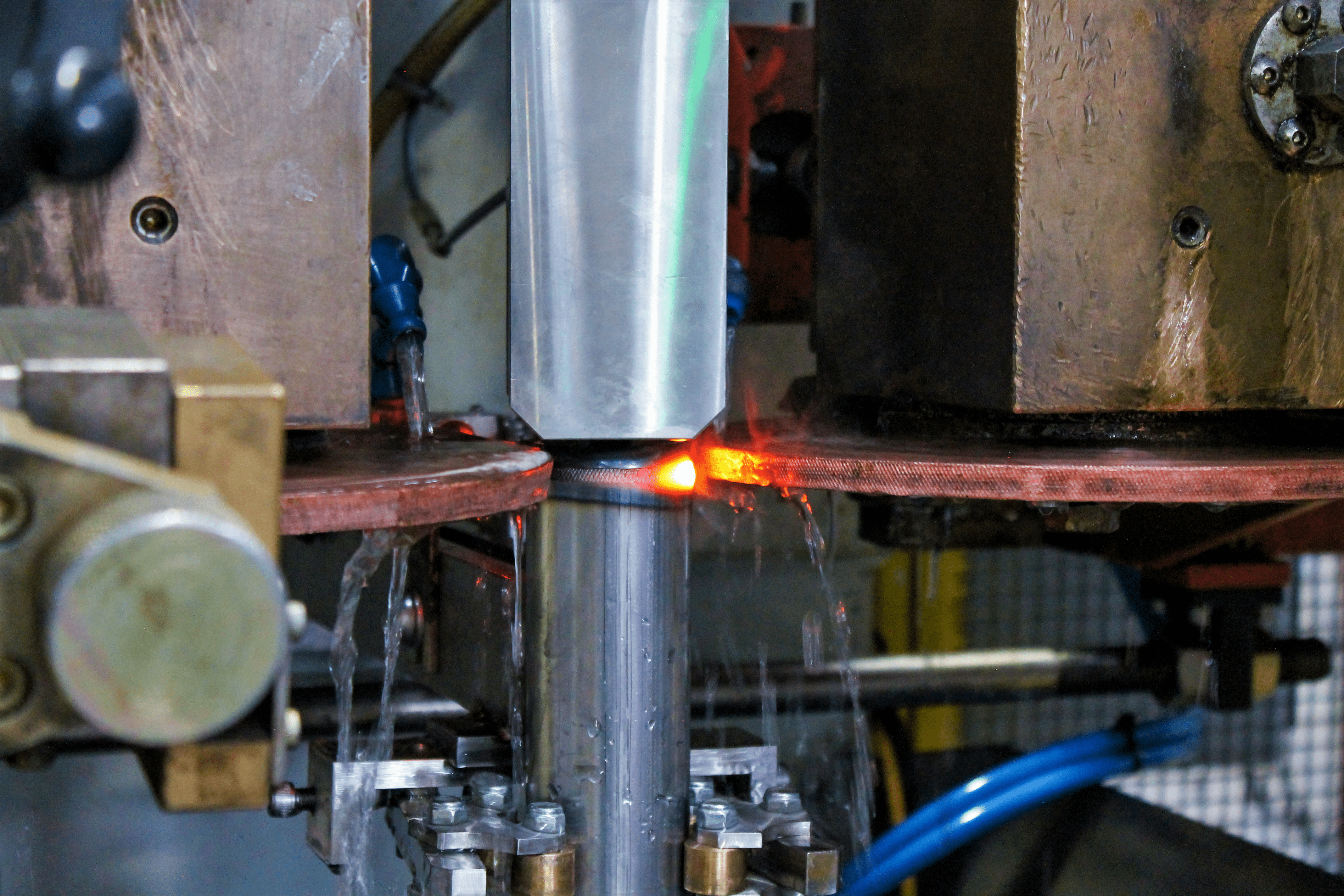

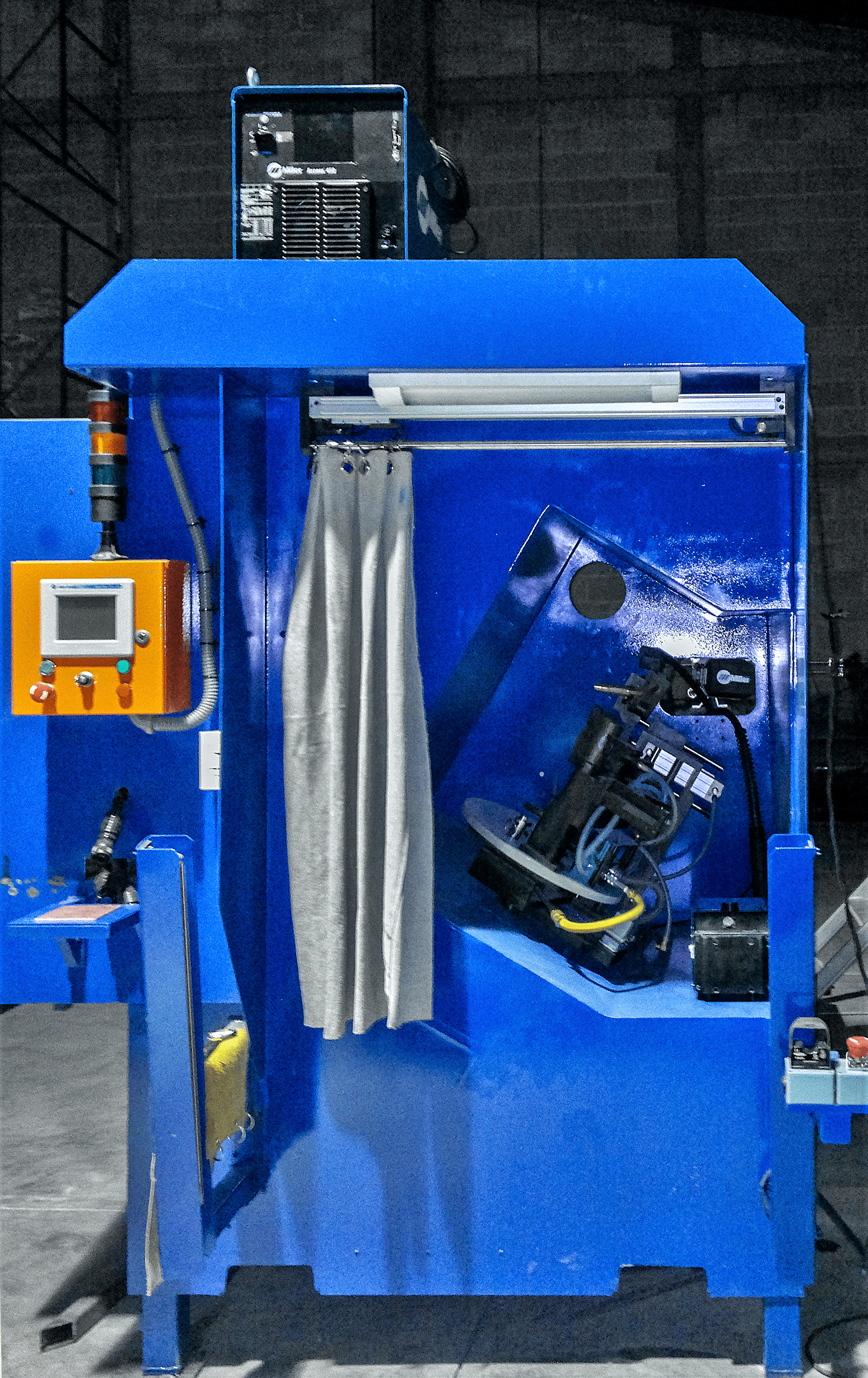

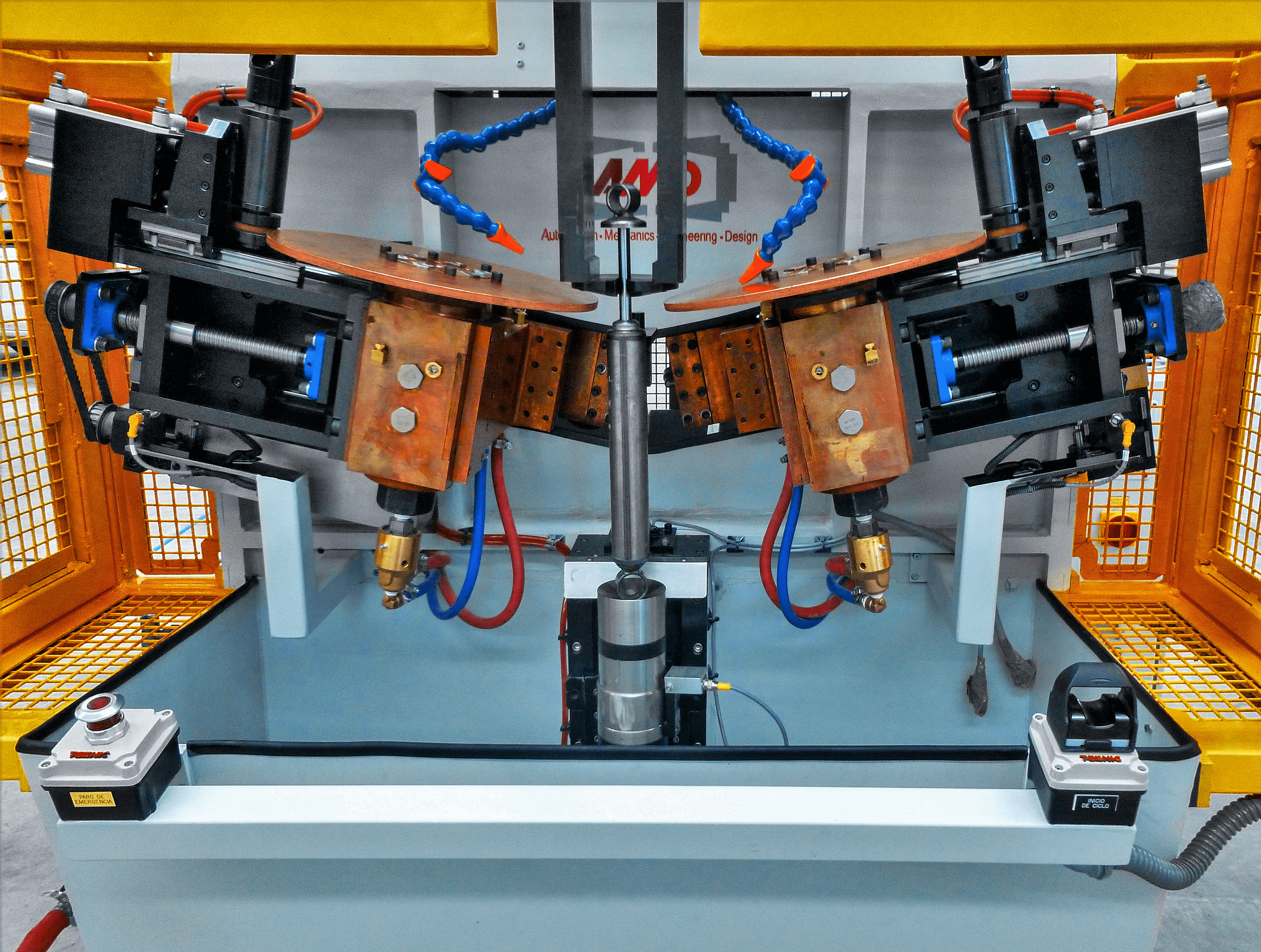

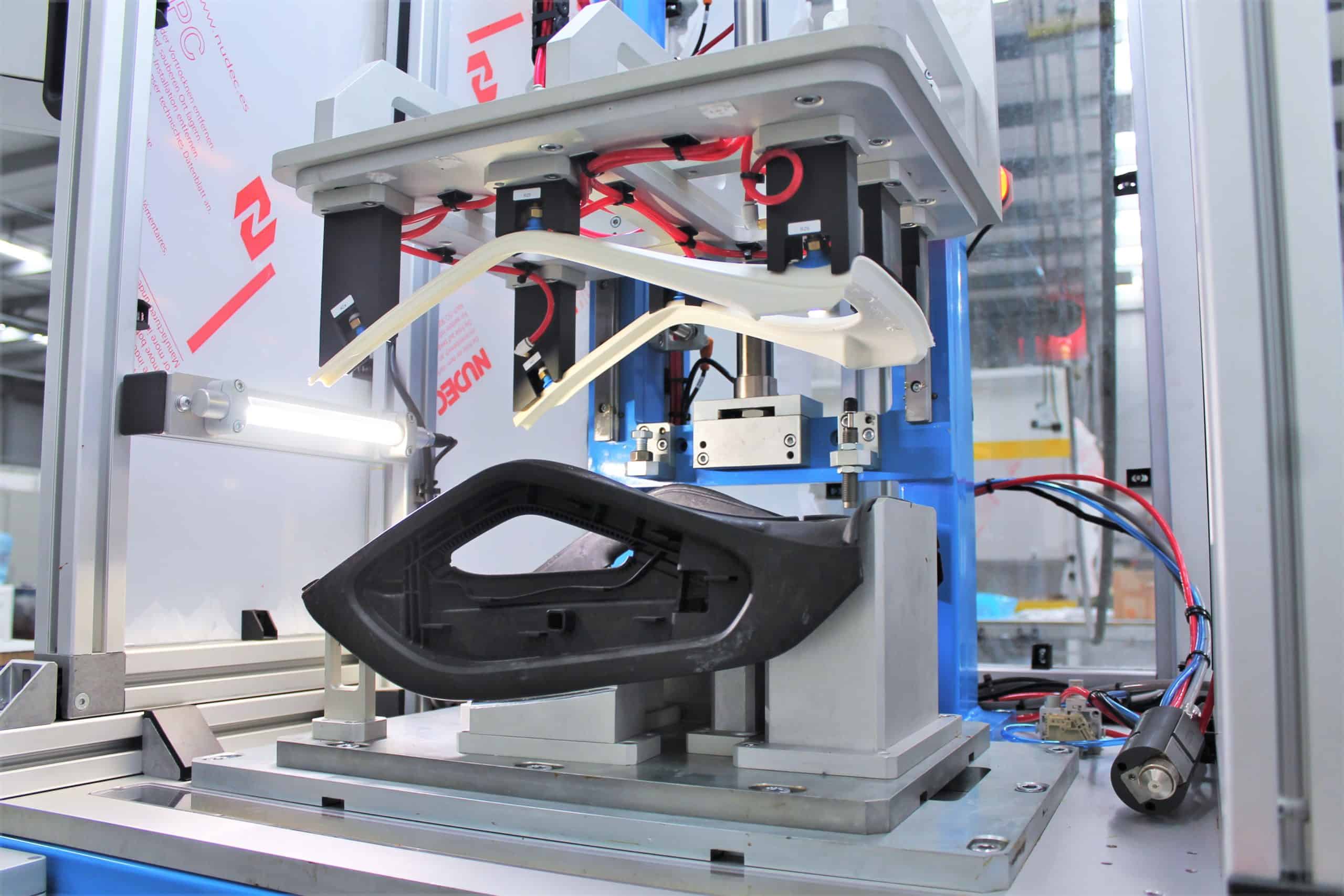

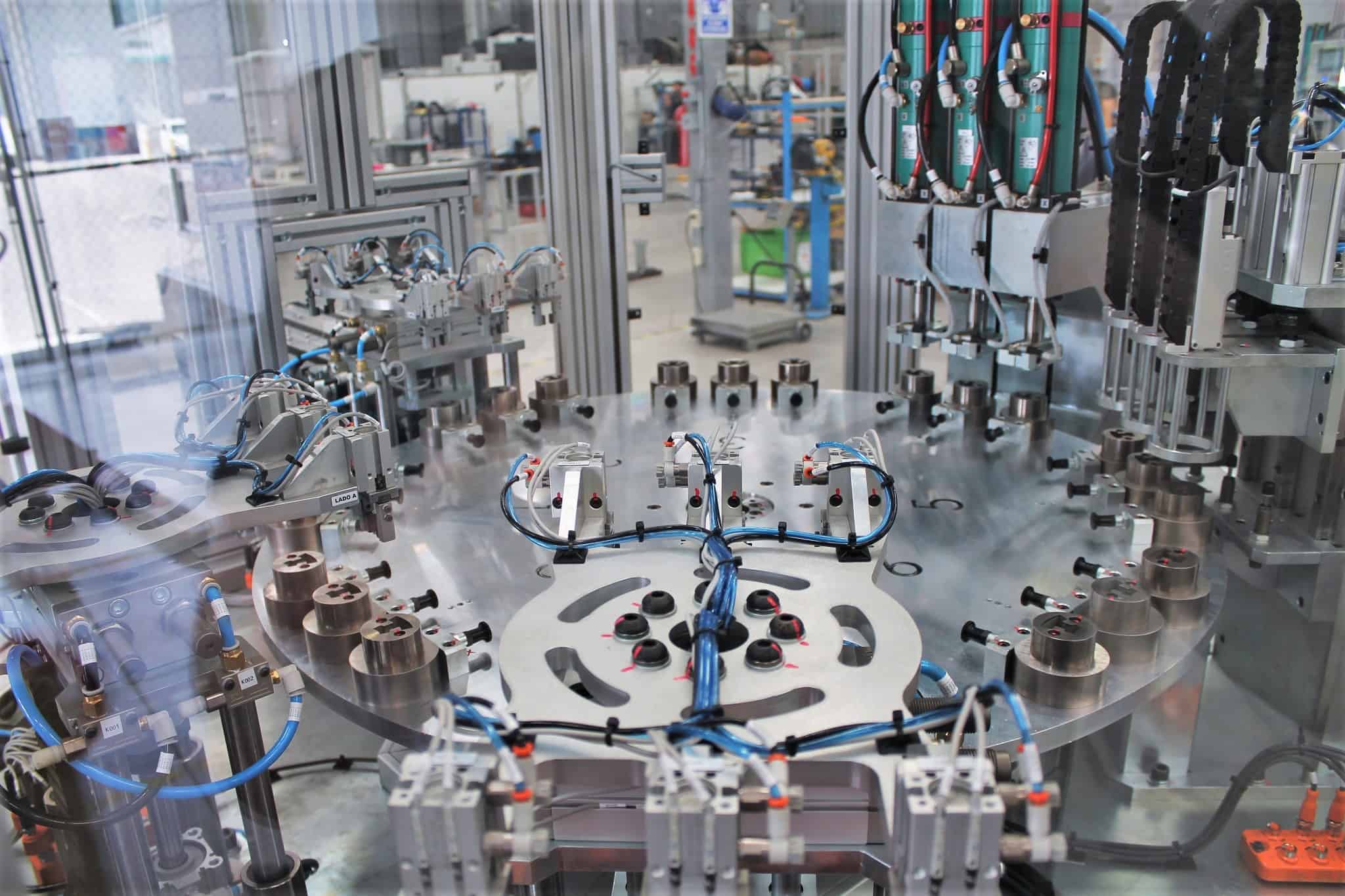

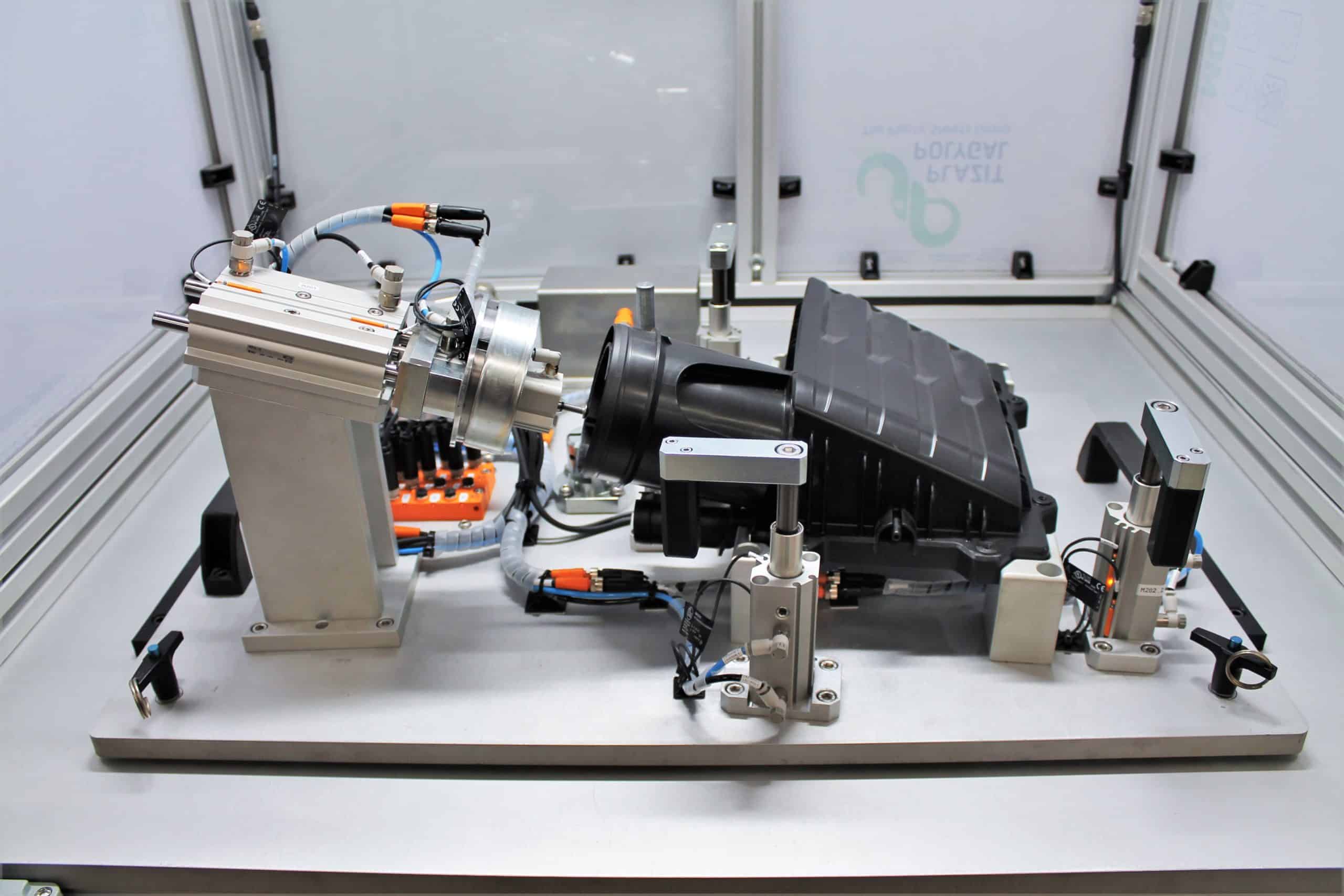

