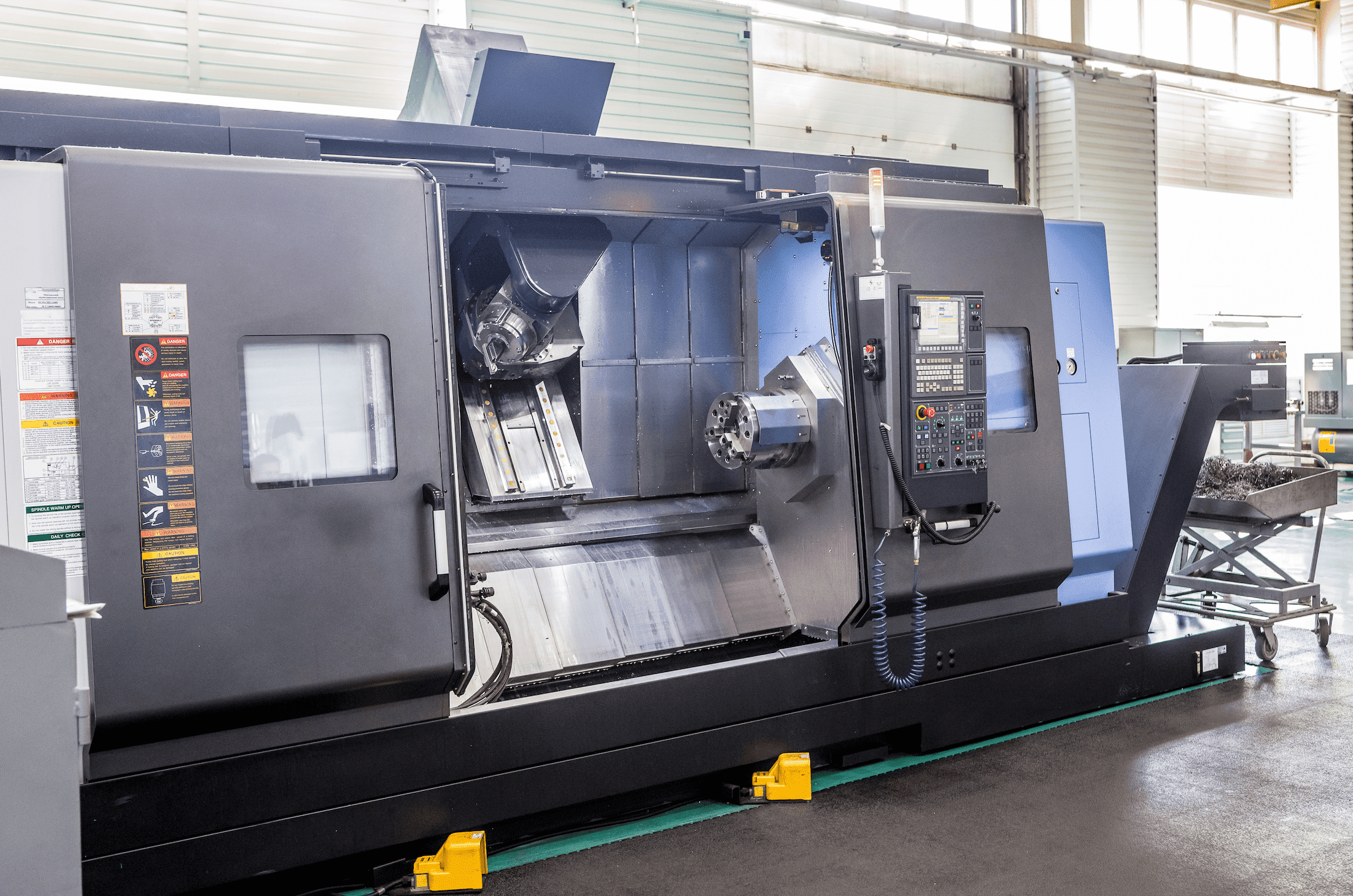

Computer numerical control (CNC) machining is a popular manufacturing method that utilizes programmable software dictating the movement of tools or workpieces. Depending on the specific technique, CNC machining can utilize mills, grinders, lathes, drills, routers, and more.

Learn more about the features, benefits, and applications of CNC machines.

What Is a CNC Machine?

CNC machining removes material from a stock workpiece through a series of processes including milling, drilling, turning, and other operations. These tasks ultimately create the shapes and features of the finished product.

Benefits of CNC Machining

CNC machining comes with a variety of benefits:

- Versatile capabilities: Utilizing advanced design software, CNC machines create components that cannot be replicated with manual machines. CNC machines can produce nearly any size, shape, or texture required. There are also certain machines that come with automatic tool changers or touch screens that further simplify production capabilities.

- Less labor: CNC machines only require a single programmer, who can upload the required designs to multiple machines. One operator can oversee each of these machines simultaneously. Manual methods require one skilled operator per machine, plus a supervisor for the team. Lower labor costs mean you can better optimize your workflow and focus more on your customers.

- High production: Design specifications and programming only need to be entered once, and the CNC machine can produce high quantities of goods. High production rates allow you to scale your business more efficiently.

- High precision: CNC machines produce consistent precision. Their computerized nature allows them to eliminate the risk of human error and achieve tolerances as tight as +/- 0.001 inch.

- Reliability: CNC machines can work all day, every day, including weekends and holidays. The only downtime necessary is for maintenance or repair.

- Design repeatability: After the initial set of specifications has been entered and the ideal prototype created, the CNC program can repeatedly retrieve the same design and create the product again. This master file will be accessible from that point on, regardless of operator changes or other external factors.

- Uniformity: With conventional machining, even the most capable engineers will produce slightly varying components. CNC machining produces parts exactly alike every time.

- Cost savings: The combination of specialization, precision, and speed equals significant savings for your company. The lower costs can be returned to the company to build your competitive advantage.

- Higher safety: CNC machines are far safer than conventional machines, where human workers are close to sharp cutting tools and other moving parts. CNC machining enables them to keep a safe distance from the production process.

- Low maintenance: G-code CNC software automatically updates itself as needed. CNC machines typically don’t require much more maintenance than regularly changing cutting instruments and doing some light cleaning. These maintenance services can be performed by the operator—no need for outside professionals.

Industrial Uses of CNC Machining

CNC machines are useful for producing parts for many sectors, including:

- Aerospace

- Agriculture

- Dental

- Publishing

- Automotive

- Military

- Construction

- Electronics

- Metalworking

- Firearms

- Hospitality

- Manufacturing

- Production

- Transportation

CNC Machining Services from AMD

Advanced Manufacturing Development (AMD) has been in the part machining industry for 25 years. We manufacture around 95% of the machined parts we use, and every part goes through a quality control process that ensures proper tolerances and high quality. Our machining facility houses over 20 CNC machines, specializing in medium-sized components (64” x 32” x 30”). Our lead time is generally five to 10 days.

To get started on your custom CNC machining project, please request a quote today.

1 Comment

Allie

Wonderful views on that!