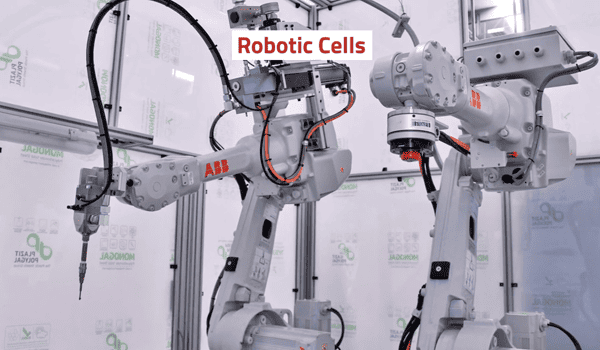

Robotic cells are a hallmark automation solution capable of performing complex tasks—such as assembly, welding, and inspection—that go beyond the capabilities of traditional automated machines.

Robotic cells are a hallmark automation solution capable of performing complex tasks—such as assembly, welding, and inspection—that go beyond the capabilities of traditional automated machines.

At AMD, we specialize in designing and creating custom robotic cells tailored to our customers’ specific needs, optimizing costs and increasing performance.

What is a Robotic Cell?

Robotic cells are specialized workstations that integrate one or more robots with additional equipment and systems to perform automated tasks within a defined workspace. These cells are designed to enhance productivity, precision, and safety in manufacturing and other industries.

Key Components of Robotic Cells:

Robot(s): The core element, performing tasks like assembly, welding, material handling, or inspection.

End Effectors: Tools or grippers attached to the robot arm to handle specific tasks.

Safety Systems: Fencing, sensors, and light curtains to protect operators and ensure compliance with safety standards.

Workholding Devices: Fixtures or tables to secure parts during processing.

Conveyors or Feeders: For part delivery and movement within the cell.

Control Systems: Software and hardware to program and manage robotic operations.

Peripheral Equipment: Additional tools like vision systems, testing devices, or marking machines.

Robotic automation cells are widely used in industries like automotive, aerospace, electronics, and medical manufacturing, offering reliable solutions for repetitive, high-precision, and complex tasks.

Robots in Robotic Cells

The choice of robot depends on factors such as available space, objects to be handled, and the required processes. Robotic cells may include various robot types:

- Industrial Robots: Shaped like human arms with six degrees of freedom, industrial robots offer exceptional flexibility, heavy-lifting capabilities, and the ability to perform complex operations.

- SCARA Robots: Selective Compliance Assembly Robot Arm (SCARA) robots are ideal for light-duty applications, offering high speed and efficiency for lighter objects.

- Delta Robots: Known as “spider robots,” Delta robots handle lightweight objects at high speeds and excel in short-range pick-and-place operations.

- Cobots: Collaborative robots (cobots) work alongside humans and are designed for safe interaction without the need for physical barriers. They often feature dual-arm designs for enhanced functionality.

Peripheral Equipment

Machines or equipment that support additional manufacturing steps like pressing, screwing, welding, marking, feeding, assembly, testing, and more. These tools can function as separate stations or be mounted directly on the robot for seamless integration. Some automated manufacturing cells require much more than robots to complete the required tasks. Some cells (like the one bellow) require Conveyors, Index Tables, Presses, Laser Markers and other auxiliary tools to complete the task.