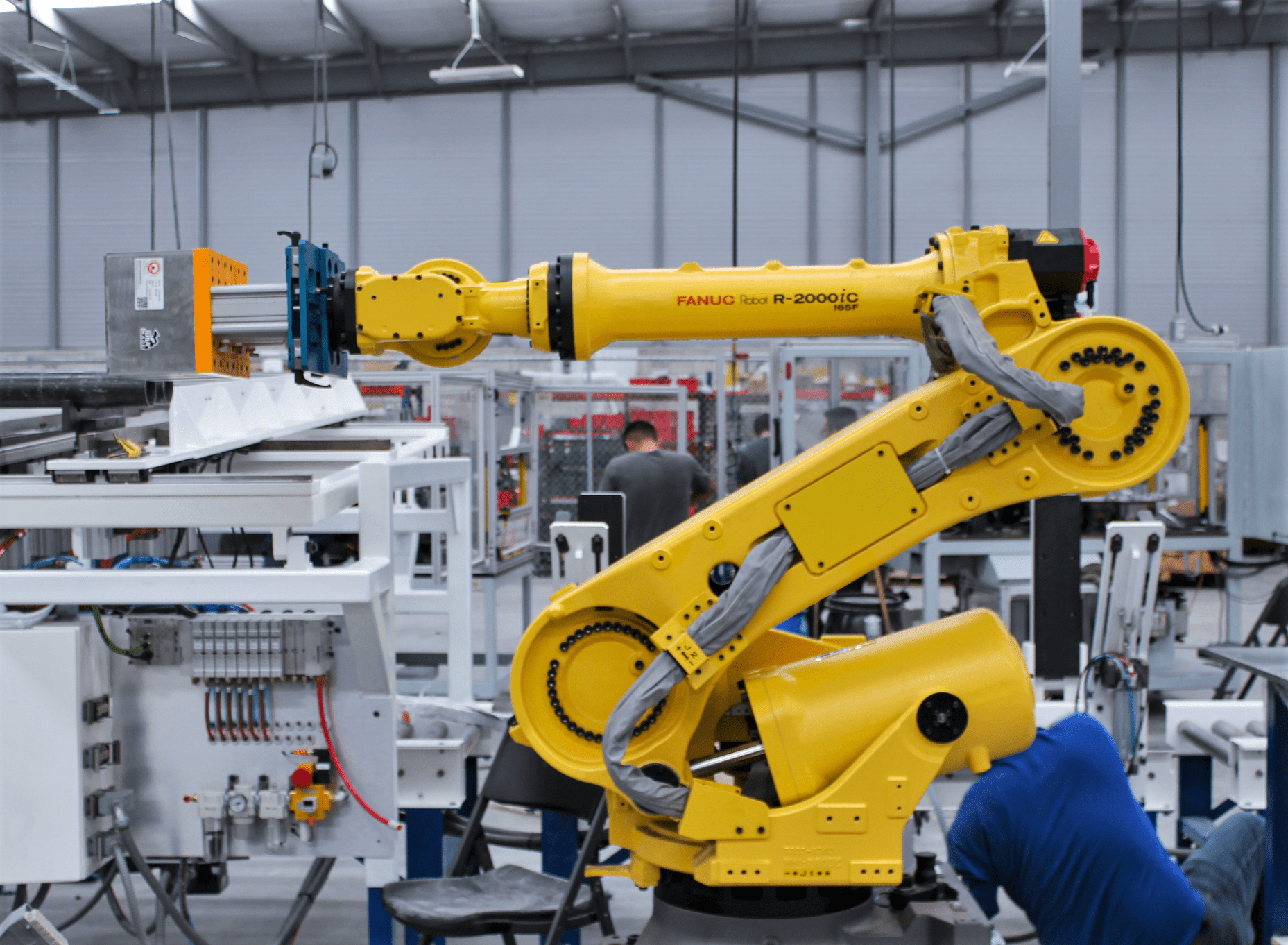

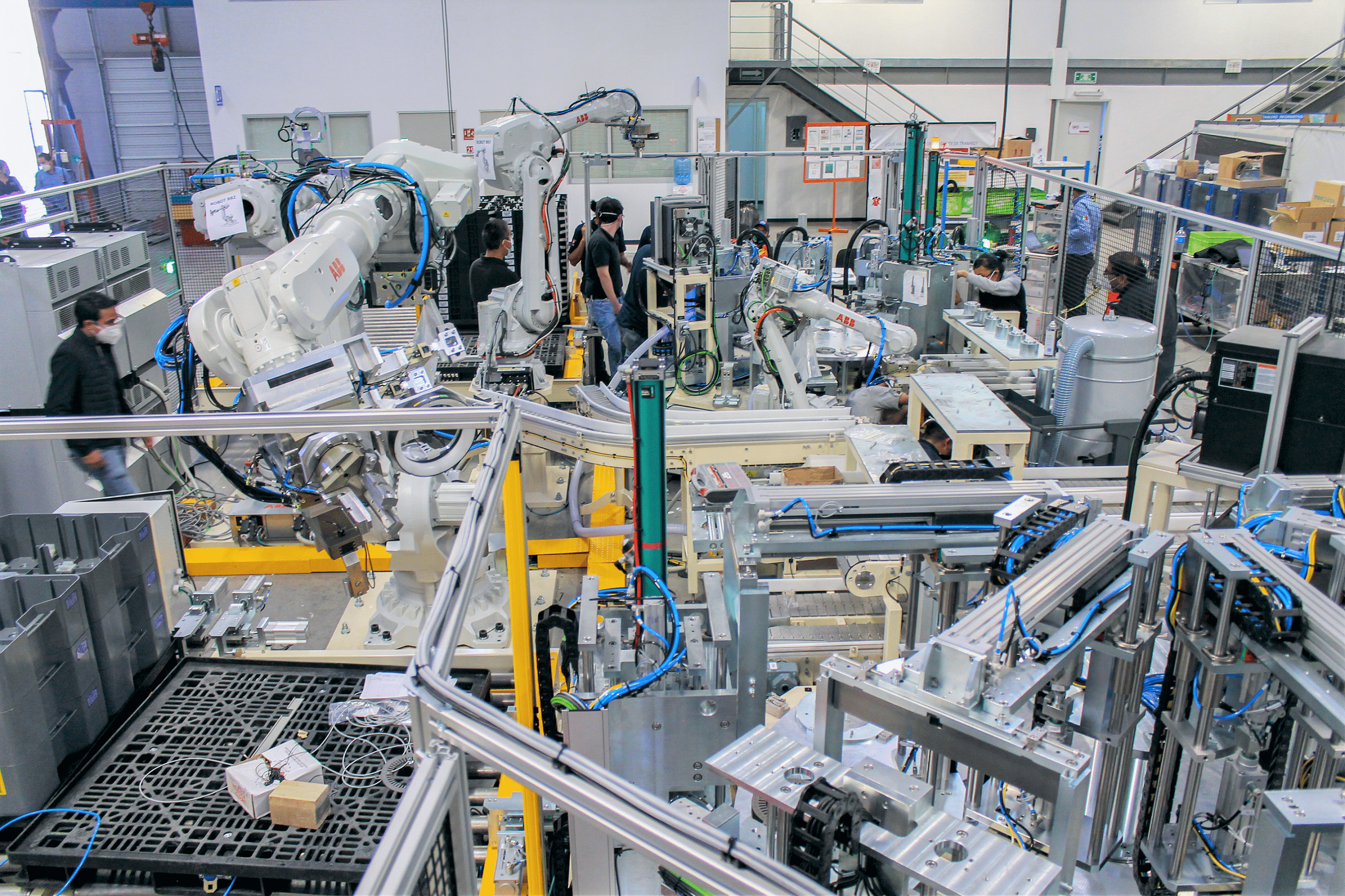

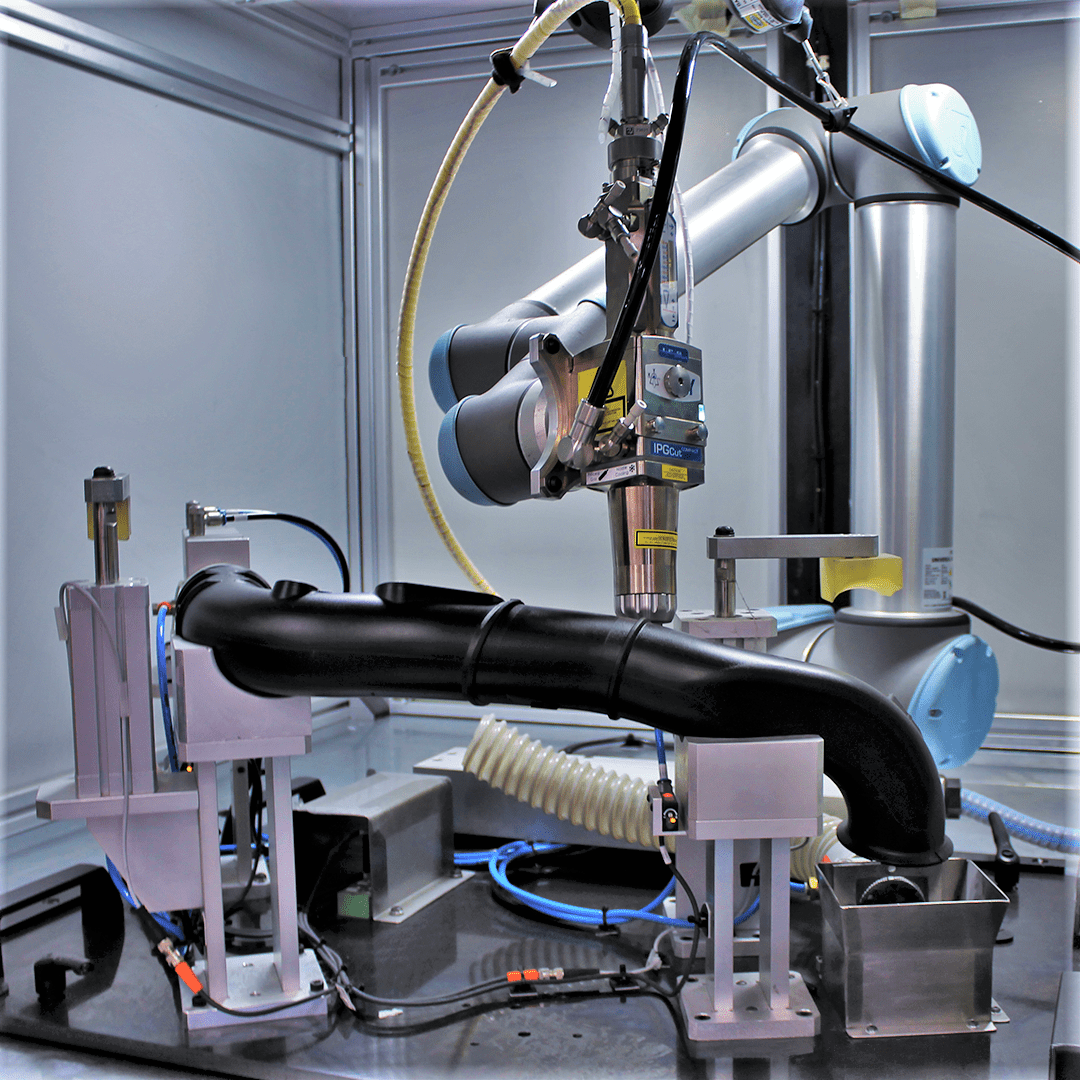

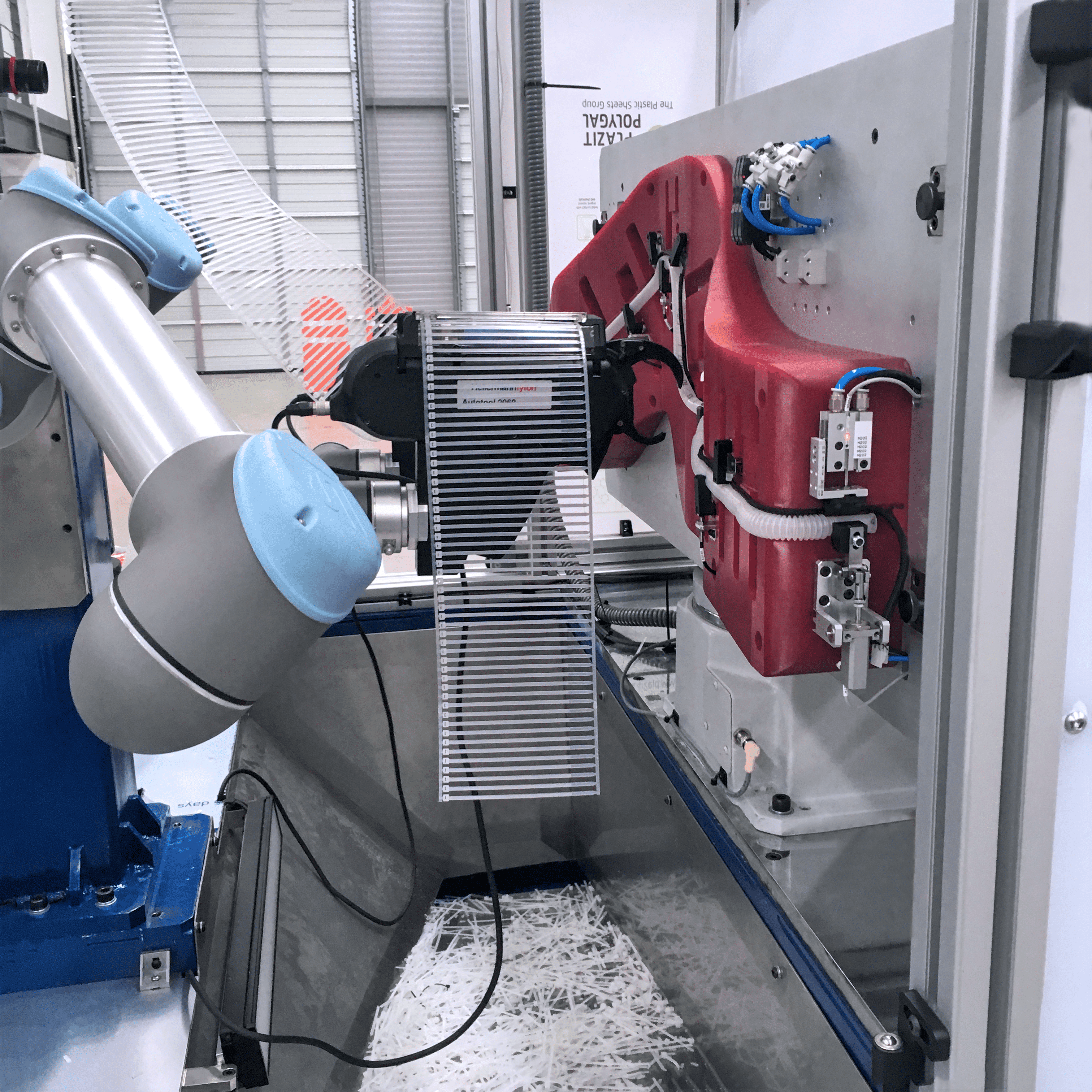

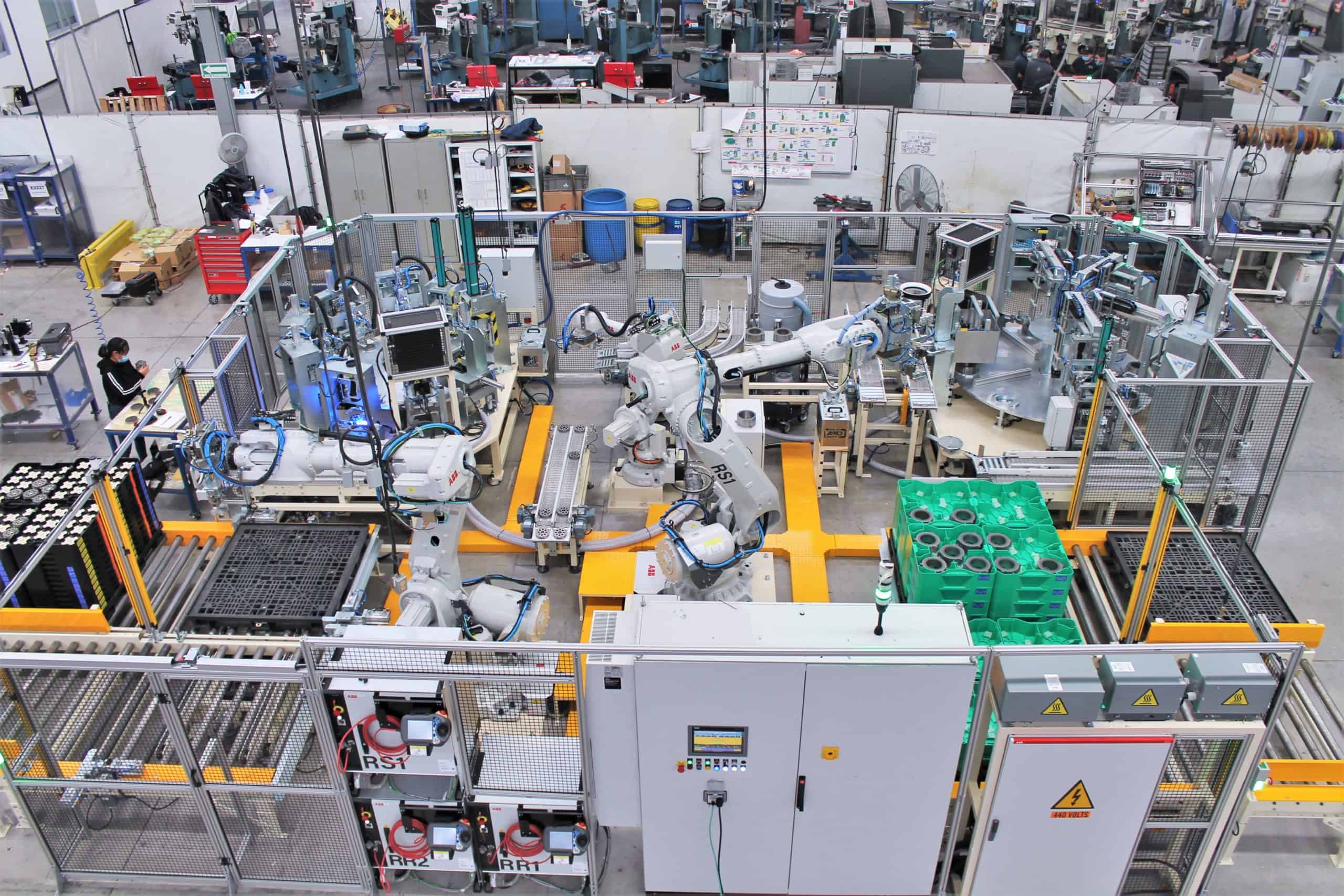

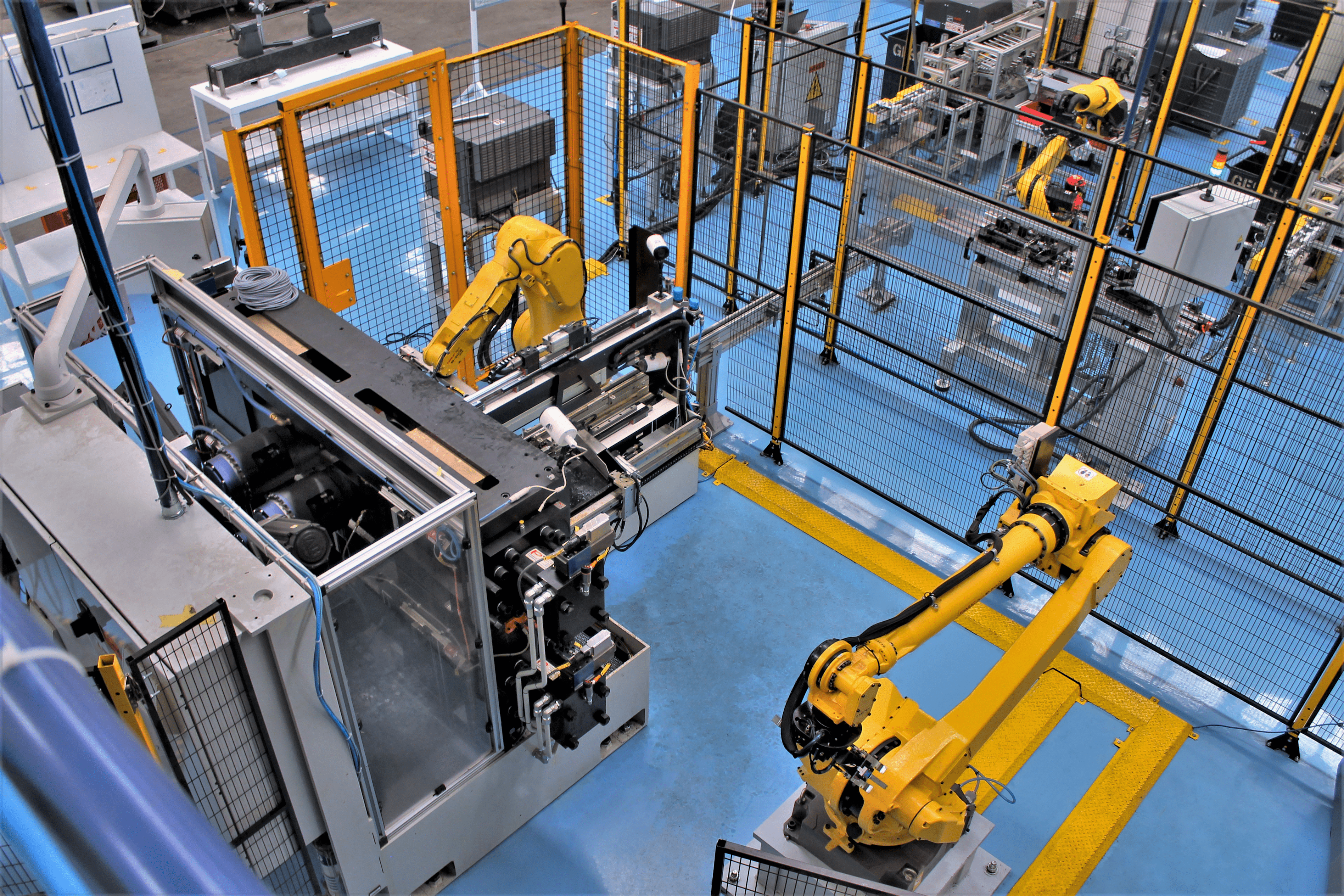

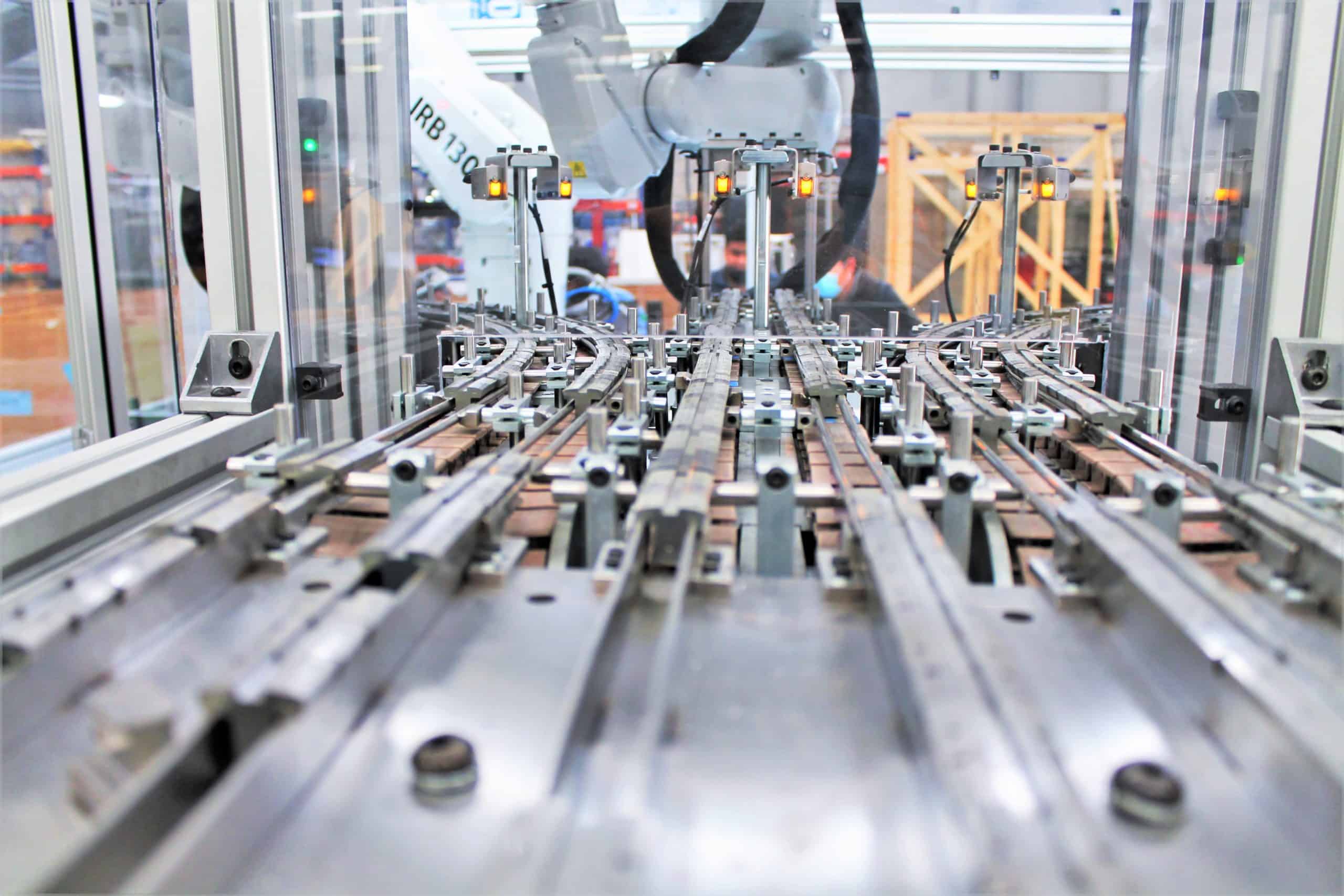

