ROIC Considerations of Industrial Automation Equipment for Manufacturing

Leave a CommentAutomation equipment can deliver significant value to manufacturing companies if done right. Automation projects should always be justified from a financial standpoint, so it’s important to select a solution that fulfills production needs while being able to minimize costs over the long term.

At Advanced Manufacturing Development (AMD), our team has more than 25 years of industry experience creating automation solutions that fit our clients’ budgets and business strategies. We have over 100 engineers and technicians that can incorporate cutting-edge automation technology into individual assembly stations, high-speed stations capable of managing 100 ppm, and fully automated manufacturing lines. Since we first opened our doors in 1996, we’ve completed more than 1,500 industrial automation projects.

Start your project by considering the different degrees of industrial automation—and the potential financial costs and benefits of each system—to zero in on the right fit.

Degrees of Automation

There are four degrees of automation used in manufacturing facilities:

Manual Operation

This is the lowest level of automation where all tasks are performed manually by human operators. There is no involvement of automated systems or machinery.

Partial Automation

At this level, some tasks or processes are automated while others still require manual intervention. Certain repetitive or time-consuming tasks may be automated to improve efficiency and reduce human error.

Process Control Automation

At this level, the focus is on automating control systems for monitoring and regulating specific processes. Automated control systems, such as programmable logic controllers (PLCs) or distributed control systems (DCS), are employed to manage and optimize process variables.

Full Automation

Full automation refers to a system or process where all tasks and operations are completely automated, and human intervention is minimal or non-existent. The system can perform complex functions independently without the need for constant human monitoring. Full automation does require having an experienced technician that can address any issues the machine might encounter over its lifetime.

Breaking Down the Benefits of Manufacturing Automation

Automation brings numerous unique benefits, and it is one of the most important long-term investments manufacturers make in their facilities. A successful automation solution will provide benefits in one or more of the following areas:

- Production Volume: An automated line could increase production volume under a set level of constraints. We usually see this when our customers are having trouble meeting demand for their products, or are constrained by a low supply of labor, space, or time.

- Cost Decrease: Automation systems are highly relevant for customers that are having trouble sourcing the right talent for their manufacturing operations. A single automated system can help your existing workforce be more efficient and decrease the need to hire and retain additional headcount. This is particularly relevant in a tight job market.

- Quality Improvement: Automated systems will deliver great repeatability across a wide range of complex manufacturing operations such as welding, assembly, machining, and more.

Breaking Down the Costs of Manufacturing Automation

Automated solutions require a significant capital investment and some ongoing costs associated with the new equipment, such as:

- Experienced Workforce: For most automation systems, your organization will need to retrain or hire and train employees that can service and operate your chosen solution.

- CAPEX: This includes the automation system itself and ancillary hardware and tools. Setting up the equipment will also represent other discrete and continuous expenses such as rent for the space, shipping costs, etc.

- Maintenance: This includes all expenses associated with the maintenance of the equipment. This can include changing equipment once its useful life is over, replacing parts that are under stress, and preventive maintenance of equipment systems such as hydraulics, pneumatics, electrical, etc.

By categorizing these benefits and costs, your organization can understand the automated solution’s ROIC, where those costs fit into your budget, and determine what level of automation is best for you.

Other Cost Considerations for Manufacturing Automation

Total cost considerations can be complex to estimate. Consider these costs that are usually overlooked as you finalize your estimates:

- Comprehensive purchase price, which may include:

- Getting a higher-quality automation system that meets regulatory standards in your industry

- Safety requirements

- Switching platforms

- Costs incurred throughout the system’s usable lifespan:

- Cost of variable life cycles

- Potential downtime during repairs, maintenance, and modifications

- Inefficiencies after adoption

- Cost of training

- Scalability needs

Your new automation systems won’t immediately be optimized for your production. New automation systems need time to reach their full potential and become a seamless part of your processes.

Request a Quote for a Precise Cost-Benefit Breakdown for Your Next Project With AMD

At Advanced Manufacturing Development (AMD), we partner with each client to help develop a cost-effective plan for automation. Learn more about the costs and considerations of implementing automation by calling our team . You can also request a quote by contacting our team online.

