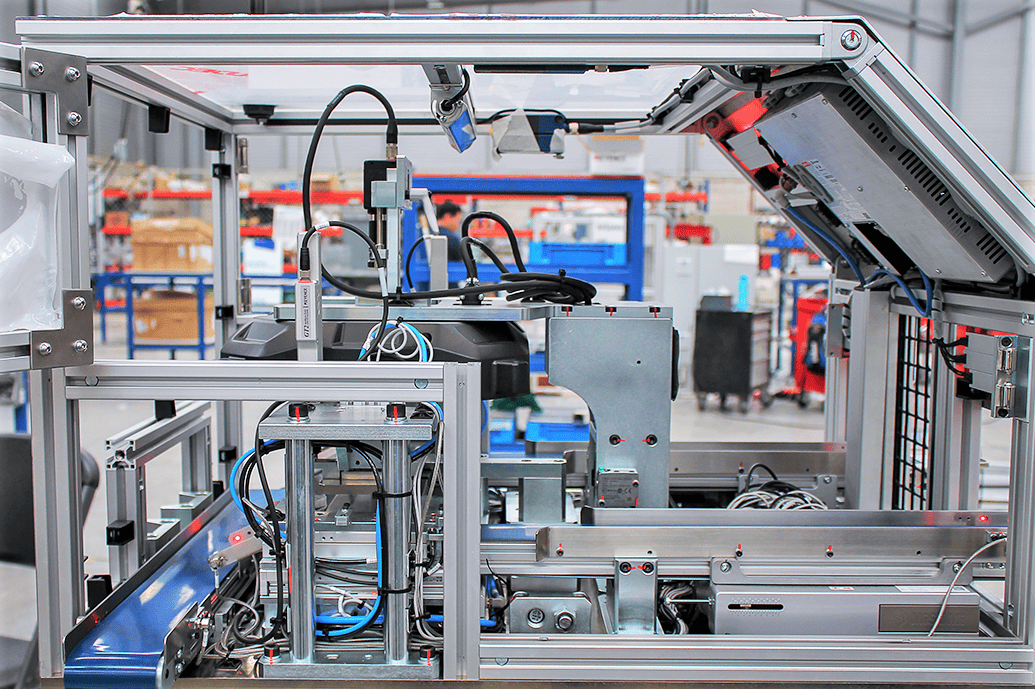

Automated assembly lines have revolutionized manufacturing processes across various industries, offering increased efficiency, precision, and productivity. To create a highly customized and efficient automated assembly line, you need to carefully select the equipment that suits your specific requirements.

In this blog, we will explore the key components of an automated assembly line and discuss different brand alternatives for each section. These components include Programmable Logic Controllers (PLCs), sensors, vision systems, pneumatic and hydraulic systems, robots, feeding systems, and servo presses.

Programmable Logic Controllers (PLCs)

PLCs are the brains behind an automated assembly line, responsible for coordinating all the operations. They control the machines, conveyors, and other equipment to ensure seamless production. When choosing a PLC, you have several reputable options, including:

- Siemens: Known for their reliability and advanced features, Siemens PLCs are widely used in industrial automation. This is a great alternative that offers great service across the U.S. and Mexico, with competitive pricing and better lead times.

- Allen-Bradley (AB): Another industry giant, Allen-Bradley offers a range of PLCs suitable for various applications. During the pandemic, they were heavily impacted by supply chain issues, and getting hold of some of their equipment could mean waiting close to one year. They have fixed some of their issues and lead times are much better now. If you are planning on using them, be aware of their lead times.

- Omron: Omron PLCs are favored for their user-friendly programming and robust performance. They are increasingly becoming a second choice when AB or Siemens is not available. They are a relatively newer brand and will take some years to become as popular as other established players.

There are many PLC brands, and they all can deliver great functionality. The key is to choose a brand that offers great support in your location and matches your internal capabilities.

Sensors

Sensors play a crucial role in detecting and monitoring various aspects of the assembly process. Depending on your requirements, you can choose from brands such as:

- Keyence: Keyence offers a comprehensive range of sensors, including photoelectric, proximity, and vision sensors, all known for their accuracy. We personally love working with Keyence. They offer great customer service and are our first choice when it comes to developing a new application. Their cameras are great, too.

- Sick: Sick sensors are recognized for their durability and reliability in harsh industrial environments.

