The COVID-19 pandemic was an eye-opener for many businesses, revealing their supply chains’ limits and vulnerabilities. Supply chain resilience is the capacity of a supply chain to adapt to unforeseen events. Companies with resilient supply chains not only have the capability to adjust rapidly and continue operations in the face of supply chain challenges, but they are proactive, remaining vigilant and utilizing real-time data to look for potential disruptions or changes to demand and make quick, informed business decisions.

Optimal supply chain resilience means planning ahead and preparing for breaks in the supply chain, enabling organizations to return more quickly to normal production. Read on to learn more about supply chain resilience, how you can strengthen your supply chain for reliable production, and the benefits of working with local partners.

How to Improve Your Supply Chain

Any number of factors can cause your supply chain to break down. In addition to epidemics, some supply chain disruption examples include:

- Extreme weather conditions or geological disasters

- War and incursions

- Cyber attacks

- Labor shortages or disputes

- Transportation or gas shortages

- Component shortages

Given the rise in global sourcing and manufacturing, keep in mind that another country’s circumstances can greatly impact your business in the U.S.

One of the most crucial components of supply chain resilience is contingency planning or preparing to the best of your ability for disruptions. However, merely coming up with a strategy isn’t enough. You must enact your plan and ensure that you review your networks and inventory regularly. This update exercise should entail a business study of your most important suppliers based on SKUs.

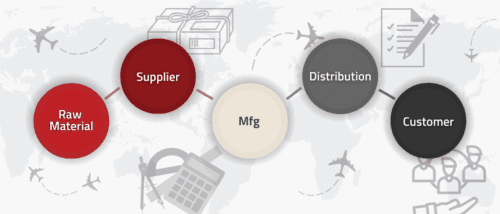

Evaluate your relationships with all of your present suppliers, and then develop a list of viable alternates, giving you an actionable risk management strategy outlining what to do to maintain production if any of those linkages fail. These alternatives may include public and private entities, comparing and diversifying your procurement options to consider domestic, near-shore, and offshore sources. Ultimately, being able to detect and quickly react to supply chain changes requires data-driven, end-to-end supply chain management.

Building a Resilient Supply Chain

While it isn’t possible to account for every situation, supply chain mapping allows you to prepare for the most likely scenarios and determine their potential impacts on your business. It may take a lot of work to break down a distribution network and track key suppliers, but when (not if) there is an interruption, the preparation will save you from downtime and lost revenue.

Creating a supply chain map can be as easy as downloading a free template, or you can utilize computer software programs to examine links in your supply chain. This will require you to not only understand your tier 1 and 2 suppliers and manufacturers, but also to question and research where those businesses source their own products and materials to determine their infrastructure systems.

Mapping is only the first step, however. There are five basic steps to achieving supply chain resilience, and the remaining four are:

- Initial assessment. Once you have completed your research, truly analyze the capacities and capabilities of the businesses in your supply chain through open-source data to pinpoint possible weaknesses.

- Outreach. This stage involves meeting with specific stakeholders and evaluating the results from steps 1 and 2, building cooperative partnerships to improve supply chain resilience and transparency.

- Plan development and implementation. At this stage, you’ll create an actionable plan based on supply chain logistics and other information you’ve gathered and utilize preparedness activities to implement it. Then, in a crisis, you are ready to put your strategy into practice.

- Plan review and revisions. This step is ongoing, requiring you to update and review supply chain data over time, make necessary revisions to the analysis, and keep stakeholders involved for continued supply chain resilience.

AMD: A Reliable Resource in Your Industry Supply Chain

Advanced Manufacturing Development, Inc. focuses on self-sufficiency, stability, and supply chain resilience. Our company experienced vertical growth when we started doing our own CNC machining rather than relying on outside vendors to supply components for our industrial automation solutions. We use our technical expertise to design and create products based on your requirements and industrial standards as the sector continues to experience a need for the rapid manufacture of innovative, complex parts.

Using a local supplier for your machinery and assembly line needs offers you several advantages, such as minimal risk for supply chain interruptions, increased service options, a more extensive inventory, and economical pricing while maintaining a high degree of quality. AMD offers products and services like robotic cells, assembly line and custom automation equipment, test systems, welding, leak detection, branding, and traceability to support local businesses and improve operations.

If your existing supplier cannot meet your demand or quality criteria for services or machinery, let AMD customize a manufacturing solution for your business. Contact us for more information or request a quote today.

1 Comment

Zoey

Excellent post, very informative.