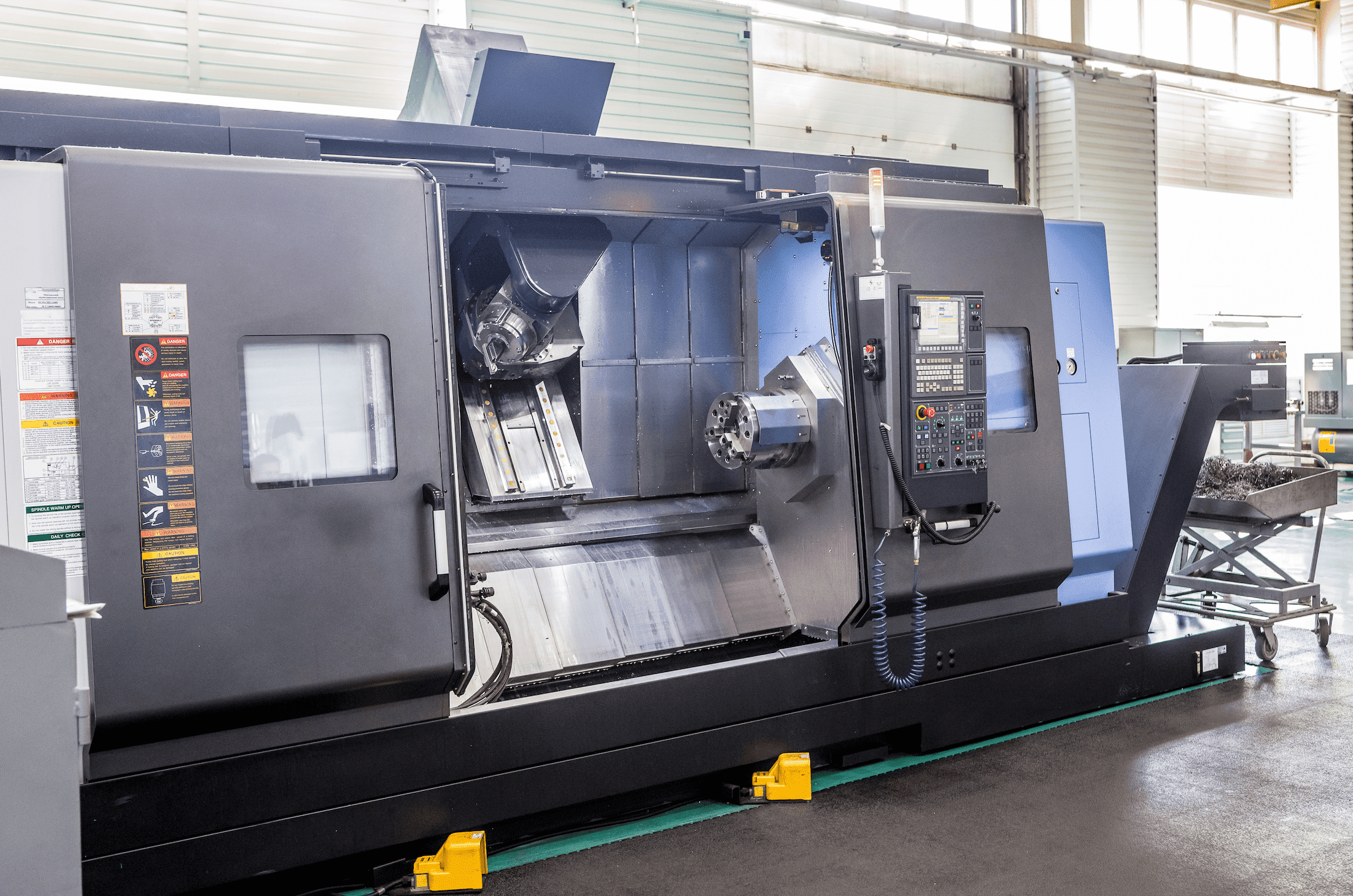

A CNC machine allows operators to create components that would be very difficult or impossible to produce manually. Every machine is made of three basic parts: a command center, a drive system, and a feedback system. CNC technology can use a set of computer prompts to create complex 3D shapes out of metal, plastics, or wood.

A CNC machine allows operators to create components that would be very difficult or impossible to produce manually. Every machine is made of three basic parts: a command center, a drive system, and a feedback system. CNC technology can use a set of computer prompts to create complex 3D shapes out of metal, plastics, or wood.