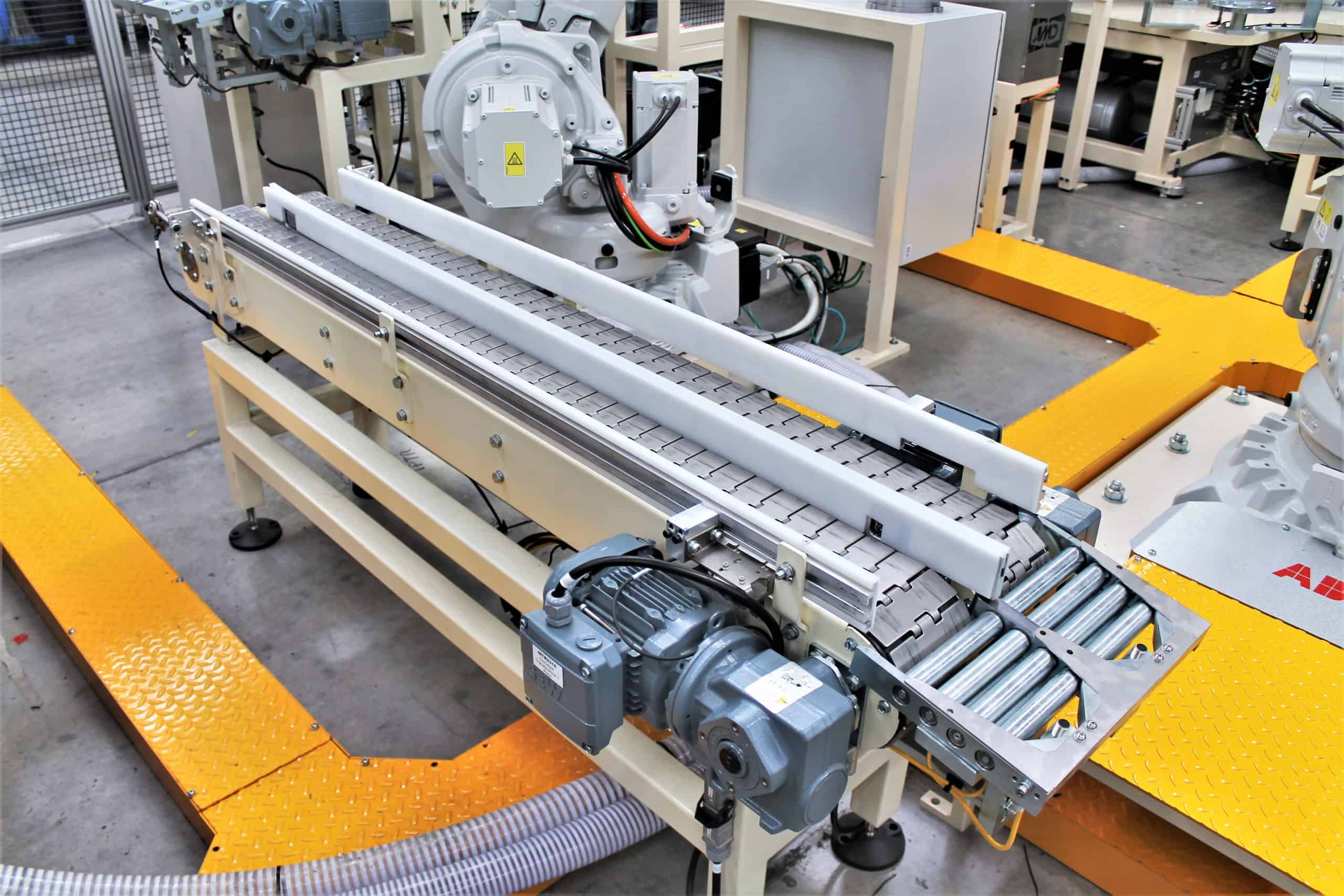

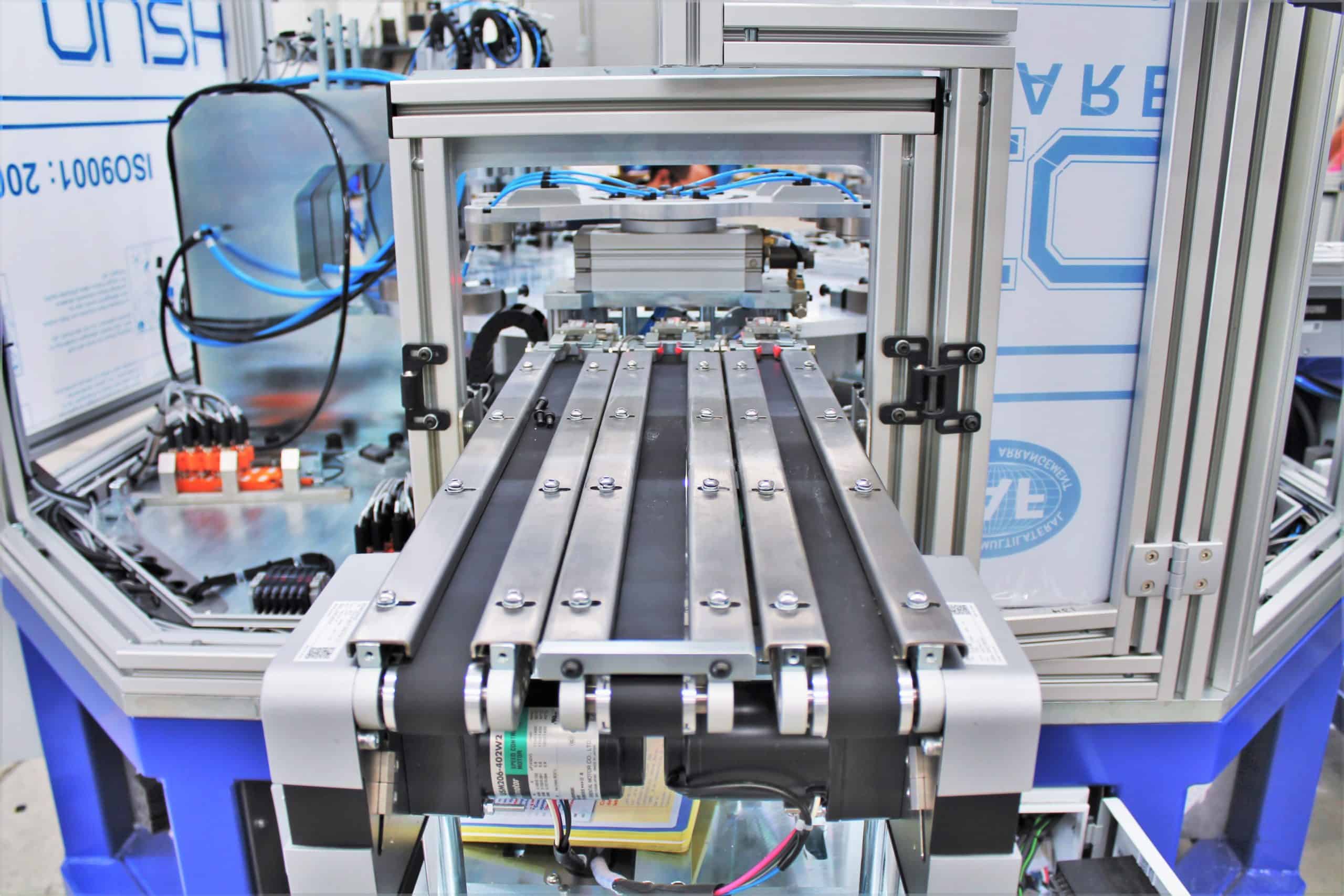

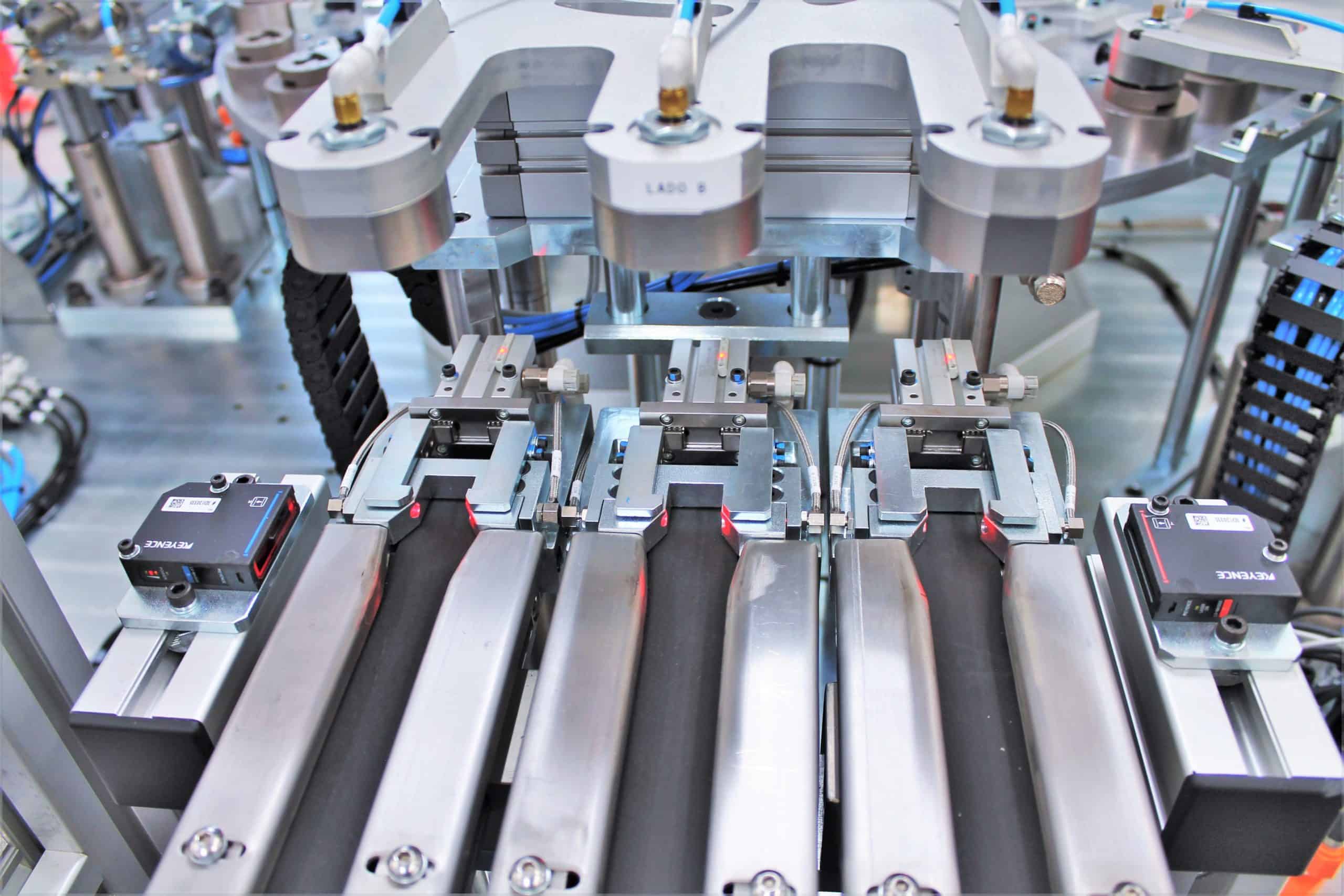

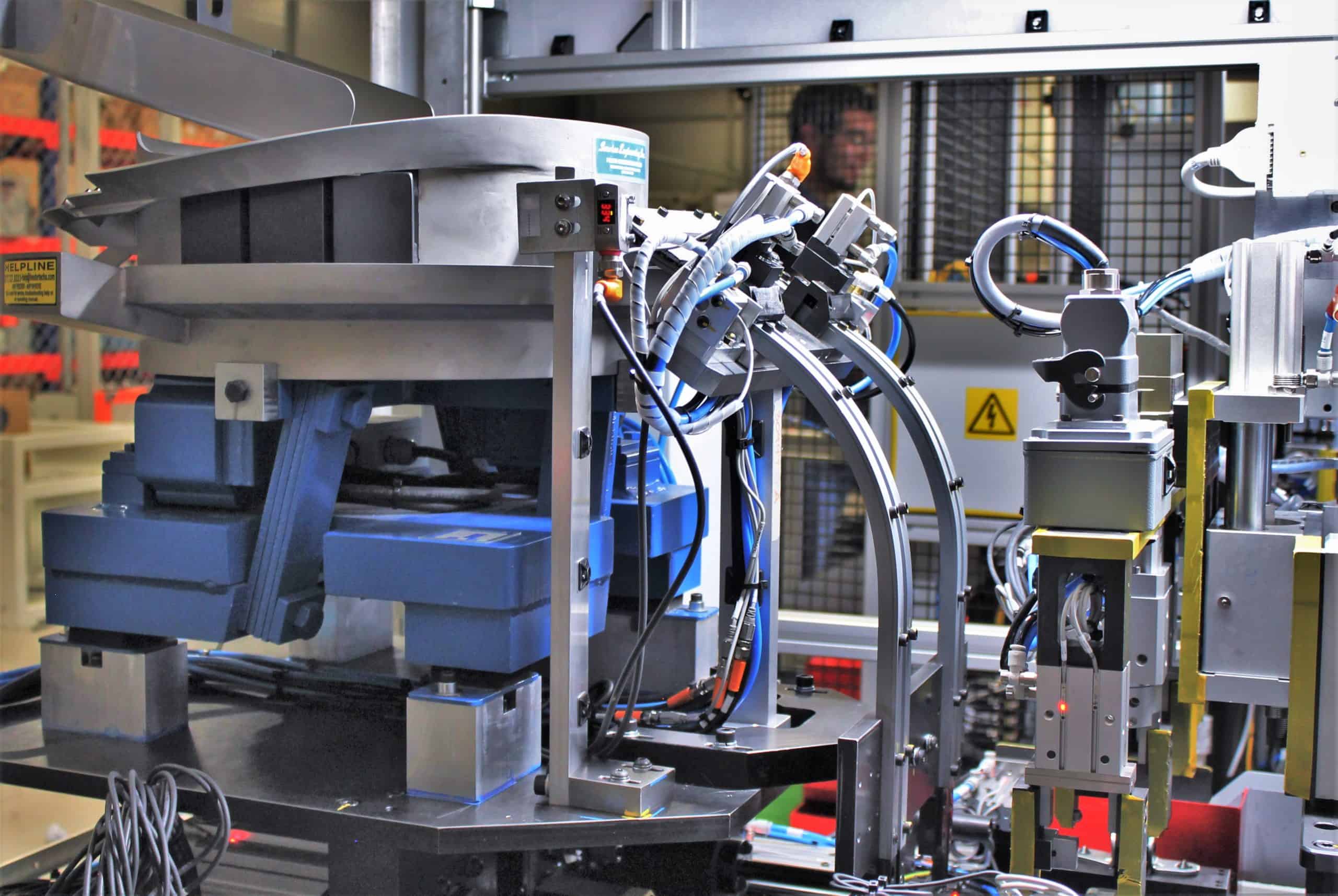

Industrial robotic systems are designed to perform repetitive tasks in a variety of industrial facilities. Industrial robotics can consist of multi-axis robotic arms, automated cells, automated guided vehicles, or conveyance. Today, these systems are highly scalable and flexible to meet the specific needs of various applications. Operators can also easily reprogram these systems in the event of increased demand, product changes, or seasonal changes. This combined accuracy, flexibility, and scalability makes industrial robotics ideal for use in worldwide production lines of low to high volume. AMD creates customized robotic cells involved in processing, including stapling, gluing, packing, assembling, screwing, packaging, marking, printing, quality checks, and much more. At AMD we use standard robots made by other robot manufacturers and integrate them into custom roles. It is important to note that robots are not always the solution, when production is very high and variability is low (only one or two product variations are required) building a dedicated single purpose machine may be a cheaper and more effective option. At AMD we can advise you on the best option.