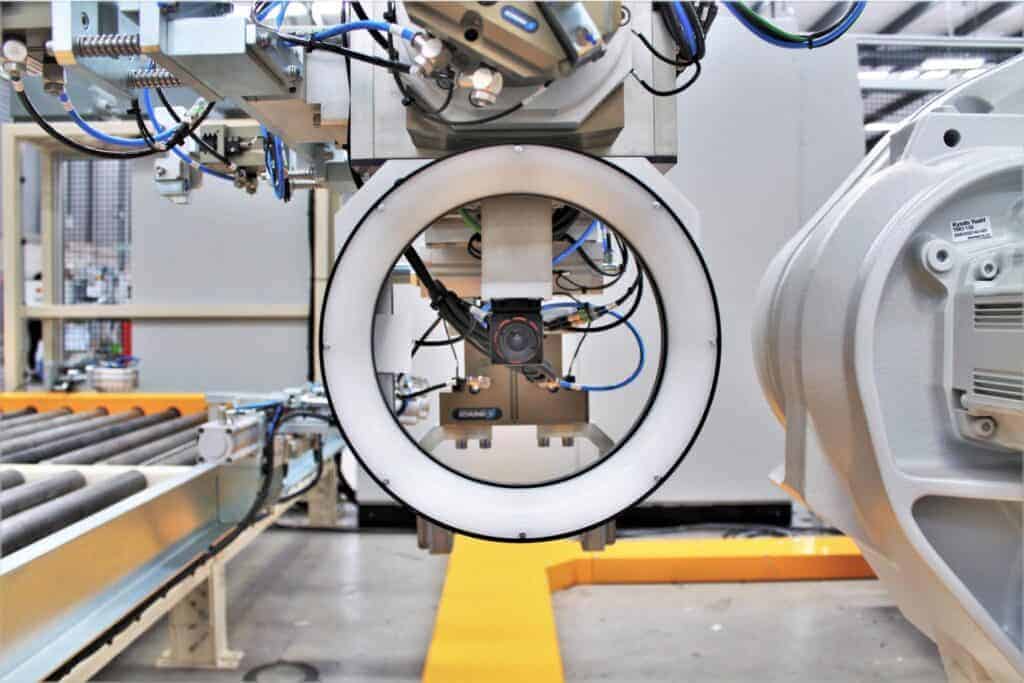

Vision Systems

Vision systems are critical in modern robotic applications as they guide robots during operations, validate the presence of components prior to assembly, inspect finished products, and perform other essential tasks. Robotic cells may feature:

- 2D Vision Systems: Ideal for basic object detection and placement.

- 3D Vision Systems: Enable advanced object manipulation, such as lifting workpieces from bulk storage and positioning them accurately into machines.

These systems empower robots to adapt to dynamic environments and improve overall efficiency.

Safety Systems

Robotic cells incorporate safety barriers to ensure operator safety and compliance with industry standards. Common safety barriers include:

- Physical Barriers: Metal enclosures that secure the robotic cell’s work area. Access is granted via alarmed doors that deactivate the robot during entry.

- Laser Barriers: These use strategically placed laser sensors to detect unauthorized entry. If a foreign object or person comes too close, the system slows down or stops entirely until the area is clear.

Safety barriers protect workers during operations, maintenance, and emergency situations, ensuring a secure work environment. Automated manufacturing cells must prioritize safety as an essential component. AMD ensures that its cells not only comply with local laws but are also designed to meet even the most stringent corporate safety standards.

When robots are not the right solution? – AMD also offers non robotic Automated Manufacturing Cells!

Many automated manufacturing cells can be built without robots. Robots may not be ideal for tasks requiring extreme speed, simplicity, or precision beyond their capabilities. They can be cost-prohibitive for small budgets, impractical in tight or harsh environments, and unsuitable for handling heavy loads or meeting certain regulatory constraints. Dedicated machinery or hybrid systems are often better suited for straightforward, high-speed, or highly specialized applications where flexibility isn’t a priority.

Some automated cells excel without robotics. For example, machines using index tables enable simultaneous process steps, making them ideal for high-volume applications.

Why Choose AMD for Robotic Cells?

Robotic cells significantly enhance productivity, safety, and efficiency for facilities handling assembly operations. At AMD, our experienced team of robotic specialists designs custom robotic cells that meet your unique operational needs. Whether you require solutions for standard assembly or specialized processes, we provide personalized systems that align with your goals.

Benefits of AMD’s Robotic Cells:

- Increased productivity

- Enhanced safety measures

- Optimized space utilization

- Cost-effective solutions

- Tailored designs for unique processes

Contact AMD for Robotic Cells Today

Ready to revolutionize your production line? Contact AMD today to discuss your robotic cell requirements. Let us help you optimize operations, reduce costs, and improve performance with our innovative automation solutions.