As automation technology continues to advance, every industry is feeling the pressure to shift from traditional manufacturing and processing methods. The food and beverage industry is no exception. Companies that handle food and beverage processing, manufacturing, and packaging are incorporating automation to enhance their supply chain visibility, improve worker safety, and reduce overhead costs.

The benefits of automating food production are myriad. Automation reduces the amount of labor needed for dangerous or repetitive tasks, freeing up your workers to tackle more complex and fulfilling work. Your workers will be safer, and with fewer hands in the manufacturing process, you will also reduce the potential for human error. Automated food and beverage processing is faster than traditional methods, so you benefit from a quicker, more efficient production of higher quality products. Finally, automation allows you to clear, clean, and repurpose production areas quickly, making it easier to diversify your production capabilities and expand your product offerings.

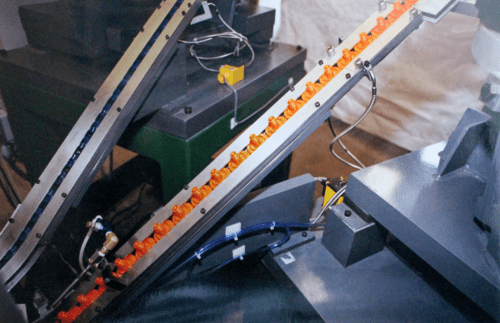

As more and more companies recognize its advantages, automation is becoming increasingly ubiquitous in the food and beverage industry. In fact, many companies are incorporating automation equipment into their operations in order to remain competitive. Some industry applications that benefit from automation include food sorting, beverage mixing, primary and secondary packaging, cleaning and sanitizing operations, bottle filling, tray-loading, product sorting, and more.

Automated Solutions for the Food & Beverage Industry

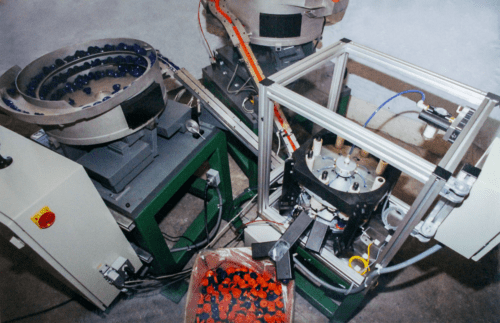

Automation is truly the wave of the future for the food and beverage industry. Already, many aspects of food and beverage processing, from raw materials through packaging and distribution, are handled with robotic and automated equipment. Some of the most common automated equipment solutions used in the food and beverage industry are included below.

Marking & Tracing

Food and beverage packaging is marked with barcodes, serial numbers, expiration dates, and more. Barcodes can be coded to contain a wealth of information, from ingredients to manufacturing dates, times, and locations. Manual or automated scanners can be used to read these codes and trace products from their point of origin through distribution. Using this information, manufacturers and distributors can easily identify, locate, and recall bad or defective products, and then trace the problem in order to eliminate it at the source.

Robotic Vision Systems

Robotic cells with state-of-the-art vision systems are used to facilitate consistent quality throughout the manufacturing process. They help to ensure correct product positioning, add ingredients, and assemble products. They are also critical for a variety of packaging operations, where they fill packages with food products, add full containers to boxes for shipping, and place boxes on pallets.

Automated Welding Systems

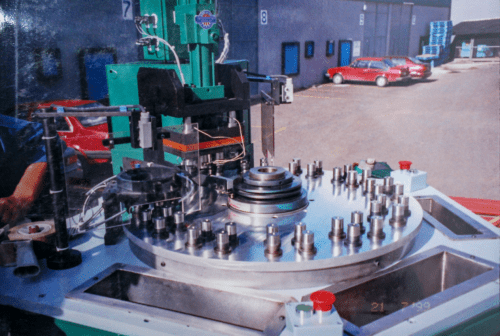

Automated welding systems are used to quickly create and apply bottle caps and seal containers for food and beverage products. These systems are also used for manufacturing a variety of food and beverage processing and dispensing equipment.

Product Quality Testing

Automated quality testing allows you to ensure that your product is well-packaged and consistent with industry standards and regulations before it leaves the facility. Quality testing includes testing food and beverage processing equipment and components, testing dispensing equipment for functionality, and testing product packaging for sealing integrity.

At Advanced Manufacturing Development (AMD), we specialize in the design and fabrication of automated systems that are specifically engineered to meet the particular needs of your application. With increasing demand for quicker, smarter, and more complex automation solutions, our systems are designed to help you:

- Control production cycle speed and efficiency

- Implement fast changes for more flexible operations

- Streamline your supply chain

- Increase cleanliness, particularly during the COVID-19 pandemic

- Create safer and more pleasant working conditions

Automate Your Food and Beverage Manufacturing Operations with AMD

AMD is a leading provider of specialty and custom automation equipment for our customers in the food and beverage industry and beyond. Whether you are in need of standard automated packaging equipment for your beverage bottling operation or complex robotic food production systems, we have the knowledge and experience to help you find the perfect solution. Our seasoned team of highly skilled engineers and technicians have completed more than 1,000 successful automation projects over the past 23 years. It is our aim to ensure that our automation systems meet and exceed even the most stringent customer expectations and industry guidelines.

Contact Our Experts Today!

At AMD, we are dedicated to creating state-of-the-art manufacturing solutions for our customers around the world. Each of our systems, both standard and customized, is built to exact specifications and subject to rigorous quality assurance testing for design, safety, functionality, and reliability. Using the latest technology, we create outstanding automation and robotics solutions that will enhance your production speed and efficiency without sacrificing quality. In fact, incorporating automation into your food and beverage processing will allow you to create higher quality products with a greater degree of repeatability, for a more profitable operation overall.

To learn more about AMD’s cutting-edge robotics technology for your food and beverage operations, contact us today or request a quote.