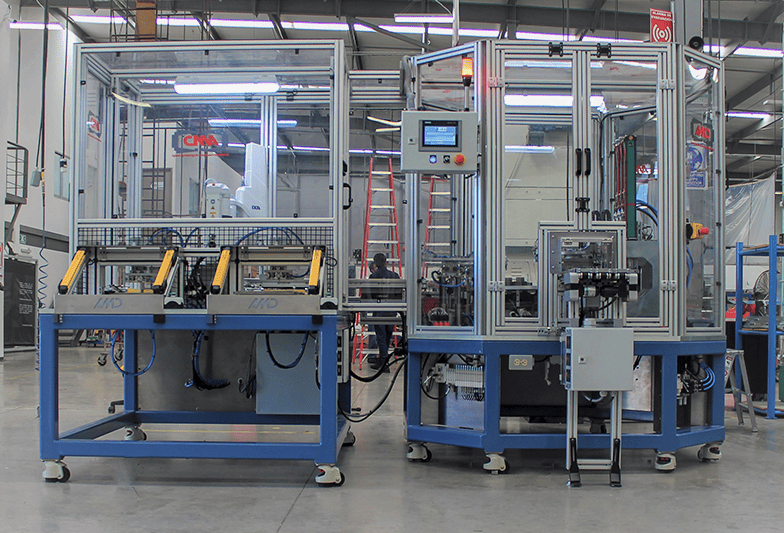

AMD is an industry leader in turnkey, fully customized solutions for our manufacturing customers. The experienced engineering team at AMD can construct anything from a single machine to a complete automated assembly line. We also design machines to fit in with preexisting automated assembly lines. Every project at AMD is unique to each client’s specifications, with whom we work closely with to ensure that we develop exactly what they envision.

What Is Assembly Automation?

Assembly is any process that affects any aspect of the product. It can range from using a laser to trim excess material from a part to stapling two parts together. Examples of assembly automation orders we have fulfilled include constructing a six-meter long oven designed to heat plastic to relief stress and marking parts with codes for tracking purposes.

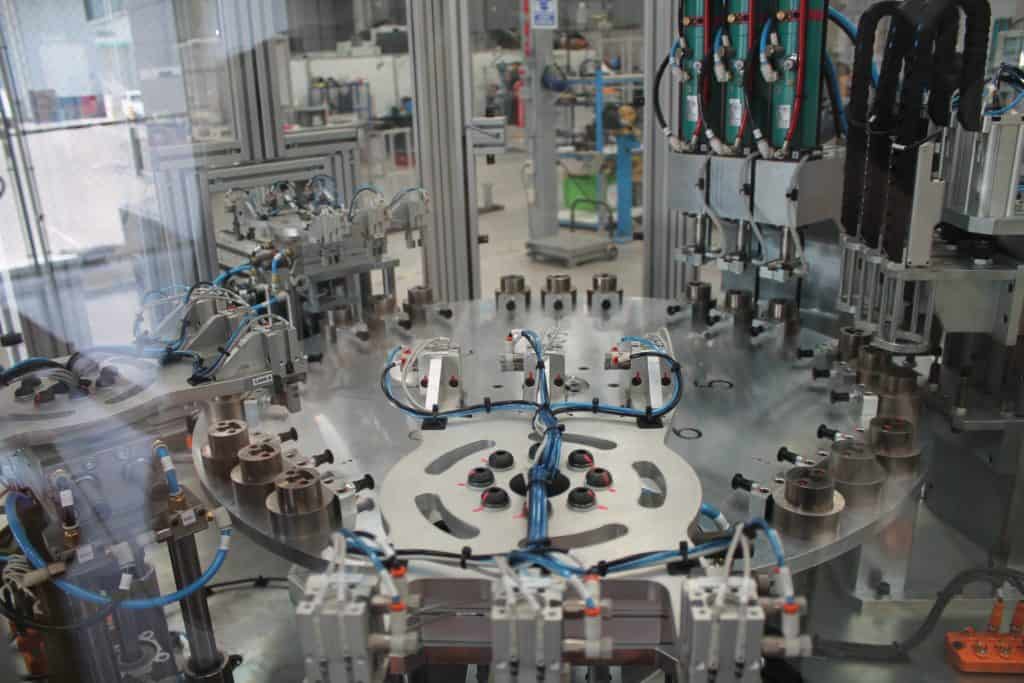

Assembly lines are rarely ever sold alone and are typically combined with testing or cleaning stations for quality control. Screwing, pressing, riveting, and gluing are assembly solutions that can be as manual or automated as the customer requires. At AMD, we focus on customer satisfaction and can use any brand of PLC and robot that satisfies our customers’ assembly needs.

The Benefits of Automated Assembly

Assembly line automation provides numerous benefits to companies, including:

- Faster Turnaround. Quicker turnaround is achieved since automated assembly has the ability to combine several assembly and production processes into one single operation.

- Higher Quality. Automation offers higher quality production by completing tasks efficiently, accurately, and with a high degree of conformity and repeatability, all of which are difficult to achieve when performed manually.

- Reduced Labor Costs. Automated assembly offers both direct and indirect labor cost savings. The direct savings include freeing up time for employees to complete tasks that are unable to be automated. Indirect labor cost savings include reducing material handling, minimizing orientation and training time, and improving finished product inventory.

- Track & Trace Capabilities. Automated assembly gives manufacturers an efficient way to track every component throughout the assembly process, which helps identify the source of bottlenecks and other quality issues.

- Increased Volume. High production speeds achieved when using automated assembly allow companies to raise production volumes, which increases the likelihood for profitability.

Outsource Your Engineering Department With AMD

Advanced Manufacturing Development customizes machines for the unique machinery, brand, and specification requirements of each customer. We have spent years developing close relationships with suppliers of assembly components who give us focused, continuous support to ensure that we are applying the component correctly. Our key to success is working with our customers and suppliers.

AMD’s team of professionals possess in-depth knowledge of all assembly components and help clients deliver quality products quickly and efficiently. Consider us your integral engineering department capable of finding solutions for all your assembly needs.