- Banner Engineering: Banner Engineering provides a variety of sensors, including ultrasonic and laser sensors, designed for precise measurements.

When it comes to choosing the right brand, it’s key to look for the brand with the best engineers who will offer support when developing an application or trying to fix your current system.

Vision Systems

Vision systems are essential for quality control and inspection tasks on the assembly line. There are several brands that offer vision systems. But when it comes to the best performance and service, only two come to mind:

- Cognex: Cognex is a leader in machine vision systems, offering high-resolution cameras and software for defect detection and identification.

- Keyence: Keyence also provides advanced vision systems that integrate seamlessly with their sensors and automation equipment.

These systems offer very robust applications, and each has its own advantages and disadvantages. We recommend you reach out to both companies and compare their proposals. In the end, it comes down to the engineers that will support your location.

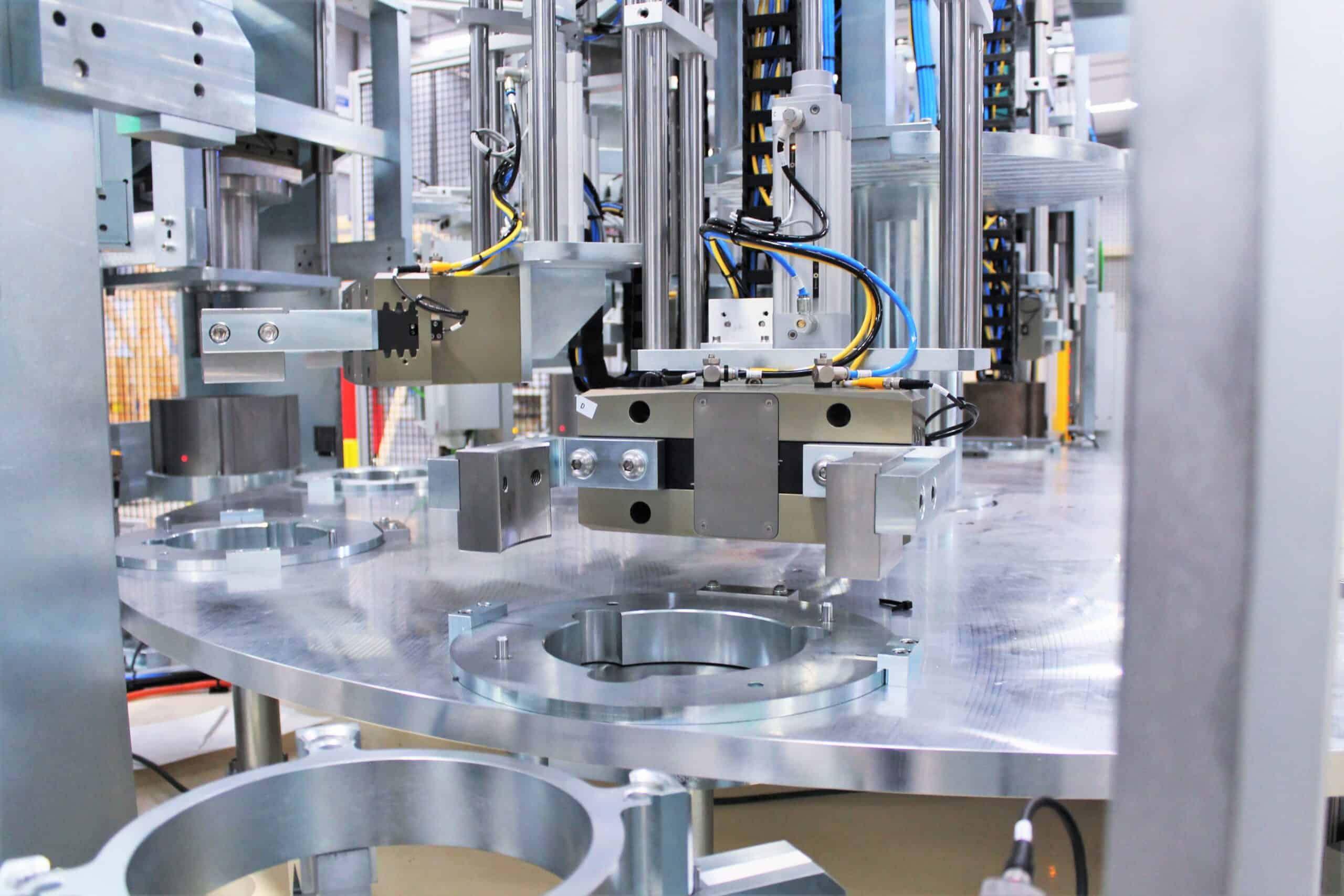

Pneumatic and Hydraulic Systems

Pneumatic and hydraulic systems are critical for controlling the movement of components and tools. Brands to consider for these systems include:

