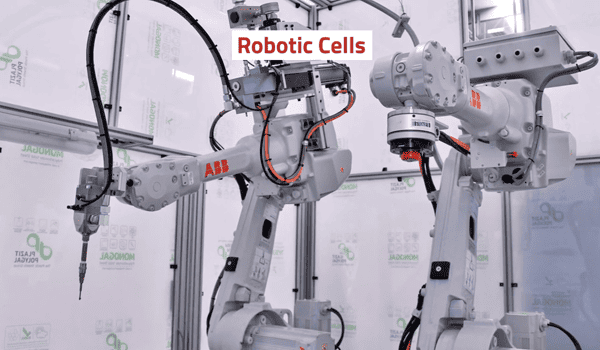

Robotic cells are a hallmark automation solution capable of performing more complex tasks—such as assembly, welding, and inspection—compared to traditional automated machines.

At AMD, we specialize in designing and creating personalized robotic cells for a variety of applications based on our customers’ needs and requirements while optimizing costs and increasing performance.

Components of Robotic Cells

Robotic cells can be made of one or more pieces of existing machinery that perform a certain operation. Facilities can then integrate additional dedicated robots to the machines as needed to optimize production. For example, a lathe or milling machine performing a preset operation may work with other dedicated robots to form a complete robotic cell.

Other robotic cells may begin as existing robots to which new machinery is added to complete the system. In any case, a system integrator is responsible for designing the most effective robotic cell that maximizes safety and makes the most of available space.

Most robotic cells are comprised of the following main components: a robot, auxiliary tools, vision systems, and safety barriers.

Robots

Depending on the space available, the objects to be handled, and the kind of process necessary, the system integrator chooses the robot best suited for its operating environment. Robotic cells could involve several types of robots, including:

- Industrial Robots: Most robotic cells use industrial robots, which are in the shape of human arms with six degrees of freedom. This design offers superior flexibility, heavy-lifting capabilities, and the ability to complete complex operations at varying ranges.

- SCARA Robots: Some operations may use Selective Compliance Assembly Robot Arm (SCARA) robots that can lift lighter objects. These robots don’t offer the same range of motion as industrial robots but are ideal for light-duty applications.

- Delta Robots: Nicknamed the “spider” robot for its shape, the Delta robot handles lightweight objects at high speeds. It is capable of pick-and-place operations at short ranges, similar to the SCARA robot.

- Cobots: Short for “collaborative robots,” cobots tend to work beside human workers and may come with two robotic arms for operation. Unlike other robots, cobots are intended for safe collaboration with human operators, meaning protection barriers aren’t necessary for these systems.

Vision Systems

Another component of some robotic cells are vision systems. Robotic cells may feature 2D or 3D vision that enables the robot’s autonomy through effective guidance. Using vision systems, robots can easily lift and manipulate workpieces from bulk-storage trolleys or trays and place them into machines.

Safety Barriers

The high working speeds and heavy weight of robotic cells and the objects they carry make them potentially unsafe in facilities without the proper precautions. As a result, robots need safety barriers that protect operators during various tasks, including loading and unloading, emergency operations, and maintenance or repairs.

To ensure the safety of workers and the facility, robotic cells can incorporate two main types of safety barriers:

- Physical Barriers: A metal enclosure covers the entire work area of the robotic cell. Operators can access the enclosure via an alarmed door that only authorizes entry when the robot is deactivated.

- Laser Barriers: Laser barriers comprise multiple strategically placed laser sensor devices. Each sensor detects foreign objects or people passing too closely, which triggers the robot—and subsequently the entire cell—to either slow down or cease operations. Once the object is at a safe distance from the sensor and the robot, the robot will reactivate.

Contact AMD for Robotic Cells Today

Robotic cells increase the productivity and safety of facilities that handle assembly operations. At AMD, our experienced team of robotic specialists can design custom robotic cells that handle both standard and unique assembly processes for your business. Contact us today to get started.