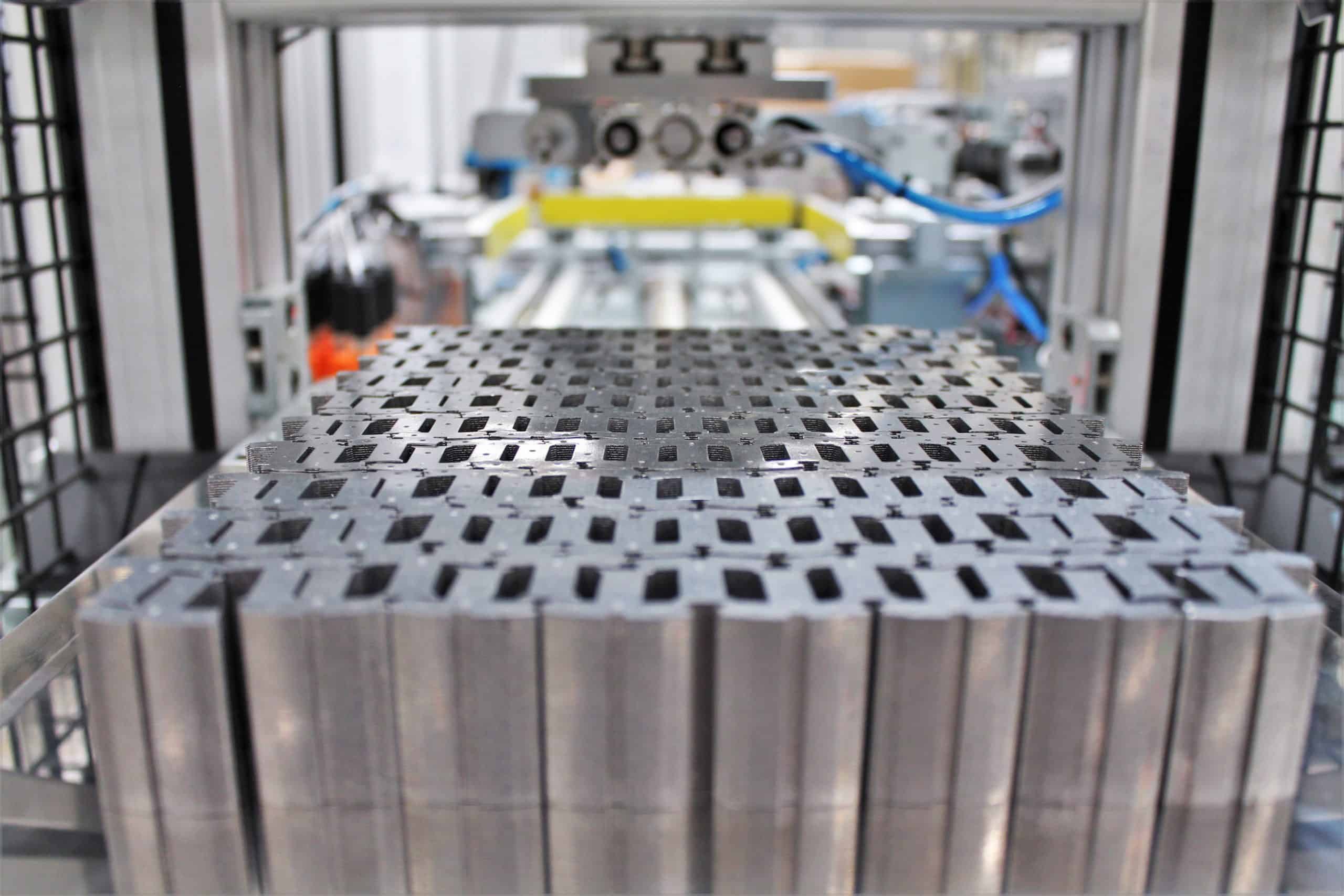

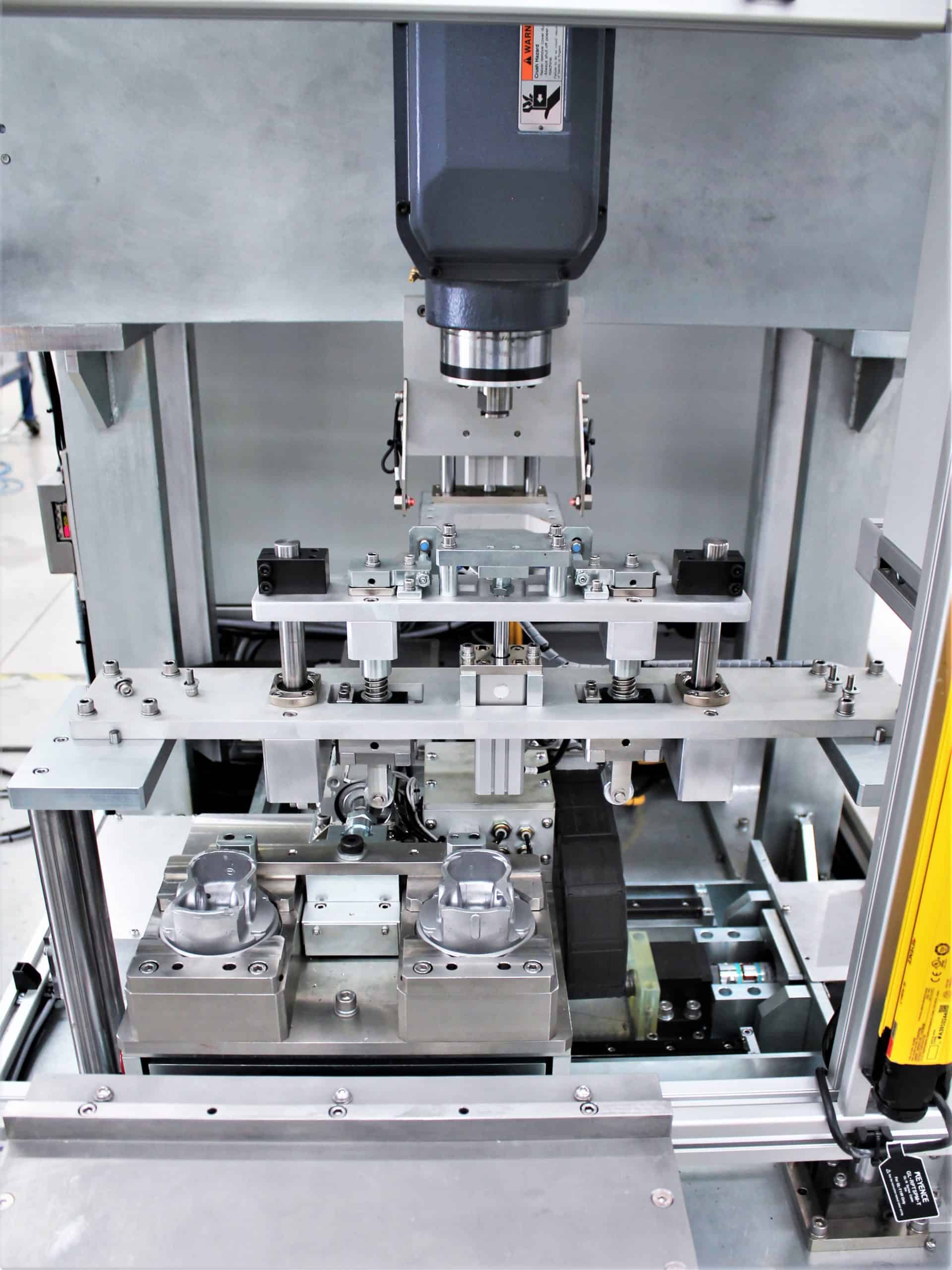

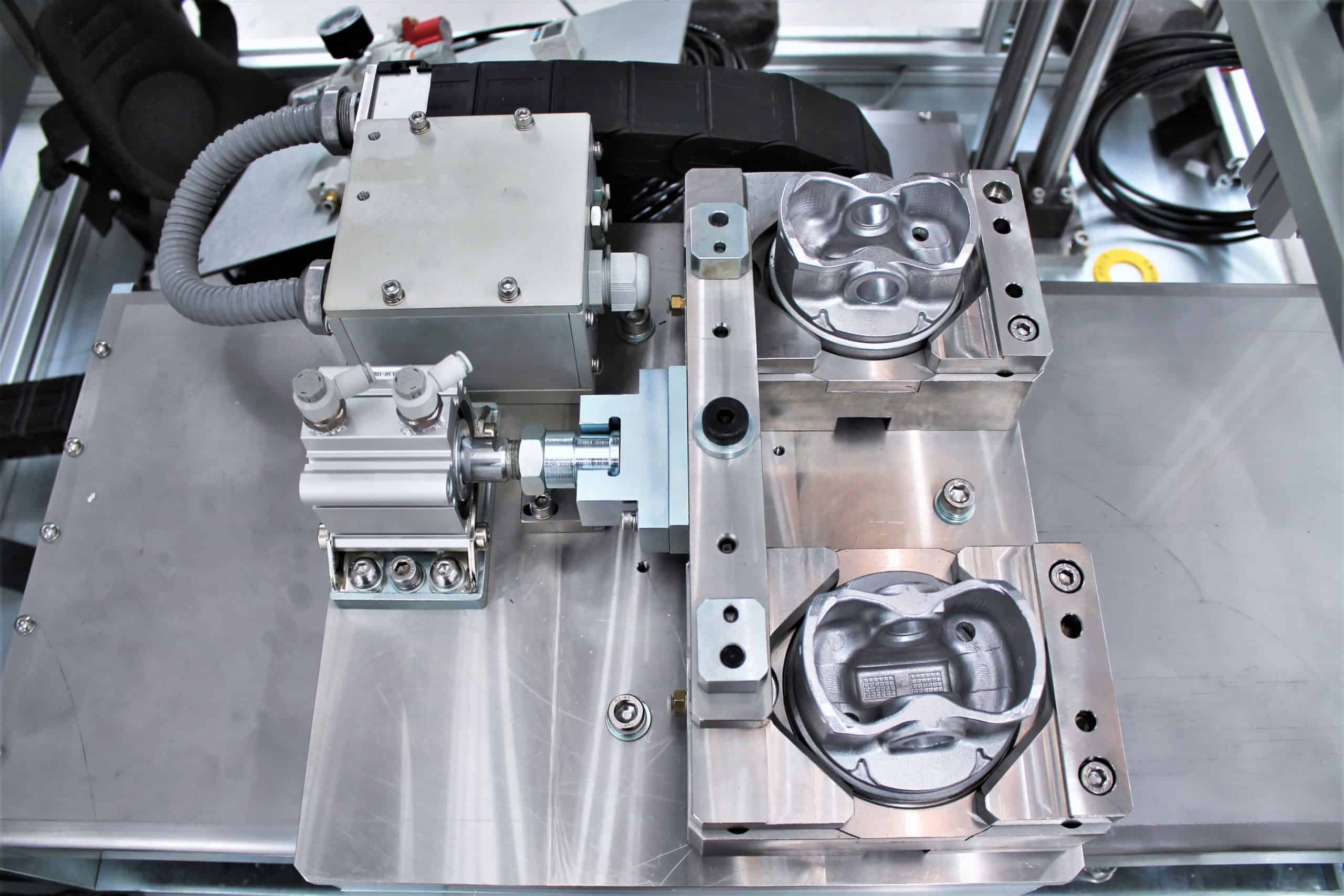

Another issue that you have to take into account when thinking on using Robots is that parts need to be “automation quality”, this means that the quality of the components need to be very stable and uniform. A human operator is able to make small tweaks to correct for part variation when nonconforming parts arrive but a robot is not able to do this. The robot will always repeat the task exactly the same and this requires the parts to assemble exactly in the same movement.