- Festo: Festo is a leading manufacturer of pneumatic and hydraulic components, known for innovation and efficiency. They are a great choice when it comes to standard applications. There are some brands that offer incredible solutions that can cost 10x more. You can think of Fest as the no-frills, reliable solution.

- Parker Hannifin: Parker Hannifin offers a wide range of pneumatic and hydraulic solutions suitable for industrial automation. They are incredibly popular and have been doing pneumatic and hydraulic systems for years. You can’t go wrong with them. We would recommend you reach out to your local rep and have them take a look at your application.

- SMC Corporation: SMC is known for its high-quality pneumatic products and comprehensive automation solutions. Similarly to Fest, you can think of SMC as the no-frills and reliable solution. We love working with them as they offer great learning opportunities for our engineers. Every few weeks they come to our facility, showcase their products and any new developments, talk to our engineers regarding current projects, and recommend products.

Robots

Industrial robots are increasingly integrated into automated assembly lines. Some top robot manufacturers include:

- Fanuc: Fanuc is a global leader in industrial robots, providing a wide range of robotic solutions for manufacturing. They are very popular in the U.S. due to their service and incredible capabilities. Choosing a robot brand has more to do with the brand representatives who are close to you and the financial conditions that they offer.

- ABB Robotics: ABB Robotics offers flexible and efficient robotic systems suitable for various applications. They are our favorite brand to work with and we have developed a very close relationship with them throughout the years. We have experience working with several robot brands, and we consistently choose ABB robots when we need to move heavy items fast!

- Universal Robots: Universal Robots specializes in collaborative robots (cobots) designed to work alongside humans safely. They have become a household name and are an increasingly popular choice for new applications. Our only concern with them is that engineers tend to overuse them. They are reliable but can run into limitations when the application requires the robot to perform complex tasks like moving a large amount of weight very fast and with great precision. If your application is simple, they are a great choice!

Keep in mind that we left out many robots that are used across the industry. Other great brands are IAI, Epson (both IAI and Epson are our top choices when it comes to very fast robots), Yaskawa, and many others. We have worked with pretty much all of them, and they all offer great, reliable products.

Feeding Systems

We rely exclusively on third parties to provide our feeding systems. These companies ensure a reliable supply of components to the assembly line. Feeding systems are a component that is traditionally overlooked by many novice engineers, but you can’t imagine the problems that can come when you have problems with the feeding system. We recommend reaching out to a U.S.-based manufacturer of feeding systems and having a detailed understanding of their capabilities and limitations before purchasing a piece of equipment. There are many cheap solutions available, but please don’t let money be the driving factor for your destination—it could bring you problems down the road.

We have been working with the same company for more than 20 years, and they are great! We won’t disclose their name as we consider them a trade secret (but if you really want their name, just send us an email and we would be more than happy to introduce you).

Servo Presses

Servo presses are used for precise and controlled assembly and fastening processes. Some notable servo press manufacturers are:

- Promess: Promess specializes in electro-mechanical servo presses designed for force and position control. Insider tip—the company is divided into two separate entities, so there are two independent sites you can visit: the German site and the American site. Make sure you are always contacting the German team, as they have pretty much the same equipment but at a substantial discount.

- Pressotechnik: Pressotechnik provides advanced servo presses for various assembly and joining applications.

Contact AMD for More on Choosing the Right Equipment

Creating a customized automated assembly line requires careful consideration of the equipment and components you select. Each brand mentioned in this blog has its strengths and may be better suited to specific applications or industries. It’s essential to evaluate your production needs, budget, and long-term goals to make informed decisions when choosing equipment for your automated assembly line. By selecting the right equipment and brands, you can maximize efficiency and productivity while ensuring the highest quality of your manufactured products.

At AMD, we have developed custom-built automation solutions with pretty much every brand available. Let us know if you have any questions, or request a quote to speak with a team member about the automation solution for your application.