Flexible Assembly Machines

At AMD, we design and manufacture flexible assembly machines to enhance efficiency and adaptability in modern manufacturing. Our solutions integrate automated assembly, robotic work cells, and smart feeding systems to optimize production in high-mix, low-volume environments.

Why Choose Flexible Assembly Machines?

Traditional assembly lines can be limiting. Flexible automation systems enable manufacturers to handle product variations efficiently, reduce setup time, and increase output.

Key Advantages:

✅ Efficiency – High-speed automation reduces production time.

✅ Adaptability – Configure machines for multiple product types.

✅ Minimal Downtime – Quick-change systems simplify transitions.

✅ Quality Control – Integrated vision systems enhance accuracy.

Robotic automation cells are widely used in industries like automotive, aerospace, electronics, and medical manufacturing, offering reliable solutions for repetitive, high-precision, and complex tasks.

Flexible Feeding Solutions for Automated Assembly

In modern manufacturing, flexible feeding systems are essential for high-mix, low-volume production environments. Unlike traditional bowl feeders, flexible feeding systems allow for rapid part changeovers, handling a variety of components without requiring dedicated tooling.

Comparing Leading Flexible Feeding Systems

Several manufacturers dominate the flexible feeding market, including Asyril, FlexiBowl, and other alternatives. Below is a comparative analysis to help you choose the best solution for your automation needs.

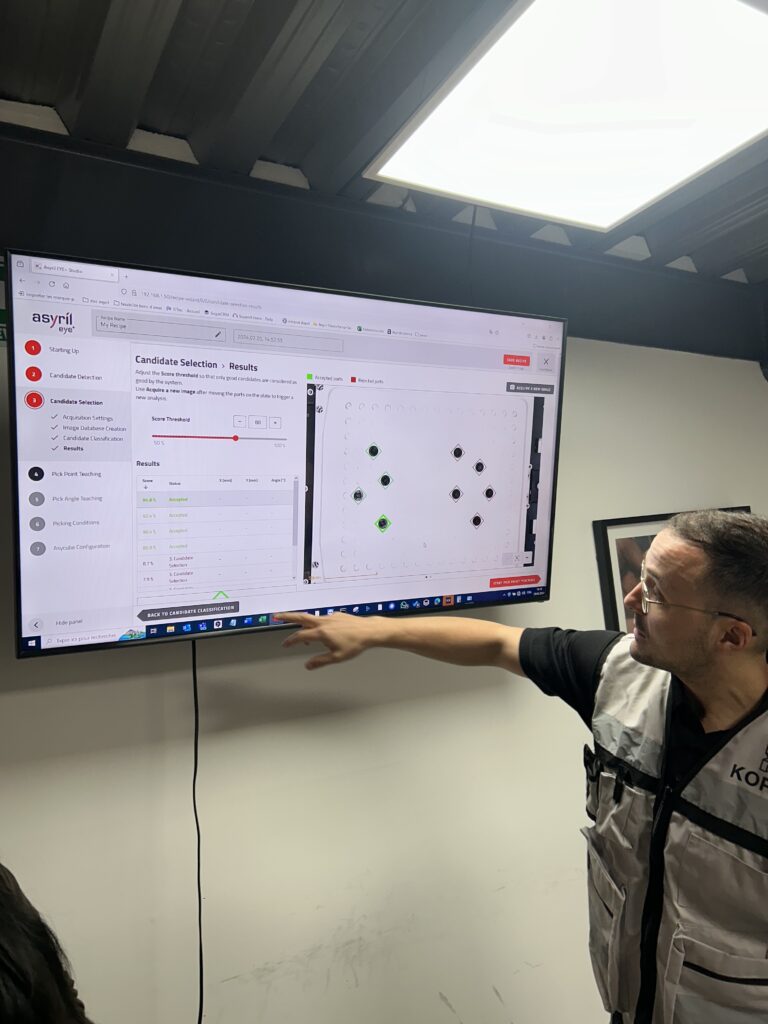

1. Asyril Flexible Feeding Systems

Asyril specializes in vibratory flexible feeders designed for high-speed and high-precision applications. Their 3-axis vibration technology ensures precise part movement and separation.

✔ Pros:

- High-speed feeding with advanced part separation

- Suitable for small to medium-sized parts (0.1–150mm)

- Seamless integration with vision systems and robotics

- Multi-part feeding capabilities for simultaneous processing

❌ Cons:

- Higher initial investment

- Best suited for precision applications (not ideal for heavy or large parts)

- Limited scalability for very high-throughput operations

Best for: Medical, electronics, watchmaking, and small-component assembly.

2. FlexiBowl Flexible Feeding Systems

FlexiBowl uses circular disc motion combined with vibration to efficiently handle a wide range of parts. Unlike traditional vibratory feeders, it minimizes part overlapping, reducing misfeeds.

✔ Pros:

- Handles a broad range of part sizes (1–250mm)

- Smooth part flow without excessive bouncing

- Easier integration with collaborative and industrial robots

- Lower maintenance compared to conventional feeders

❌ Cons:

- Slower cycle times compared to some 3-axis vibration feeders

- May require additional tuning for lightweight parts

- Slightly larger footprint than Asyril feeders

Best for: Automotive, consumer goods, and general industrial applications.

