Technology is continuously revolutionizing the electrical sector, providing us with new ways to build infrastructure, map cities, and use energy. The electrical industry provides electricians to perform work on various sites and sell, install, and service electrical equipment.

Though often used interchangeably, electrical and electronic devices have subtle differences. The main difference is that electrical devices take electrical energy and transform it into different energy forms such as heat, sound, or light, while electronic devices manipulate the flow of electrons to execute specific tasks.

Electrical & Electronic Devices from AMD

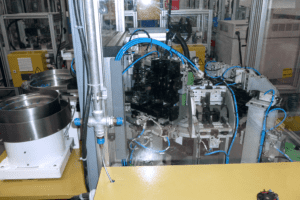

At AMD, our expertise with circuit board quality control equipment has allowed us to develop quality tests to ensure proper circuit board functioning. The first test we offer incorporates vision systems to ensure that all required components are in the card and that they are properly connected. These cameras can be used to verify the behavior of smart sensors, like accelerometers and gyroscopes.

We also offer functional testing in which we send the appropriate signals to trigger functions on the board. We then assess the board’s response against the required standards.

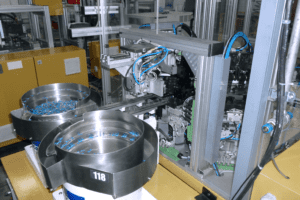

We work on the integration of sensors, moto protectors, harnesses, connections, and other equipment for the electronic sector. AMD is capable of automating packaging machinery by using a robot to arrange boards or pieces in trays in specified patterns.

AMD’s Electrical Automation Solutions

At AMD, we offer customized solutions to our customers in the electrical and electronic industries. Some of our capabilities include:

Wire & Cable Assembly

We can quickly and accurately reduce, strip, and assemble electronic wires and cables for a range of applications.

Assembly & Testing

Assembly refers to processes performed on any component of a product. It includes many secondary processes like trimming or connecting components. Automated testing systems execute all required checks on a device or product without requiring user interaction or handling. Automated testing technology quickly and perfectly executes measurements and compares the test results against defined standards to ensure they fall within the acceptable parameters.

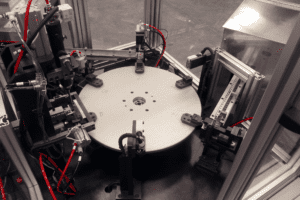

Automated Parts Handling & Orientating

Automated parts handling and orientating arranges parts into predetermined positions from arbitrary starting points. It is critical to accurately orient parts to the tightest tolerances to ensure proper machine functioning. Misalignments can cause blocks in equipment, resulting in costly downtime.

Robotics

Robotic cells are capable of performing more complex tasks such as assembly, leak monitoring, welding, and testing when compared to conventional automated machines. In addition to performing tasks that are difficult or impossible for humans, robotic cells can be set up and activated with a few simple clicks of the mouse.

Vision Inspection & Quality Control

Visual inspection is a form of quality control in which components on the production line are analyzed for defects or imperfections. This form of quality control has been proven to detect the most hidden flaws during production.

Pick and Place

Pick and place systems enhance the effectiveness of surface mount technology. These systems enable components to be quickly and correctly positioned on a printed circuit board, increasing output and precision.

Poka Yoke

Often used in process analysis procedures, poka yoke is the use of an automatic device or method that either eliminates the risk of making an error or makes the mistake instantly evident once it occurs.

Automate your Electrical Devices with AMD

At AMD, we improve the reliability, safety, and profitability of our clients’ manufacturing applications with high-performance, economical engineering automation solutions. If a standard machine doesn’t fit your application, we will create a custom-engineered solution for you. Contact us today for more information.