Advanced Manufacturing Development (AMD) is a North American industry leader in top-level automation and assembly. At AMD, we develop state-of-the-art manufacturing solutions with the highest design, quality, and functionality standards to match your needs. We strive to exceed your expectations with a balance in cost, quality, and technological level.

We collaborate closely with you to ensure we match our custom automation solutions to your business’s precise requirements. Our flexibility—gained from decades of working with all reputable PLC, robot, servo motor, and pneumatic commercial brands—allows us to adjust automation machines to your specifications.

We provide unmatched custom machining solutions, such as:

We provide unmatched custom machining solutions, such as:

- Leak tests

- Assembly

- Test systems

- Robotic cells

- Marking and traceability

- Welding

- Inspection with sensors or vision systems.

Custom Automation Equipment Solutions from AMD

At AMD, we design and develop top-quality custom automation equipment for our North American clients. Below are our top customizable automation equipment solutions.

Custom Assembly Solutions

Assembly is the process of bringing separate components into a single product, usually carried out in steps and each one can range from stapling two parts together to screwing, pressing, riveting, gluing, and more.

Benefits of Automated Assembly

- Quick turnaround

- Highest quality production

- Reduced labor costs

- Track and trace capabilities

- Increased production volumes

Our expert engineering team has experience and can design, fabricate and install anything from a manual, semi-automatic single machine to a complete automated assembly line made to exacting specifications.

At AMD, our main business for more than a quarter of a century has been the assembly of any type of product. Within each assembly line we can include cleaning processes to prepare the components for assembly, as well as different types of inspection, functional testing, leak testing, marking, and any type of custom station required.

Custom Leak Detection Solutions

Leak testing is a critical quality management step in the manufacturing process, specifically for hermetic products or components that are designed to hold gases or liquids up to an intended limit without leakage. Leak testing ensures quality and prevents dangerous conditions posed by leaks.

Benefits of Custom Leak Detection

- Prevents product leakage from containers

- Locate defects likely to cause further leaks

- Alerts you of the need for product maintenance

- Prevents contaminants from getting inside

Our leak detection solution and process play a vital role in various industries, such as the automotive industry. In addition, our expert team is highly experienced in dealing with various leak test stations.

Custom Test System Solutions

Test system automation incorporates advanced testing equipment into the manufacturing process without the need for operator handling or intervention. Testing automation quickly and accurately inspects, measures, verifies information, and evaluates the test results against predetermined criteria to ensure parts are fabricated within acceptable standards and tolerances. Our testing framework at AMD includes:

- Inspection

- Noise testing.

- Electrical testing

- Functional testing

- Leak detection

- Measurement

We design and create custom machinery to ensure quality testing and quality assurance. Our test systems are designed and customized to meet your predetermined criteria, standards, and requirements.

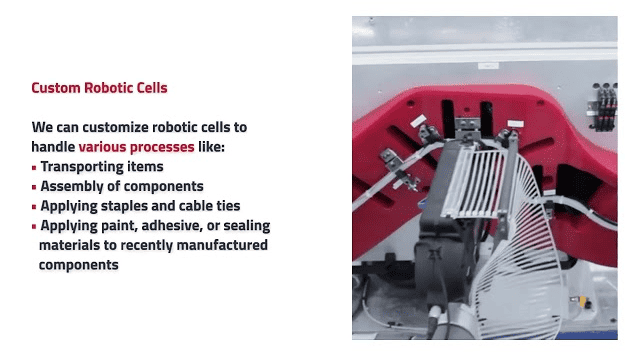

Custom Robotic Cells

Robotic cells hold all parts required for robots to perform tasks on assembly lines and complete the entire process inside the cell, resulting in faster production times. Such tools can be equipped with sensors, end effectors, tooling, part feeding mechanisms, safeguards and robot guidance with cameras, and more. We can customize robotic cells to handle various processes like:

- Transporting items

- Assembly of components.

- Applying staples and cable ties

- Applying paint, adhesive, or sealing materials to recently manufactured components.

Benefits of Custom Robotic Cells

- Efficiency

- Flexibility

- Consistency

- Cost-efficiency

- Improved safety

We design and build custom robotic cells for various applications based on your needs and requirements. Our custom solutions streamline costs and enhance production line performance.

Custom Welding Solutions

We offer multiple automated welding solutions, including but not limited to:

- Hot plate welding

- Robot welding

- Seam welding

- Spot welding

- MIG and TIG welding

- Ultrasonic welding

We design all our welding solutions to meet your requirements and needs. Unlike manual welding systems, automated welding systems provide several benefits, including:

- Better weld quality

- Lower scrap rate

- Reduced labor costs

If you have a specific welding need, we can suggest a tailored-made solution based on the production process, volume, variety of parts, and quality requirements.

Custom Marking & Traceability Solutions

Marking systems enable manufacturers to permanently add critical information to components that are required for compliance, tracing, quality assurance, and more. Our most common custom marking system solutions include:

- Micro percussion marking systems

- Laser marking systems

- Inkjet marking systems

- Stamp marking systems

These solutions provide several benefits, including:

- Facilitating quality assurance

- Product traceability

- Regulatory compliance

At AMD, we specialize in designing and constructing automated manufacturing systems customized to your unique needs.

In-House CNC Machining Supports Our Custom Automation Services

Currently, the industry faces an increased demand for faster, smarter, and more complex parts. We continuously commit ourselves to implement technical knowledge and project management skills to design according to your requirements and specifications.

Additionally, our experience in building automation equipment pushed us to build an in-house shop allowing us to make 95% of the parts used in our automated equipment solutions. With a fleet of 20 CNC machines, we can provide custom solutions to our equipment for you.

AMD’s Experience with Custom Automated Equipment Makes the Difference

We have decades of experience in the industry. As a custom manufacturer of automation equipment, our experience has helped multiple companies achieve their custom industrial automation goals. These include:

- Mabe

- Monroe

- Grammer

- Michelin

- Euro Tranciatura

- Bosch

- Nifco

- Tenneco

- Eaton

With our knowledge, we engineer, design, and build technically progressive machinery that solves application-specific challenges and surpasses the performance of any machine found in a standard product catalog. Contact us to learn more about our custom automation equipment solutions or request a quote for our products and services.