3. Other Flexible Feeding System Manufacturers

Epson IntelliFlex

✔ Pros: Integrated vision, easy programming, scalable for different parts.

❌ Cons: Higher complexity, limited configurations.

Omron AnyFeeder

✔ Pros: Strong vision-guided capabilities, ideal for high-speed automation.

❌ Cons: Requires Omron ecosystem for best performance.

RNA FlexCube

✔ Pros: Modular design, efficient for irregular-shaped parts.

❌ Cons: Limited availability in some regions.

Flexible Feeding is Not Always Bin Picking: Alternative Solutions

Precision Picking with Modular Tray & Pallet Loading Systems

While random bin picking relies on vision-guided robotics to handle scattered parts, structured picking solutions using modular tray or pallet loading systems offer greater accuracy, speed, and efficiency.

Why Choose Modular Tray & Pallet Loading for Robotic Picking?

Unlike AI-driven bin picking, modular tray-based systems allow robots to pick components from predefined positions, ensuring:

✔ Consistent & Predictable Picking – Eliminates extensive vision processing.

✔ Faster Cycle Times – Reduces search and orientation adjustments.

✔ Scalability & Flexibility – Modular trays can be reconfigured for different parts.

✔ Lower Error Rates – Precision placement minimizes mispicks.

Applications in Automated Manufacturing

🔹 Electronics & PCB Assembly – Robots can pick micro-components from precision-aligned trays for automated placement.

🔹 Automotive & Aerospace – Structured picking of fasteners, brackets, or small mechanical parts for assembly lines.

🔹 Medical Device Manufacturing – Ensures sterile, high-precision part handling.

🔹 Metal & Plastic Component Handling – Ideal for robotic polishing, machining, and secondary processing.

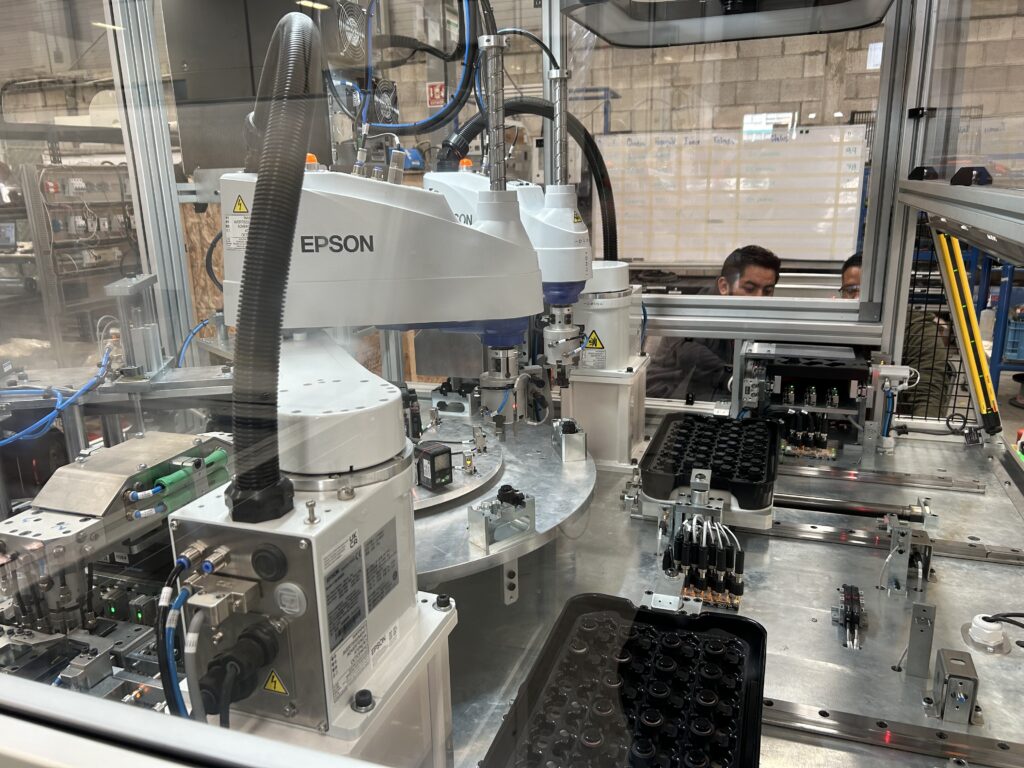

Integrated Robotics for Modular Pallet Picking

Our custom automation solutions integrate robotic arms, structured tray loading, and smart vision systems to deliver efficient, high-precision picking systems. Whether using fixed-position trays, interchangeable pallets, or automated loading stations, we design solutions tailored to your production needs.

Need Expert Guidance?

At AMD, we specialize in integrating flexible feeding solutions into custom automated assembly systems. Whether you’re considering Asyril, FlexiBowl, or another feeding solution, our team can help you design the best system for your production line.

Ready to revolutionize your production line? Contact AMD today to discuss your assembly cell requirements. Let us help you optimize operations, reduce costs, and improve performance with our innovative automation solutions.