For years, we purchased CNC machining services from third parties, but when unreliable deliveries and inferior quality standards started impacting our automation operations, we decided to begin CNC machining metal parts ourselves. Our CNC shop has grown significantly and we now manufacture close to 50,000 pieces of custom components for our machines and clients every year.

Our CNC machining services:

- Focus on tight tolerances and quality assurance – Every part undergoes rigorous inspection from our quality department before shipping.

- Strictly adhere to deadlines – Missed deadlines affect your bottom line. As such, we provide clear communication regarding delivery times so you can plan accordingly.

- Offer competitive prices – We run highly efficient production operations with 94% of all parts we manufacture falling within tolerance requirements to ensure that our customers never pay for production inefficiencies.

- Are ideal for low production volumes, spare parts, and prototypes.

- Machining multiple materials etc. -wide range, include the materials: In AMD we can adapt to the necessities of our customers, nevertheless here are some of the most common materials we use:

- a)Steel: 1018, 4140, A36, SS 304, D2

- b)Aluminum: 6061, 7075

- c)Copper & copper allloys

- Brass & brass alloys

- d)Plastics: Acetal, Nylamid, nylon, Teflon, and UHMW polyethylene

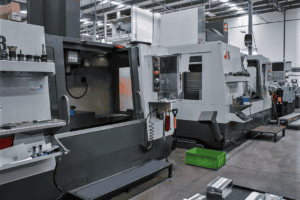

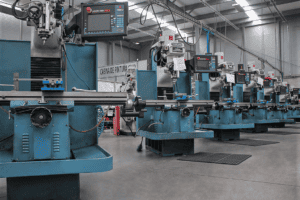

AMD’s CNC Machines

At AMD, we run a competitive machining facility with over 20 CNC machines and we manufacture around 95% of the machined parts we use for automation solutions. Every part undergoes a comprehensive quality control process to ensure high quality and proper tolerances are met.

Our CNC machines have been designed to work with various materials. This includes metals such as aluminum, hard steel, special aluminum alloys, steel, steel alloys, copper, brass, copper alloys, and brass alloys. We also work with plastics such as nylon, Teflon, and UHMW polyethylene and can work with other materials according to your unique requirements.

AMD’s Provides Quality You Can Count On

At AMD, we offer CNC machining services in Mexico and Fort Worth and are staffed with a highly skilled team of 20 CNC machinists with more than 100 years of combined CNC machining experience. Working with AMD on your custom CNC machining project means you’ll get:

- Level of quality: The high-precision ability of our custom CNC machining services ensures you get exactly what you need — a high-quality product.

- Reliable delivery times: The CNC machine is set to follow the preset instructions, resulting in a reduced chance of error during production. Our lead time is typically 5-10 days.

- Cost savings: Our custom CNC metal machining services are very competitive in terms of pricing/quality, and our fast response times translate to considerable cost savings for you.

What is CNC Machining?

CNC machining is a manufacturing process that employs computer-controlled instructions to operate and manipulate production equipment to cut and shape materials into custom parts and designs. The process can control a range of highly technical machinery, including lathes, mills, grinders, and CNC routers.

Every CNC machine consists of three parts: a command center, a drive system, and a feedback system. Most are fully automated, allowing you to create components or parts that would otherwise be challenging to produce manually. With CNC machining, you can accomplish three-dimensional cutting tasks in a single set of prompts. All they need is digital files with instructions detailing cutting trajectories and tooling. When a CNC system is activated, the cuts are programmed into the software and translated to corresponding tools and machinery, which carry out the dimensional tasks as specified.

Benefits of Custom CNC Machining

Custom CNC machining involves creating parts according to a customer’s specification or parts that meet a specific purpose. For example, custom machining may be the best solution if the desired part is nonstandard and not available from a supplier, or the part has unique features not found on standard parts.

Our custom CNC machining services at AMD allow us to produce high-quality parts that meet your specifications and requirements. We work closely with you to ensure that we produce exactly what you envision quickly and efficiently.

Custom CNC Machining with Advanced Manufacturing Development, Inc.

At AMD, we recognize the immense value both in cost and quality that CNC machining services provide our clients. With decades of combined experience in CNC machining, a fully functioning machining facility with 20 CNC machines, and a team of highly-qualified machinists, AMD can handle all your custom CNC metal machining needs. We specialize in manufacturing medium size pieces (dimensions up to 64″ x 32″ x 30″) with tolerances up to 0.001″ and lead times as low as 5-10 days. Contact us today to request a quote and discover how our custom CNC machining services can bring value to your business.